Double well construction method for salt cavern gas storage

A technology for gas storage and salt caverns, which is applied in earthwork drilling, mining equipment, mining equipment, etc. It can solve problems such as thick interlayers in salt layers, high-grade salt rocks, difficult problems, etc., so as to increase the speed of cavity building and increase the The effect of dissolution volume and increasing water injection displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

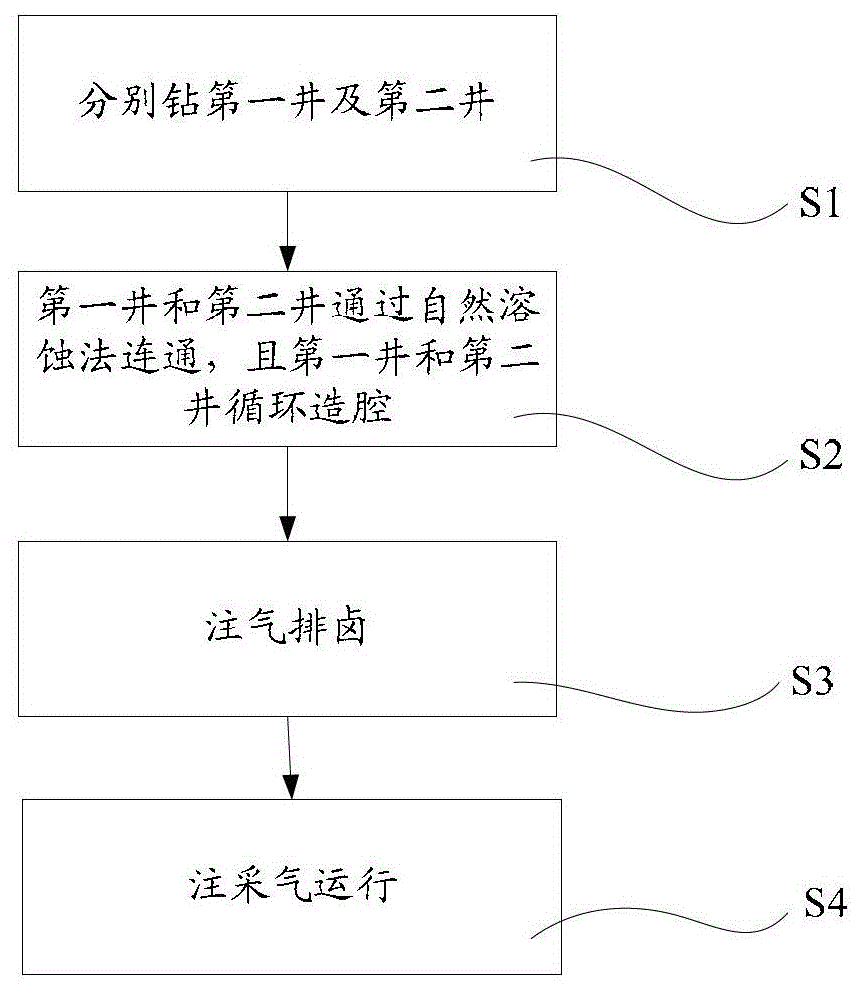

[0019] Please refer to figure 1 , the salt cavern gas storage double well construction method of the present invention comprises the following steps:

[0020] The first step S1: Drill the first well and the second well respectively, and the horizontal distance between the centerlines of the first well and the second well is 15m-30m. In this embodiment, the first well and the second well are two open vertical wells.

[0021] Preferably, in this embodiment, the inclination angles of the first well and the second well are both less than or equal to 1.3 degrees to 1.5 degrees, and the maximum full angle change rate does not exceed 1.25 degrees / 25m; the boreholes of the first well and the second well The horizontal displacement of any poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com