Single coil VPI process

A coil and process technology, which is applied in the field of vacuum pressure impregnation process, can solve the problems that large-scale hydroelectric generators are difficult to implement VPI process, and achieve excellent storage stability, high mica content, and good electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

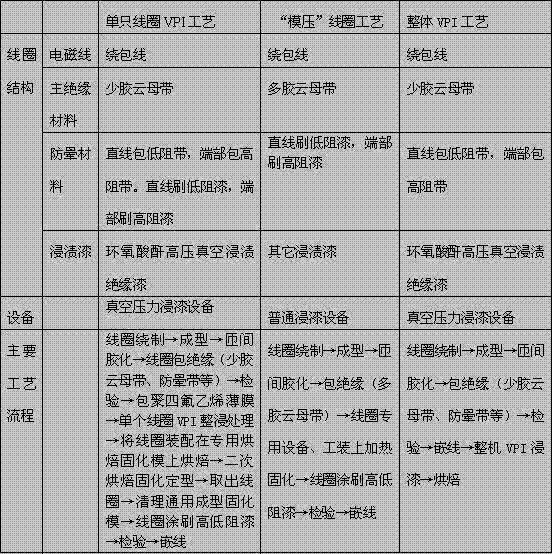

[0028] The VPI process flow for manufacturing a single coil coil includes the following steps:

[0029] Winding→wrapping protective tape→sand head→expansion→shaping→turn-to-turn gelation→removing protective tape→wrapping lead wire→wrapping less glue mica tape→wrapping anti-halation tape→wrapping polyester heat shrinkable tape at the end→inspecting→ Flat-wrapped PTFE film→Single coil VPI dipping treatment→Assemble the coil on a special baking curing mold→Baking→Take out the coil→Clean the general forming curing mold→Coil coating with high and low resistance paint→Inspection.

[0030] The process flow of stator "no hanging handle" inlaid wire is as follows:

[0031] Stator core trimming and cleaning treatment (slots must not have sharp corners) → Spray low-resistance paint on stator core slots → Install positioning end hoops → Insert the lower side of the first coil into the position of the core slot, and place the upper side on the shelf Upper→Insert the coils one by one, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com