A method of production of glycerin fuel

A production method and technology of glycerin, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve a large amount of acid liquid, acid residue and other problems, achieve the effect of lowering the freezing point, increasing the cetane number, and avoiding pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

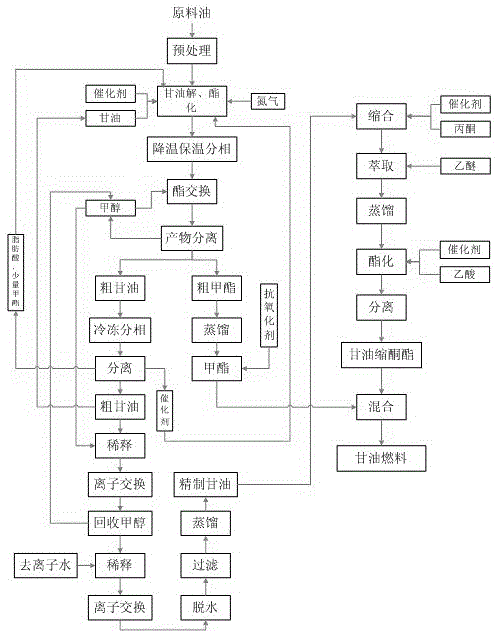

Method used

Image

Examples

Embodiment 1

[0040] Raw material: gutter oil

[0041] 1. The pretreatment steps of raw oil are as follows:

[0042](1) Acid refining: the raw material oil is pumped into the heater by the raw material pump to preheat to 65-70°C and then enters the mixing tank, adding 0.2% phosphoric acid of the raw material oil quality to stir and condition, and then naturally cooled to below 40°C;

[0043] (2) Flocculation and sedimentation: Heat the hydrated oil to about 70°C, mix polyaluminum chloride (PAC) with 1% waste oil mass and polyacrylamide (PAM) with 0.5 waste oil mass with 5% waste oil mass After dissolving in hot water (80-90°C), add it to the mixing tank, stir and mix with the waste oil for 10 minutes, transfer to the settling tank and let it settle for about 1 hour;

[0044] (3) Separation and dehydration: the lower layer of colloid is released, and the upper layer of oil is dehydrated by a thin film evaporator to a water content of less than 0.1%;

[0045] (4) Filtration: The dehydrated ...

Embodiment 2

[0072] Raw material: hogwash oil

[0073] 1. The pretreatment steps of raw oil are as follows:

[0074] (1) Acid refining: the raw material oil is pumped into the heater by the raw material pump to preheat to 65-70°C and then enters the mixing tank, adding 0.2% phosphoric acid of the raw material oil quality to stir and condition, and then naturally cooled to below 40°C;

[0075] (2) Flocculation and sedimentation: Heat the hydrated oil to about 70°C, mix polyaluminum chloride (PAC) with 2% of the mass of waste oil and polyacrylamide (PAM) with 1% of the mass of waste oil and 10% of the mass of waste oil After dissolving about % hot water (80-90°C), add it to the mixing tank, fully stir and mix with the waste oil for 10 minutes, transfer to the settling tank and let it settle for about 1 hour;

[0076] (3) Separation and dehydration: the lower layer of colloid is released, and the upper layer of oil is dehydrated by a thin film evaporator to a water content of less than 0.1%;...

Embodiment 3

[0103] Raw material: acidified oil

[0104] 1. The pretreatment steps of raw oil are as follows:

[0105] 1) Acid refining: the raw material oil is pumped into the heater by the raw material pump to preheat to 65-70°C and then enters the mixing tank, adding 0.2% phosphoric acid of the raw material oil quality to stir and condition, and then naturally cooled to below 40°C;

[0106] 2) Flocculation and sedimentation: heat the hydrated oil to about 70°C, mix polyaluminum chloride (PAC) with 3% of waste oil mass, polyacrylamide (PAM) with 2% waste oil mass and 15% waste oil mass After dissolving in hot water (80-90°C), add it to the mixing tank, stir and mix with the waste oil for 10 minutes, transfer to the settling tank and let it settle for about 1 hour;

[0107] 3) Separation and dehydration: the lower layer of colloid is released, and the upper layer of oil is dehydrated by a thin film evaporator to a water content of less than 0.1%;

[0108] 4) Filtration: The dehydrated o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com