Ceramic spraying device

A technology of spraying device and ceramics, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of excessively thick spraying layer and uneven ceramic powder spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

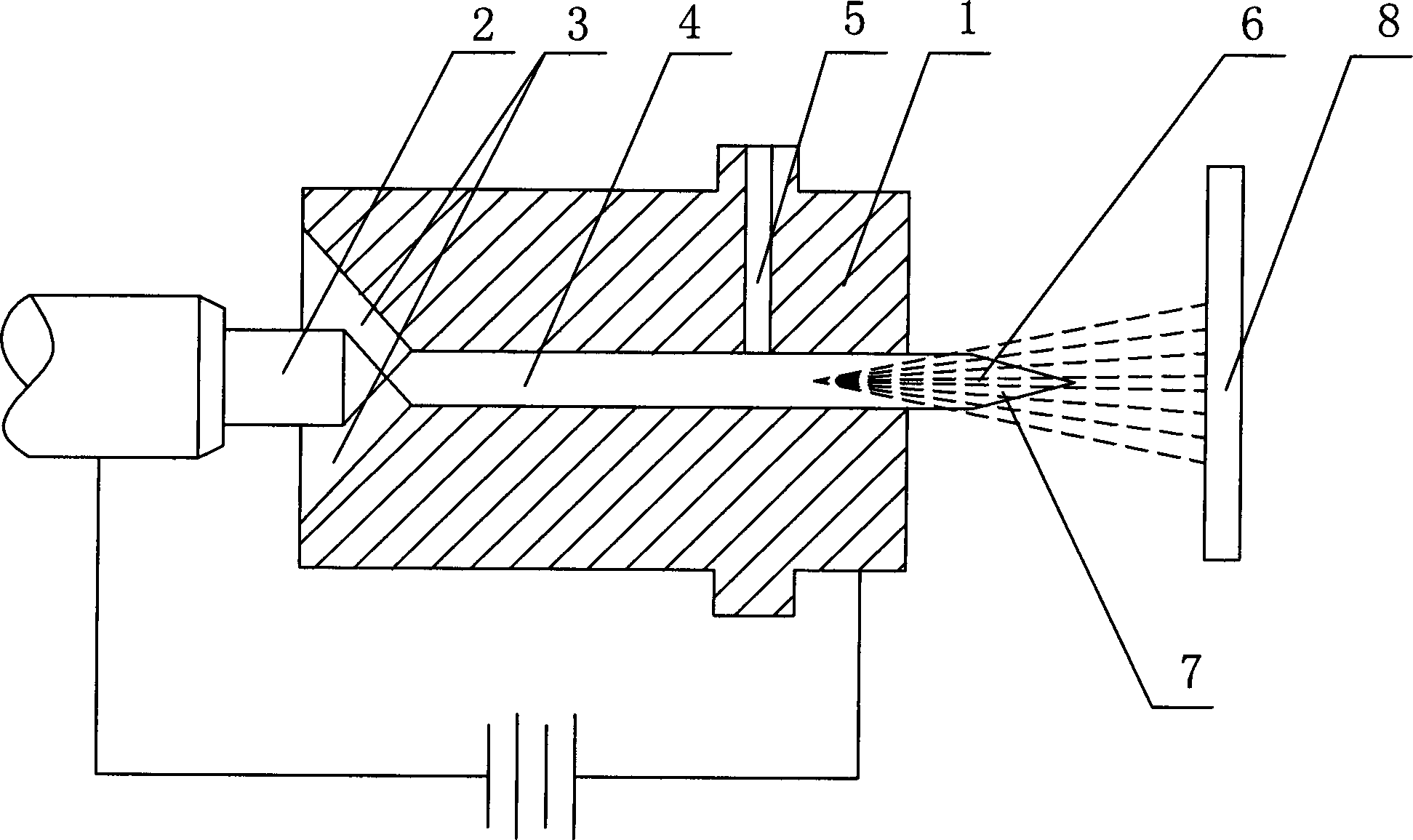

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the present invention includes a nozzle 1 made of metal, the front end of the nozzle 1 is connected with a cathode 2, and a DC voltage is added between the nozzle 1 and the cathode 2; in the nozzle 1, an air inlet channel 3 is opened on both sides of the cathode 2; Inside 1, the cathode 2 is axially provided with a flame channel 4 leading to the rear end of the nozzle 1, and the flame channel 4 is connected to the air intake channel 3; inside the nozzle 1, at the outlet of the flame channel 4, there is a powder inlet hole 5, and a powder inlet hole 5 It communicates with flame channel 4.

[0013] When DC voltage is applied to the cathode and the metal nozzle of the present invention, nitrogen, argon, helium or their mixed inert gas is introduced into the intake channel 3 simultaneously, and then ignited i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com