Dynamic balance control device for tension of warps of weaving machine

A technology of dynamic balance and control devices, which is applied in looms, textiles, textiles and papermaking, etc., can solve problems such as unstable tension control, achieve stable output, improve fabric quality, and prevent fluffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

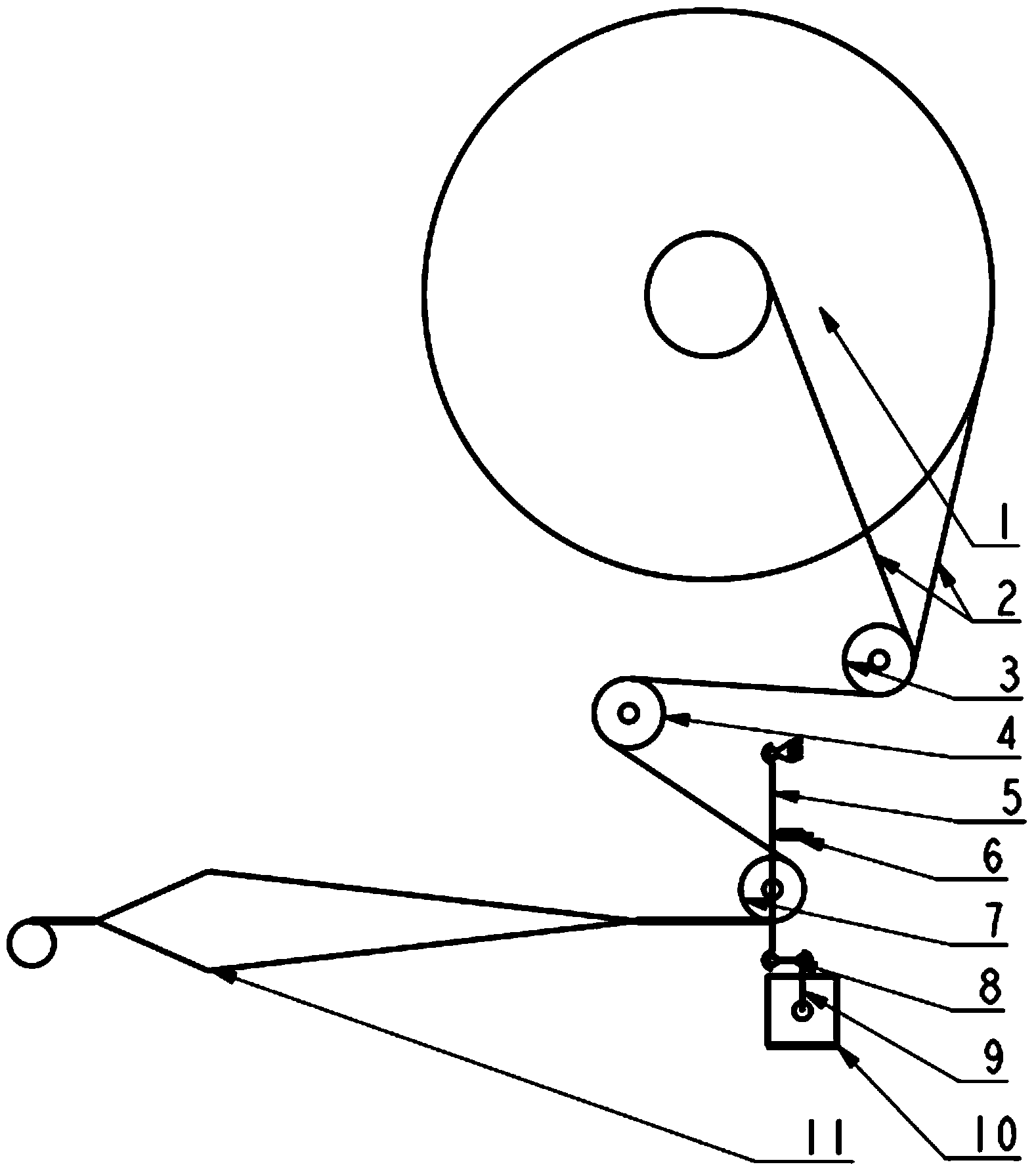

[0015] Such as figure 1 As shown, the loom warp tension dynamic balance control device includes a pile warp beam 1 and a yarn 2 wound on the pile warp beam 1, and the figure shows the yarn when the beam is full and when the beam is full position, the yarn 2 is drawn from the wool warp beam 1, and then the warp is guided to the fabric weaving 11 by the fixed guide roller shaft group for weaving, and the warp thread movement is arranged between the wool warp fixed guide roller shaft group and the fabric weaving 11 Guide roller 7, described warp movable guide roller 7 is installed on a swing lever 5, and the head end of described swing lever 5 is hinged on a fixed head, and the tail end of swing lever 5 is connected with a link mechanism, and link mechanism Driven by a servo motor 10, a displacement sensor 6 is provided on one side of the swing rod 5 to detect the gap between the swing rod 5 and the displacement sensor 6, and the servo motor 10 adjusts the swing angle of the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com