Production method of high-purity dimethyl fumarate

A technology of dimethyl fumarate and its production method, which is applied in the field of chemistry and chemical engineering, can solve problems such as unresolved production cost and quality problems, high cost of ionic liquids, and no economic advantages, etc., so as to reduce recrystallization steps and reduce costs The effect of large range and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

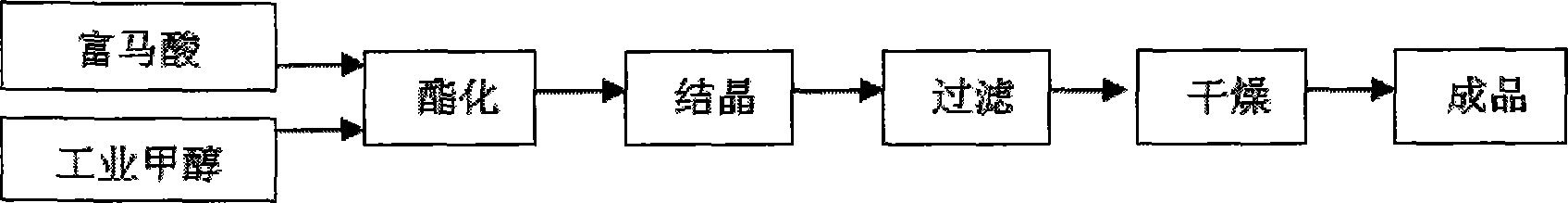

Method used

Image

Examples

Embodiment 1

[0035] to 2m 3 In the enamel reactor, put 500 kg of industrial methanol, 50 kg of 98% concentrated sulfuric acid, and 500 kg of dried industrial waste fumaric acid in sequence, and then pass steam into the jacket to raise the temperature to 50 °C, start stirring, continue Raise the temperature to 90°C, add 1,000 kg of methanol dropwise, and produce through the condenser at the same time. The output enters the jacketed crystallizer, cools and crystallizes, and is filtered and dried by a centrifuge to obtain 158 kg of the product, which has a purity of 99.65 after chemical analysis. %. The calculated yield is: 25.44%.

Embodiment 2

[0037] Add 500 kg of dried industrial waste fumaric acid to the reactor of Example 1. Maintain 90-110°C. According to the method of Example 1., add 5000 kg of methanol dropwise to obtain 356 kg of product. The calculated yield is: 57.34%.

Embodiment 3

[0039] In the reactor of embodiment 2., drop into 500 kilograms of industrial waste fumaric acid through drying again, maintain 90~110 ℃, according to the method for embodiment 1., drop in 5000 kilograms of methanol, including 1000 kilograms of new methanol and 4000 kilograms of methanol are reclaimed to obtain 587 kilograms of product. The calculated yield is: 94.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com