Marine cable seal connector in deep water environment

A cable sealing and connector technology, applied in the direction of connection, parts and circuits of the connection device, can solve the problems of damage to the seal, deformation, soft seal, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

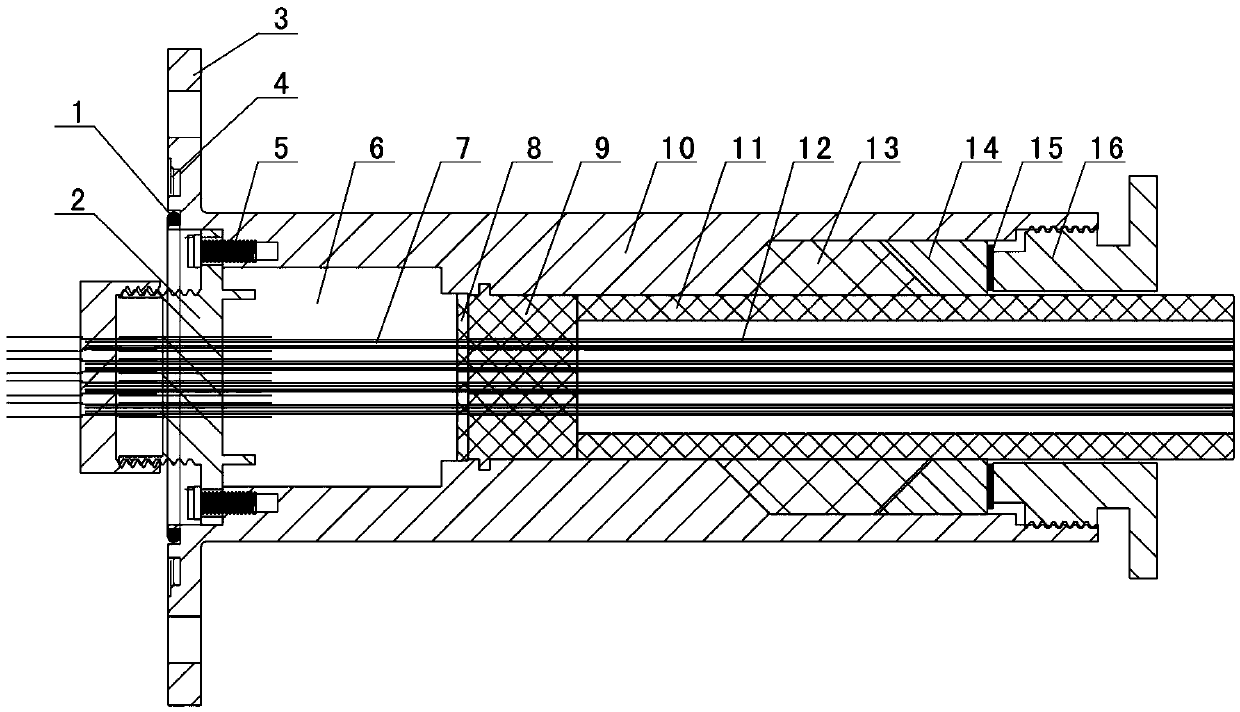

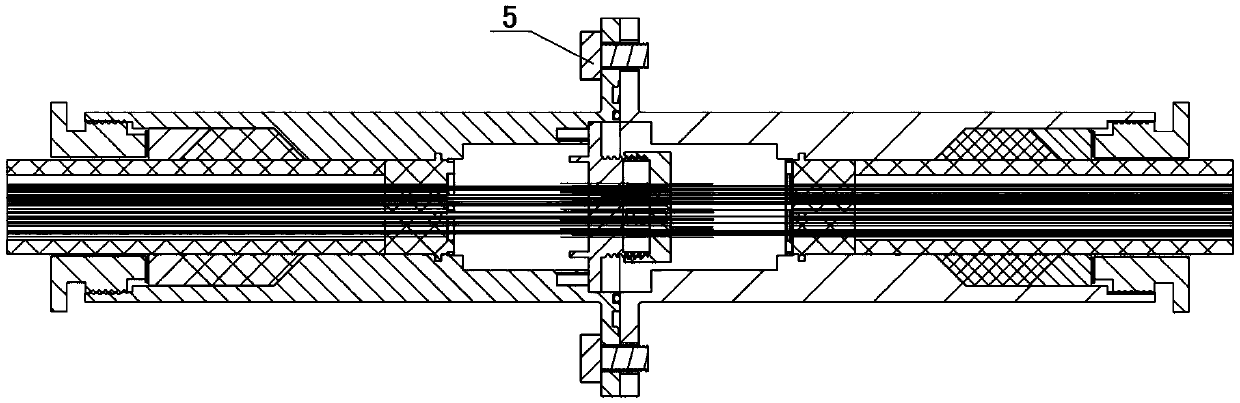

[0024] like figure 1 and figure 2 As shown, in order to facilitate the description of the structure of the sealed connector, figure 1 and figure 2 Both of them show the marine cable 11; the marine cable sealing connector in the deep water environment of the present invention includes a sleeve 10, a compression nut 16, a compression ring 14, a rubber sealing ring 13 and a separation disc 8, and the first part of the sleeve 10 end( figure 1 the left end of the figure 2 The right end of the middle) is provided with a flange 3 for connection, the second end of the sleeve 10 ( figure 1 the right end of the figure 2 The left end of the center) is provided with an internal thread, and the external thread of the compression nut 16 is connected with the internal thread of the sleeve 10. In the through hole of the sleeve 10, the middle section is a small diameter through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com