Flow measuring pipe segment for small-caliber ultrasonic heat meter

A flow measurement and ultrasonic technology, applied in the field of sensing technology and flow measurement devices, can solve the problems of sealing, pressure resistance, pressure loss, anti-blocking, anti-corrosion and scaling cleaning, the relative size of components is difficult to meet the position accuracy requirements, and the reflection inside the pipe It can reduce the processing cost, improve the flow performance, and reduce the operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

[0017] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

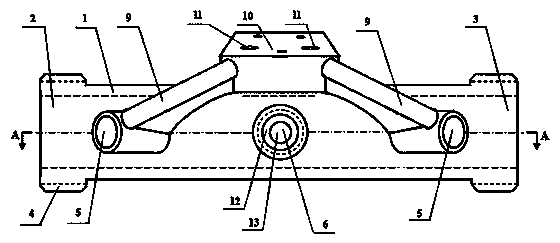

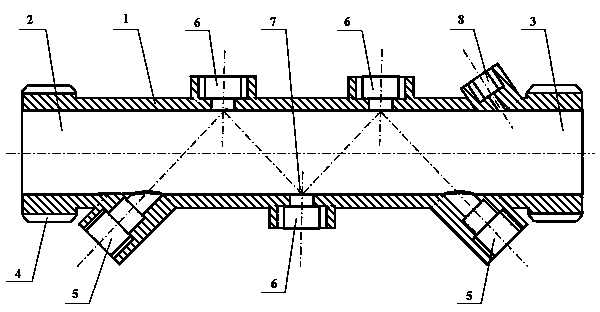

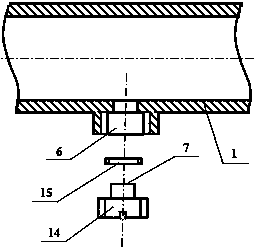

[0018] Such as Figure 1-3 As shown, the straight pipe section 1 for flow measurement is integrally cast from copper alloy. The straight pipe section 1 is cylindrical as a whole and adopts a straight-through structure with the same diameter. The straight pipe section 1 is provided with two transducer mounting holes 5, Three reflective plug installation holes 6, one temperature sensor installation hole 8, two wire threading pipes 9 and one converter installation seat 10, and the inner surface of the straight pipe section 1 is polished.

[0019] The straight pipe section 1 is provided with two transducer installation holes 5 and three reflection plug installation holes 6, and the included angle between the centerline of the transducer installation holes 5 and the centerline of the straight pipe section 1 is 45° o , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com