Clamp for difficult-to-machine material turning surface observing and turning experimental method

A material turning and difficult-to-process technology, applied in the direction of manufacturing tools, turning equipment, turning equipment, etc., can solve the problems of turning surface differences, differences, material waste, etc., and achieve the effect of convenient turning and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

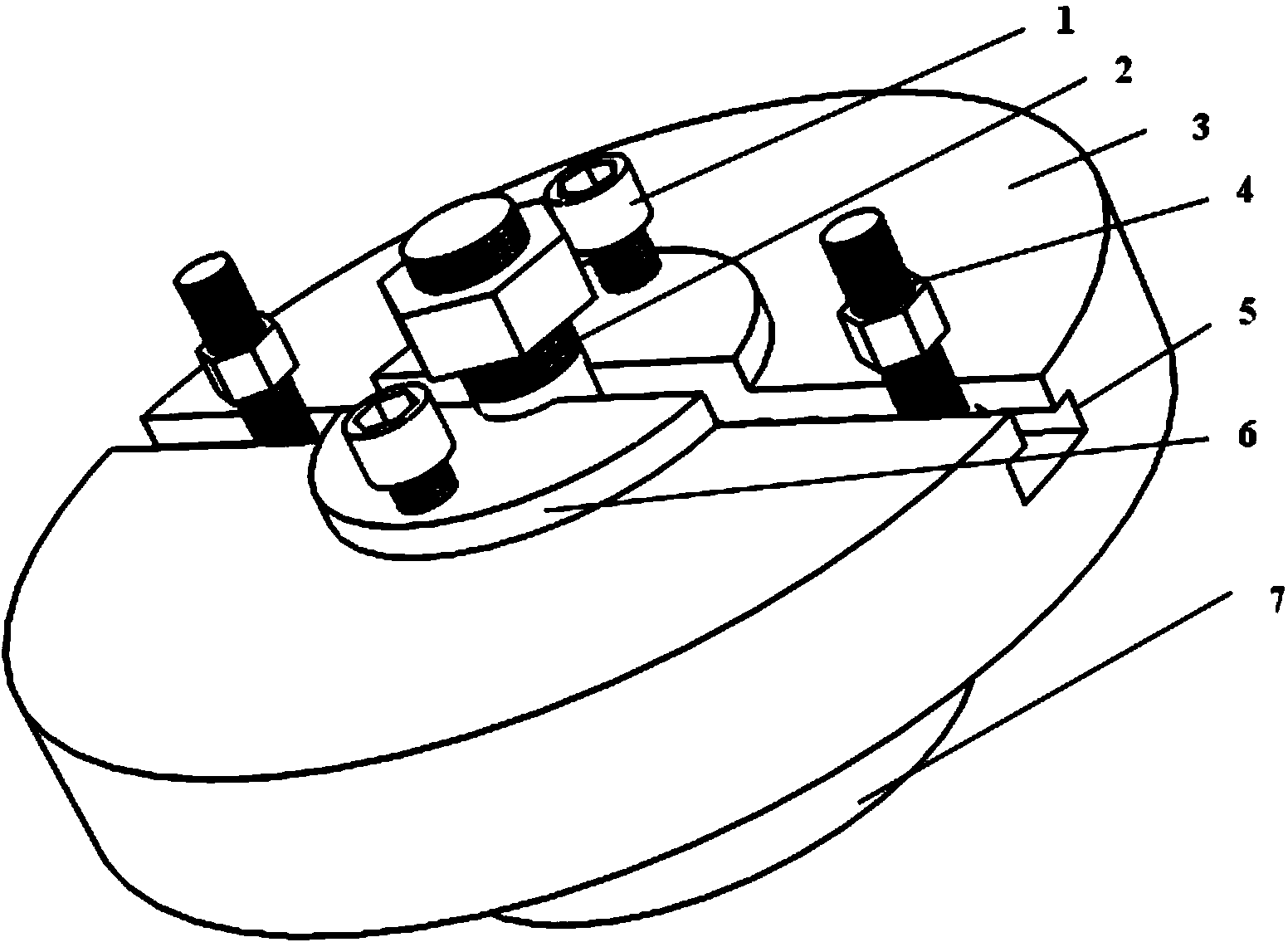

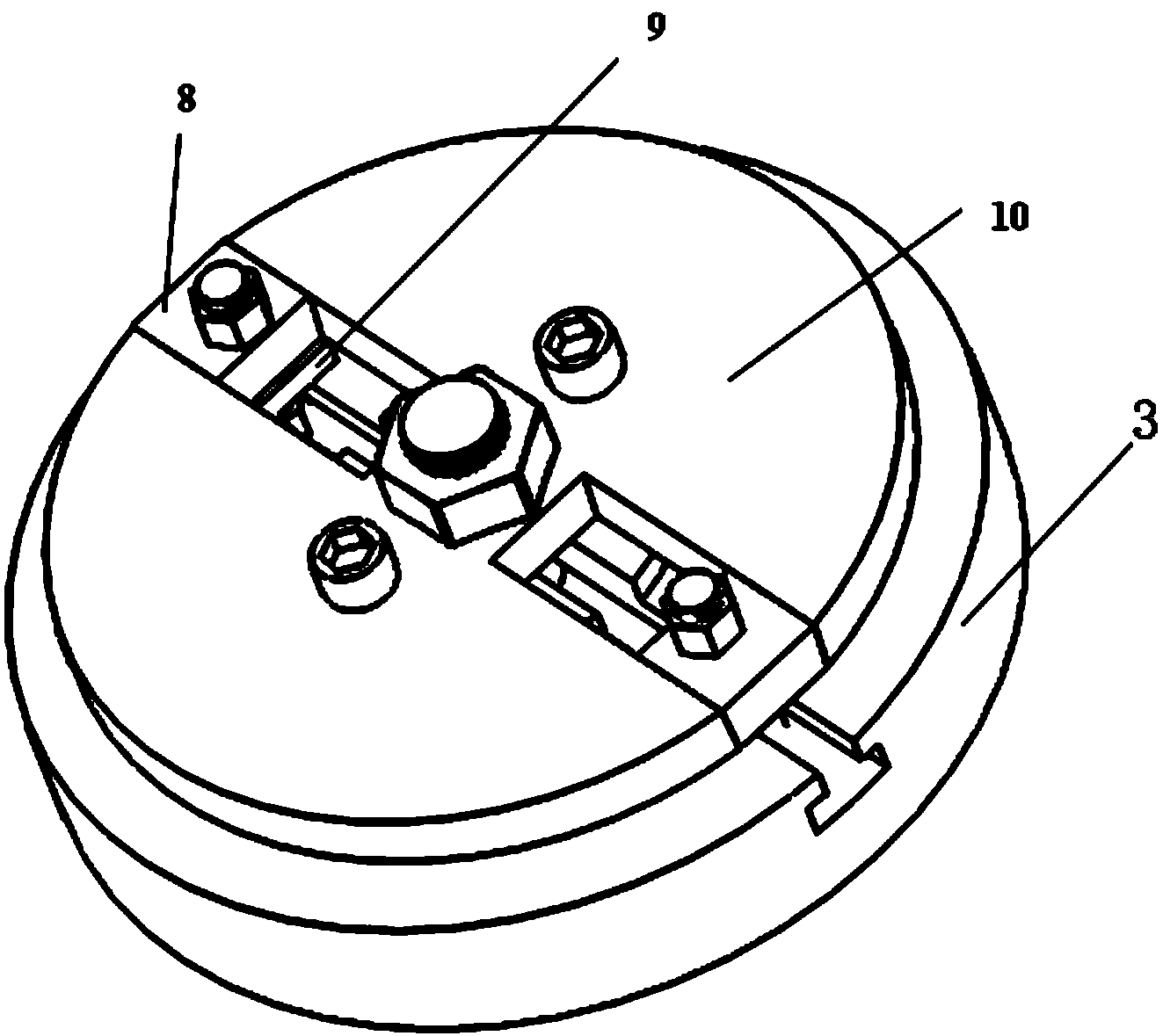

[0022] Such as Figure 1-Figure 3 As shown in Fig. 1 , the fixture is used for observing the turned surface of difficult-to-machine materials. The fixture can realize the convenience of sampling the workpiece, and the sample can be used repeatedly. The clamp includes a mounting plate and a clamping mechanism including a central clamping bolt and a T-bolt.

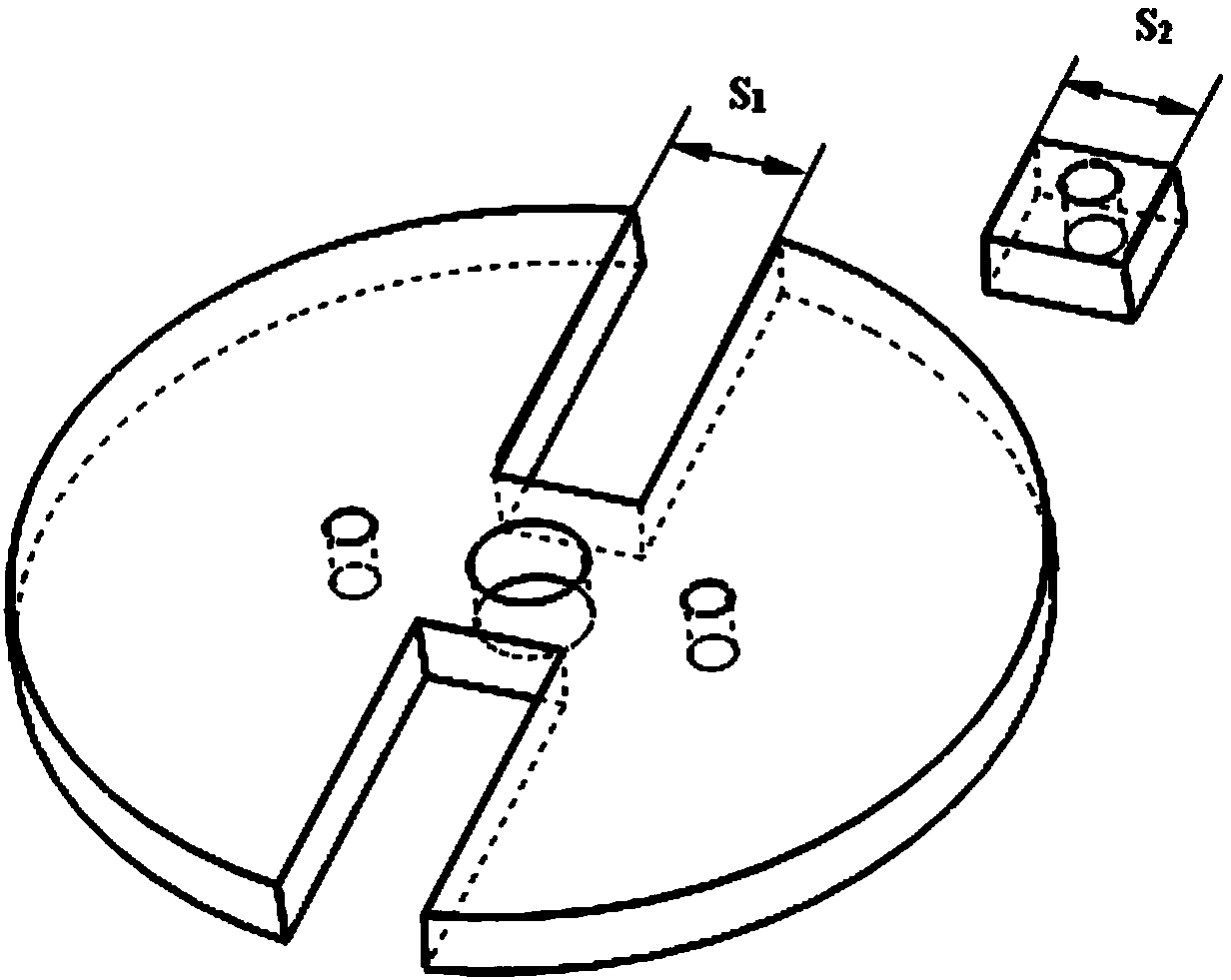

[0023] A T-shaped slot 5 is provided on the diameter of the mounting plate 3 , and a small workpiece is fixed in the T-shaped slot 5 by a T-shaped bolt 4 . The mounting plate 3 is provided with a circular boss 6, and the boss 6 is provided with two threaded holes and matching positioning bolts 1 for the positioning of the circular plate, which is clamped by the central clamping bolt 2; the boss 6 The height is the same as the thickness of the spacer 9 to ensure that the lower surface of the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com