Nickel-coordination polymer and preparation method thereof

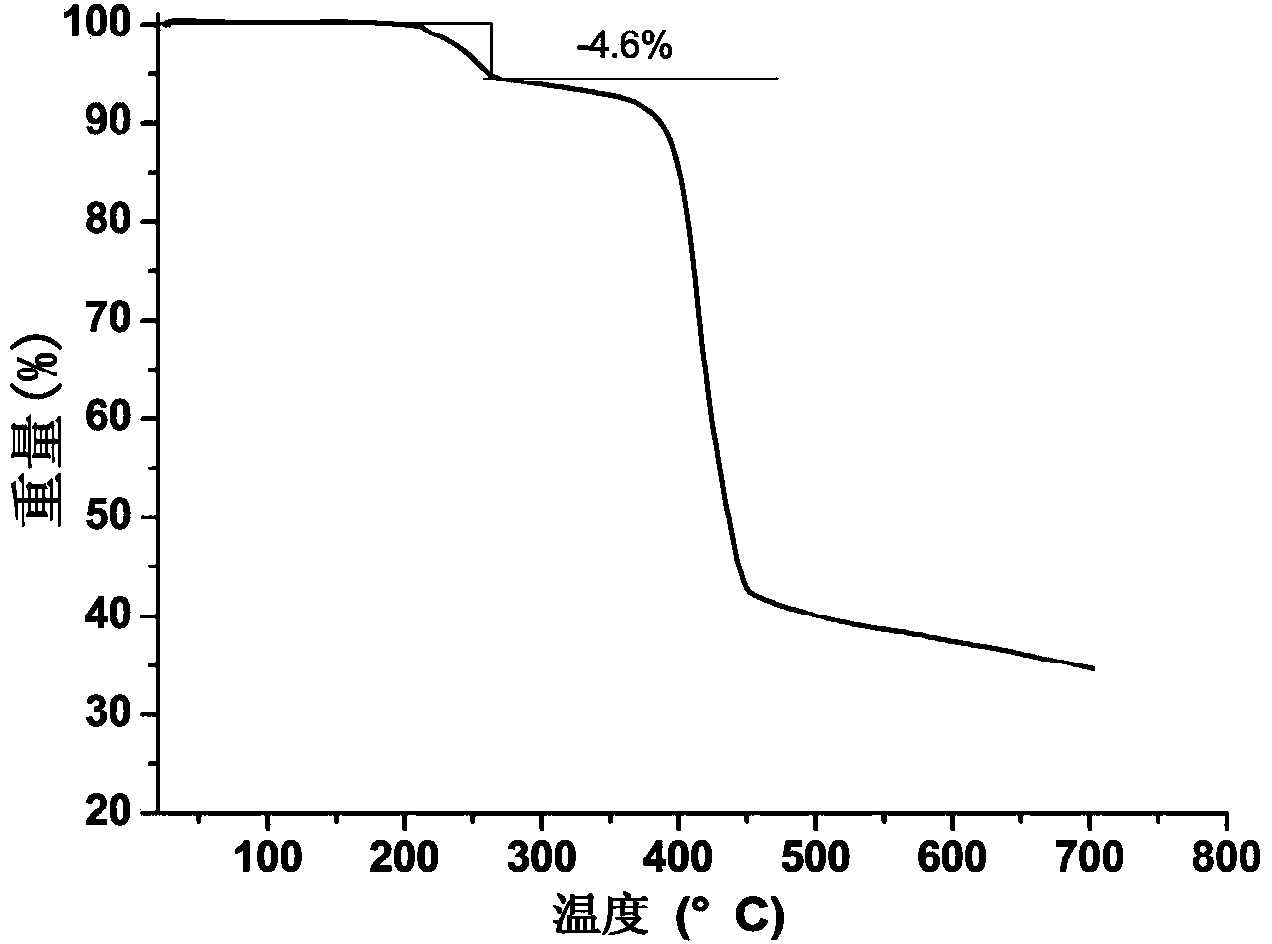

A technology of coordination polymers and polytetrafluoroethylene tubes, which is applied to the magnetism of nickel organic compounds, organic materials/organic magnetic materials, etc., can solve the problems of difficult precision machining, large magnetic loss, and high density, and achieve high heat The effects of stability, high yield and high sample purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

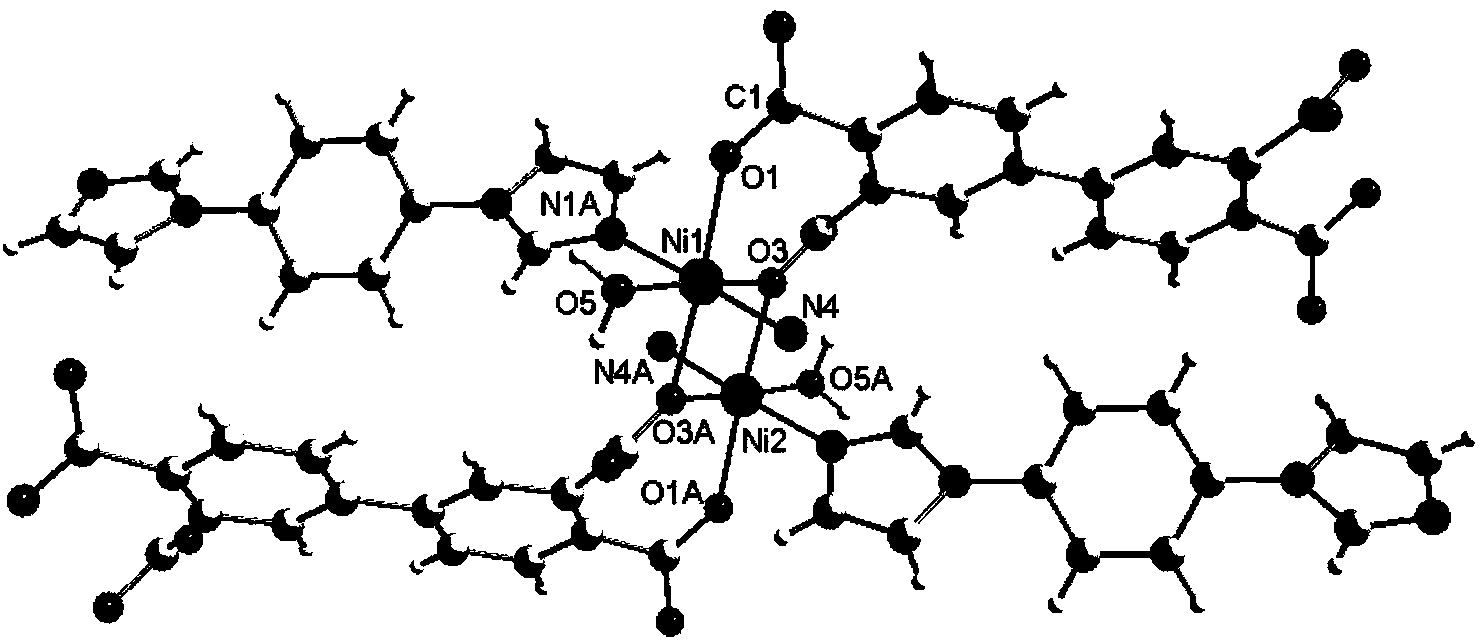

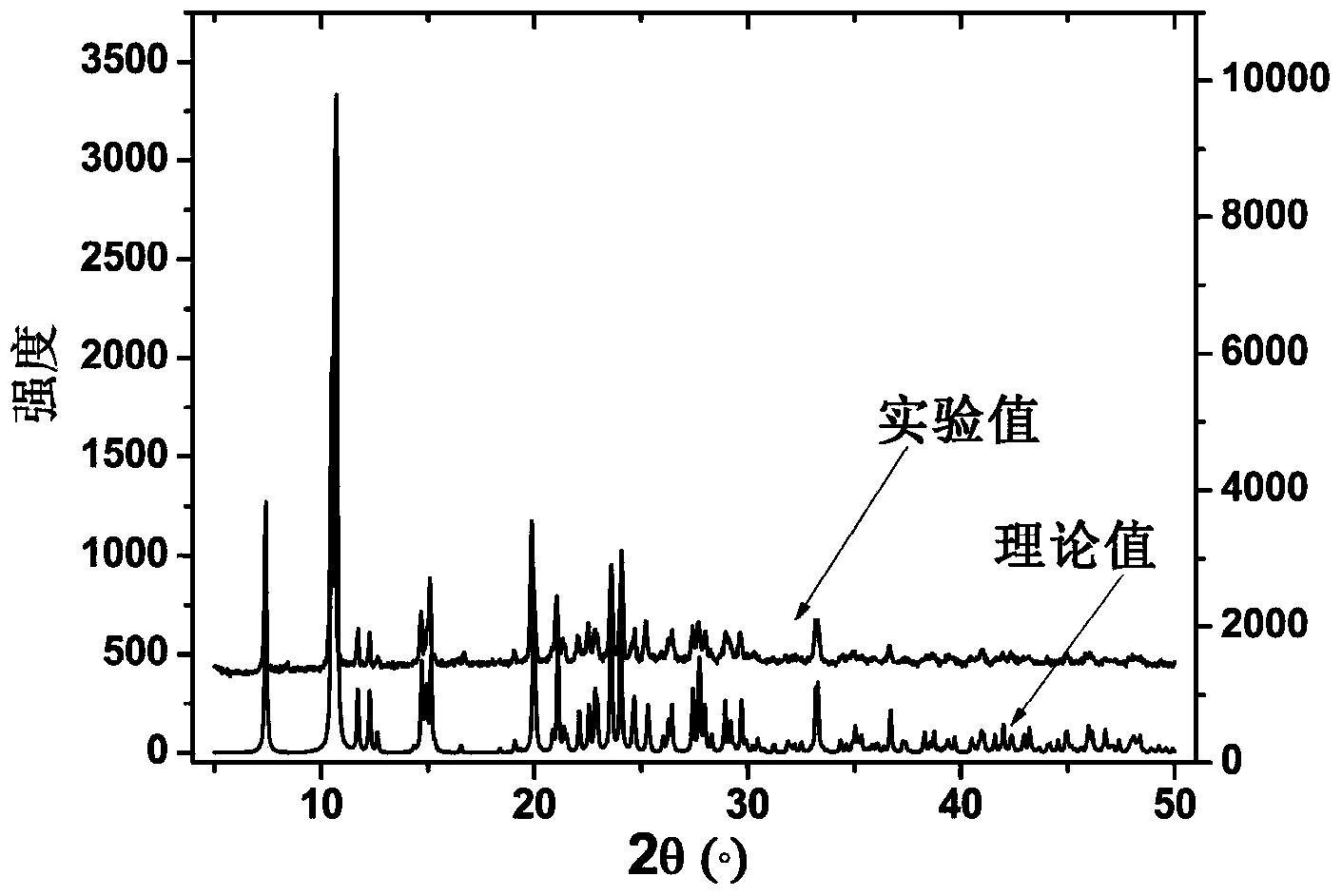

[0018] Example 1. 0.1 mmol H 4 BPTC, 0.2 mmol of 1,4-bib and 0.2 mmol of Ni(NO 3 ) 2 ·6H 2 Mix and dissolve O in 7mL water, adjust the pH to 6.5, place in a 13ml polytetrafluoroethylene tube, stir at room temperature for 30min, seal the polytetrafluoroethylene tube in a stainless steel reaction kettle, crystallize at 160°C for 72h, and cool naturally After reaching room temperature, light blue granular crystals were precipitated, washed with distilled water, and then vacuum pumped to collect the product. The yield was 78.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com