Copper bush of bearing seat of anchor machine

A bearing seat, copper sleeve technology, applied in the rigid bracket, bearing element, shaft and bearing of bearing components, can solve the problems of anchor chain skipping, anchor windlass impact, abnormal drop, etc., to avoid movement and operate safely. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

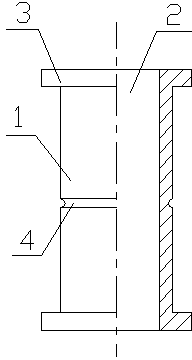

[0009] Such as figure 1 As shown, the copper sleeve of a windlass bearing seat of the present invention includes a copper body 1, the copper body 1 is a hollow cylinder structure, and the through hole in the middle is a shaft hole 2, and the two ends of the copper body 1 Cylindrical stoppers 3 are provided respectively, the stoppers 3 and the copper body 1 are integrally structured, and the end faces of the two are flush, and the middle part of the cylinder body 1 is provided with an annular groove 4, and the ring groove 4 The section is a semicircle with a radius of 5 mm.

[0010] When the present invention is working, it is first installed in the bearing seat of the windlass, the bearing seat is in clearance fit with the copper body 1 and the stopper 3, and then the main shaft of the windlass is inserted into the shaft hole 2, and the bearing seat at the corresponding position above the annular groove 4 The screw is screwed into the threaded hole on the top, and the coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com