Header for combine harvesters

A technology for combine harvesters and headers, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of difficult maintenance, unfavorable balance between left and right, and high cost, and achieve the effects of easy maintenance, cost reduction and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

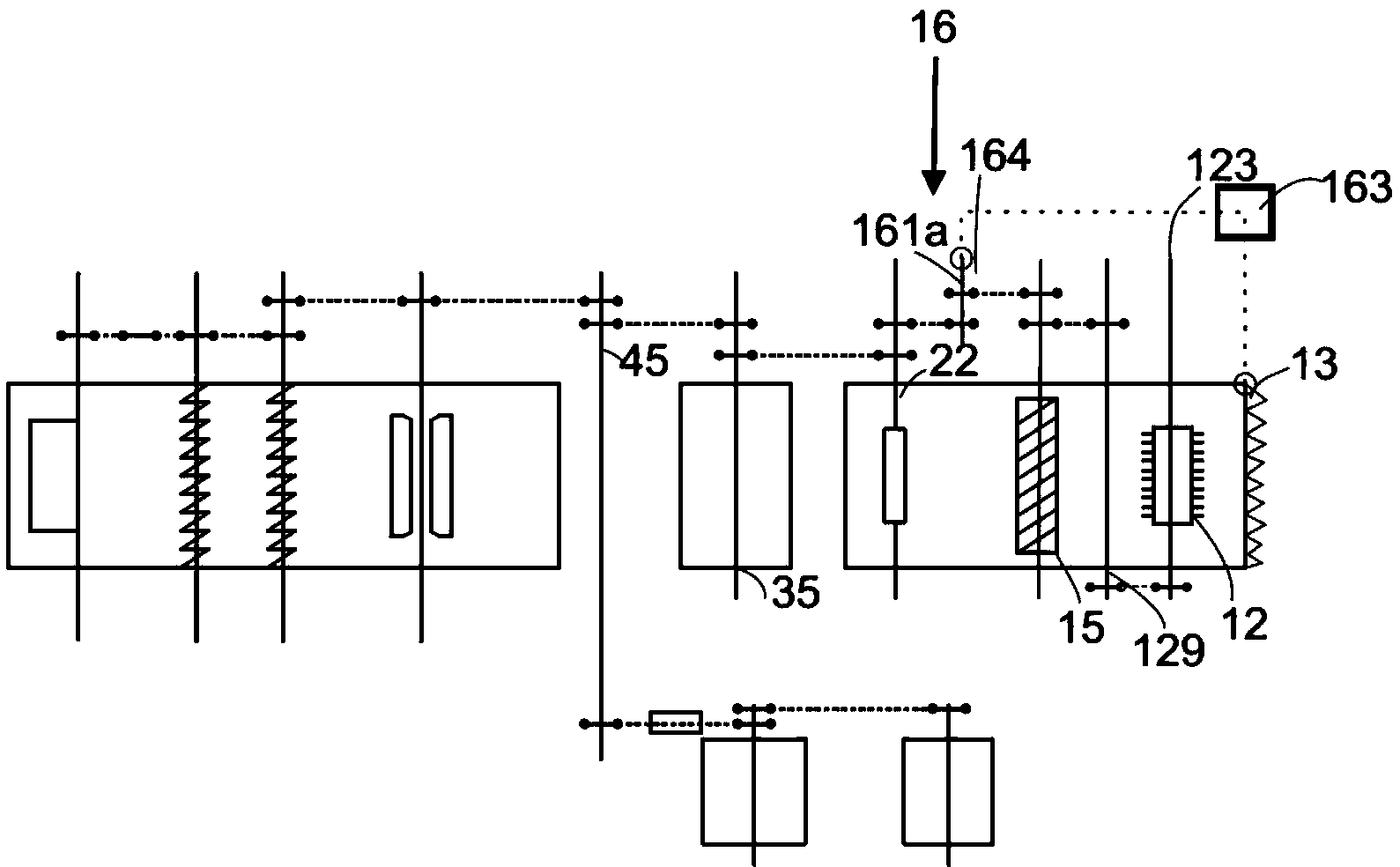

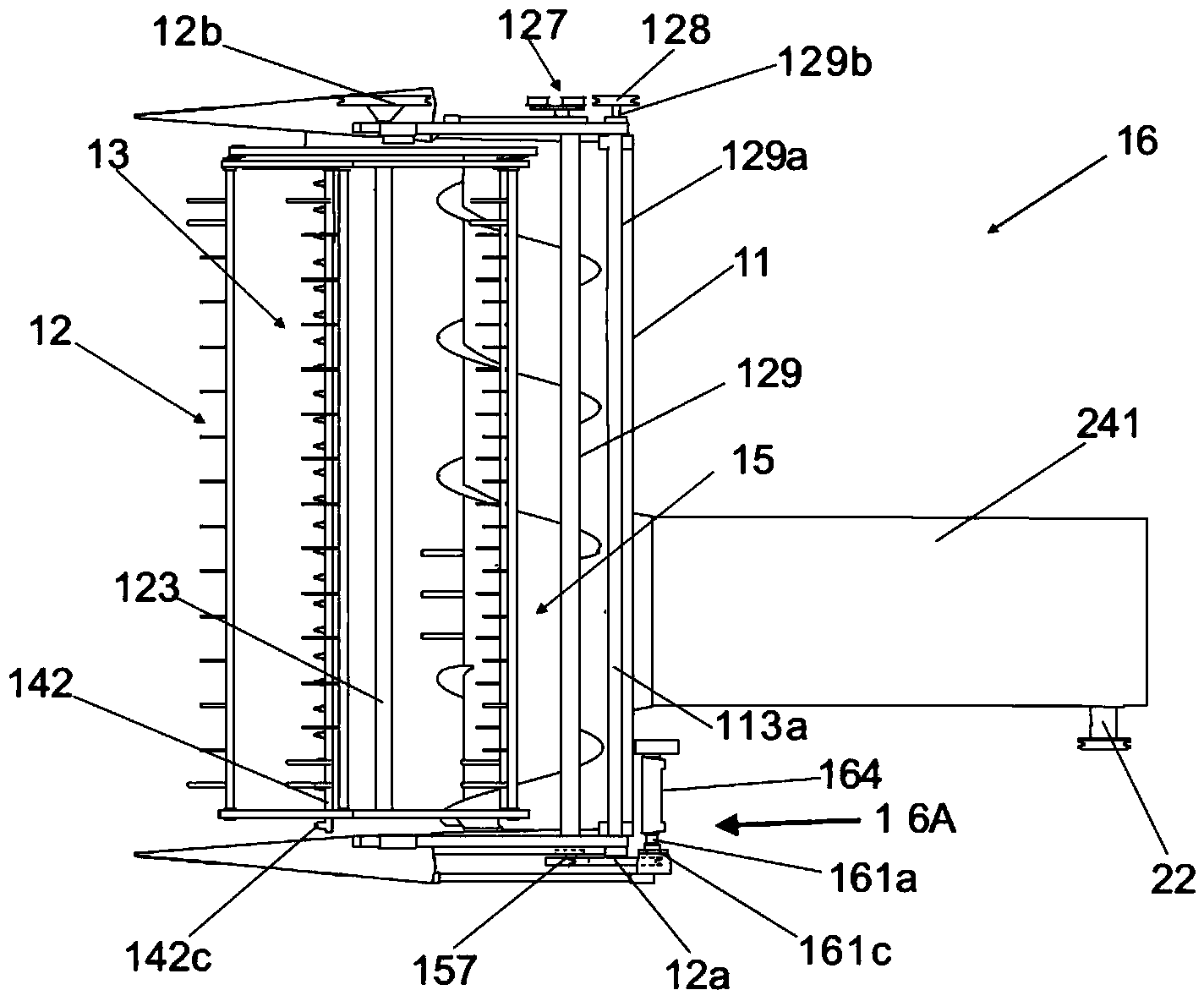

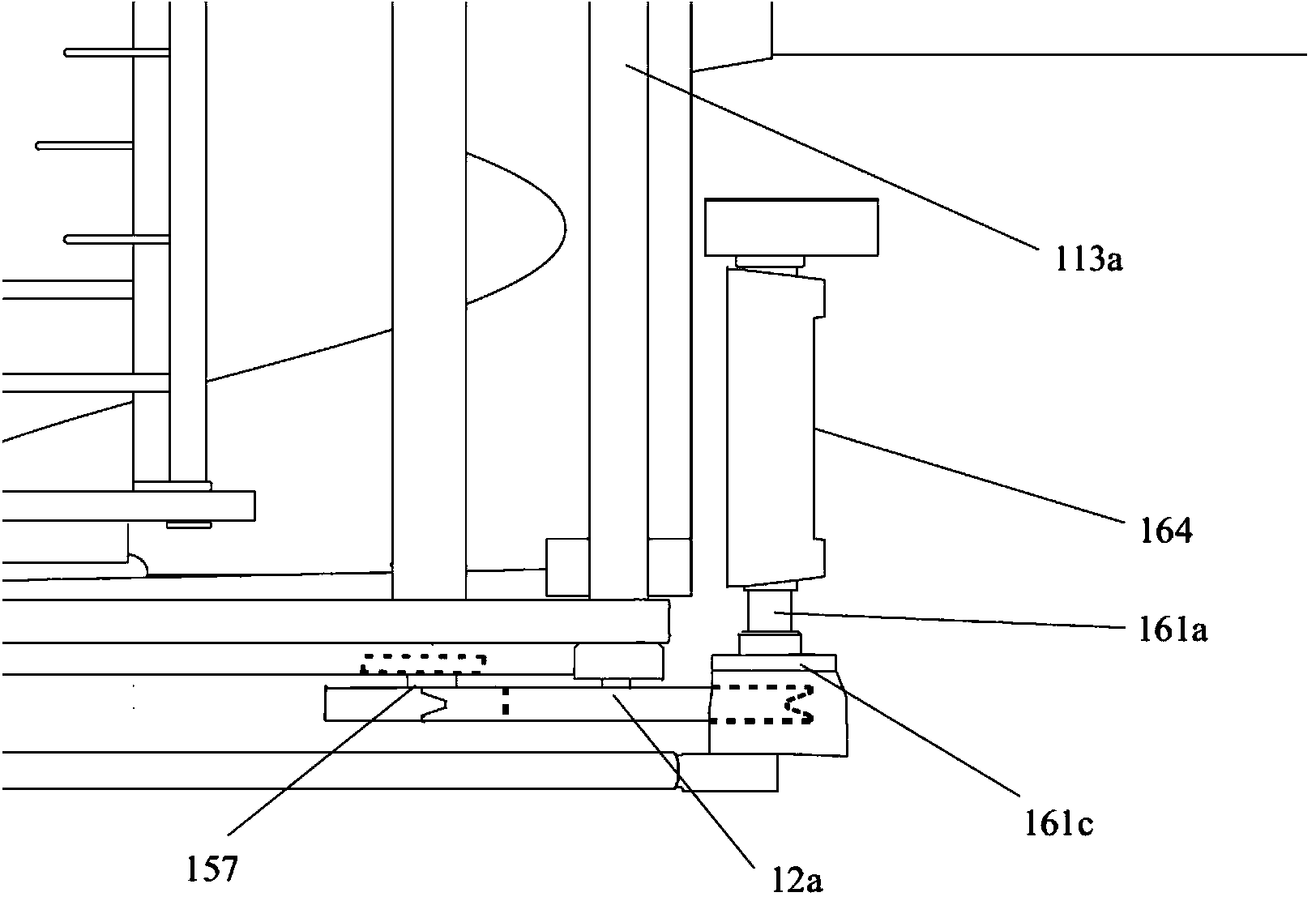

[0022] A kind of combine harvester, the delivery trough 241 on the body, the dustpan-shaped header frame 11 at its front, the cutter 13 at the mouth of the dustpan, the reel 12 at the front and upper side, and the header stirrer at the rear of the dustpan. Dragon 15, straddle the frame and support the reel strut 12A on the rear top of the frame and the header transmission device 16 that transmits the power to the above-mentioned components. This header transmission device is made up of bridge device 164, transitional transmission mechanism 16A, crank link mechanism 163. One end side and the other end side of the intermediate shaft 45 of the driving force of the engine transmit the power forward and backward respectively, and transmit the power forward to the gear box 35. The driving force is transmitted to the bridge transmission shaft 161a, and the bridge transmission shaft 161a transmits the driving force to the header auger 15 and the crank linkage mechanism 163, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com