Novel process method for preparing trimethyl borate through continuous reactive distillation

A technology of trimethyl borate and reactive distillation, which is applied in the field of continuous reactive distillation to prepare trimethyl borate, can solve the problems of low primary conversion rate, easy plugging of main equipment, and large loss of boric acid, etc., to reduce overall cost, The effect of saving energy consumption and equipment investment and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

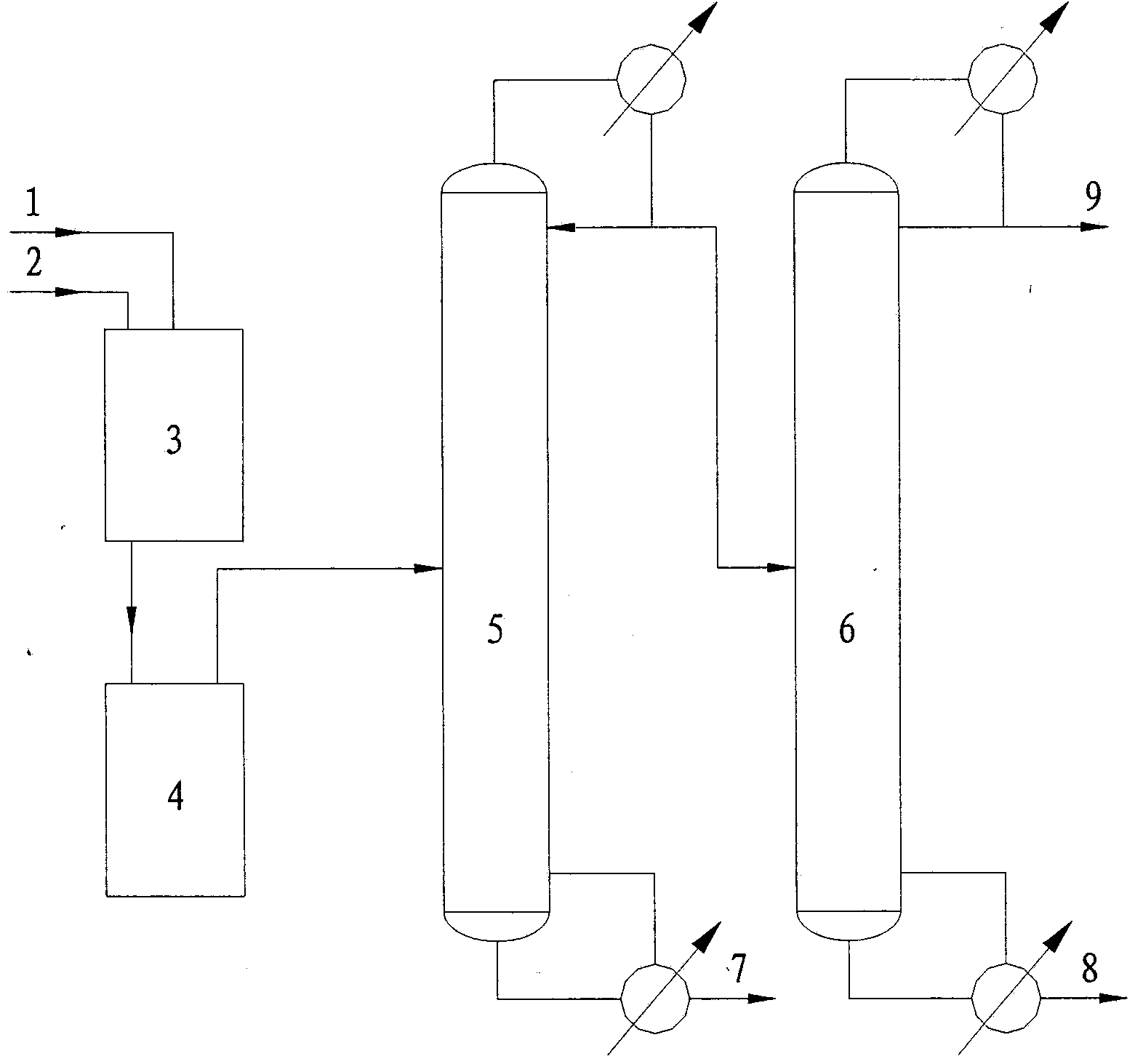

Method used

Image

Examples

Embodiment 1

[0029] Massage methanol and boric acid with a ratio of 10:1, enter the evaporator after preliminary reaction in the reactor, and enter the reactive distillation tower after evaporation. Water is extracted from the bottom of the distillation tower, and the extracted product from the top of the tower enters the azeotropic distillation tower, and the azeotrope of trimethyl borate and methanol is collected from the top of the azeotropic distillation tower. Trimethyl borate can be obtained after the azeotrope separation of trimethyl ester and methanol, and the specific parameters are as follows:

[0030] ⑴. The top temperature of the reactive distillation tower is 61-63°C, and the bottom temperature is 100-101°C

[0031] ⑵. The reflux ratio of the reactive distillation column is controlled to be 3

[0032] (3) The temperature at the top of the azeotropic distillation tower is 53.5-54.5°C, and the temperature at the bottom of the tower is 64-66°C

[0033] ⑷. The reflux ratio of th...

Embodiment 2

[0036] Massage methanol and boric acid with a ratio of 8:1, enter the evaporator after a preliminary reaction in the reactor, enter the reactive distillation tower after evaporation, and extract trimethyl borate and methanol from the top of the reactive distillation tower. Water is extracted from the bottom of the distillation tower, and the extracted product from the top of the tower enters the azeotropic distillation tower, and the azeotrope of trimethyl borate and methanol is collected from the top of the azeotropic distillation tower. Trimethyl borate can be obtained after the azeotrope separation of trimethyl ester and methanol, and the specific parameters are as follows:

[0037] ⑴. The top temperature of the reactive distillation tower is 61-63°C, and the bottom temperature is 100-101°C

[0038] ⑵. The reflux ratio of the reactive distillation column is controlled at 2

[0039] (3) The temperature at the top of the azeotropic distillation tower is 53.5-54.5°C, and the ...

Embodiment 3

[0043] Massage methanol and boric acid with a ratio of 6:1, enter the evaporator after a preliminary reaction in the reactor, and enter the reactive distillation tower after evaporation. Trimethyl borate and methanol are extracted from the top of the reactive distillation tower, and the reaction essence Water is extracted from the bottom of the distillation tower, and the extracted product from the top of the tower enters the azeotropic distillation tower, and the azeotrope of trimethyl borate and methanol is collected from the top of the azeotropic distillation tower. Trimethyl borate can be obtained after the azeotrope separation of trimethyl ester and methanol, and the specific parameters are as follows:

[0044] ⑴. The top temperature of the reactive distillation tower is 61-63°C, and the bottom temperature is 100-101°C

[0045] ⑵. The reflux ratio of the reactive distillation column is controlled at 2

[0046] (3) The temperature at the top of the azeotropic distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com