winder

A technology for winders and bobbins, applied in the field of winders, can solve problems such as toothed belt vibration, adverse effects of traverse consistency of winding stations, etc., and achieve the effect of improving belt guidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

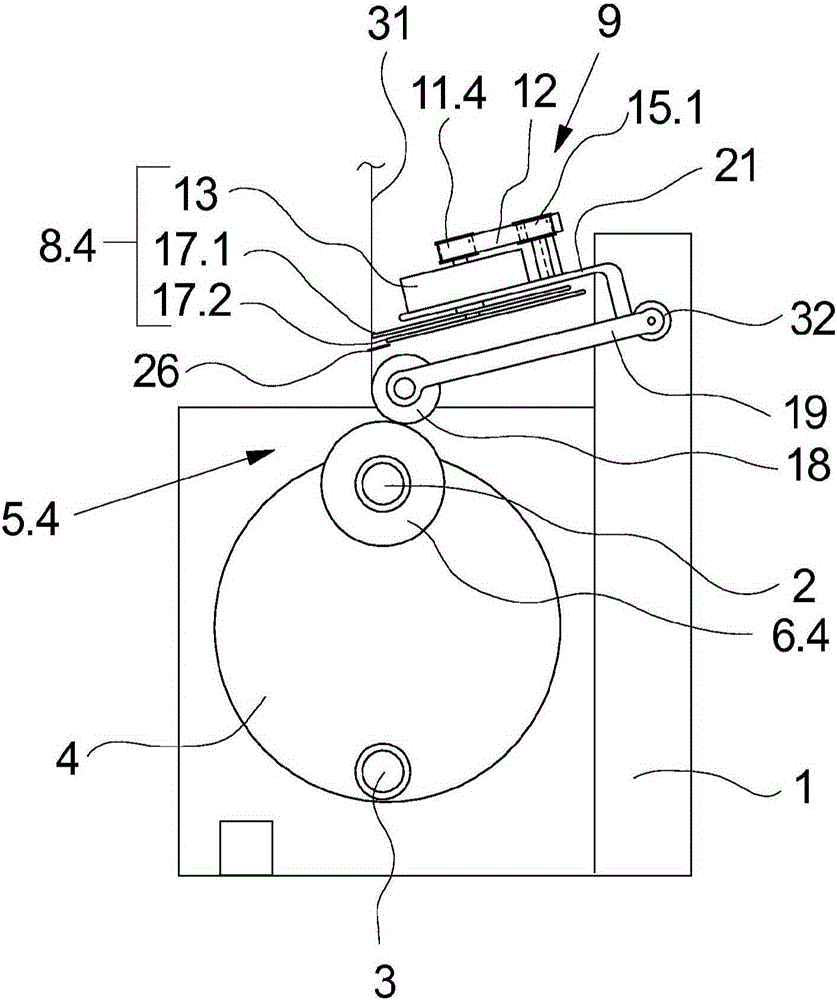

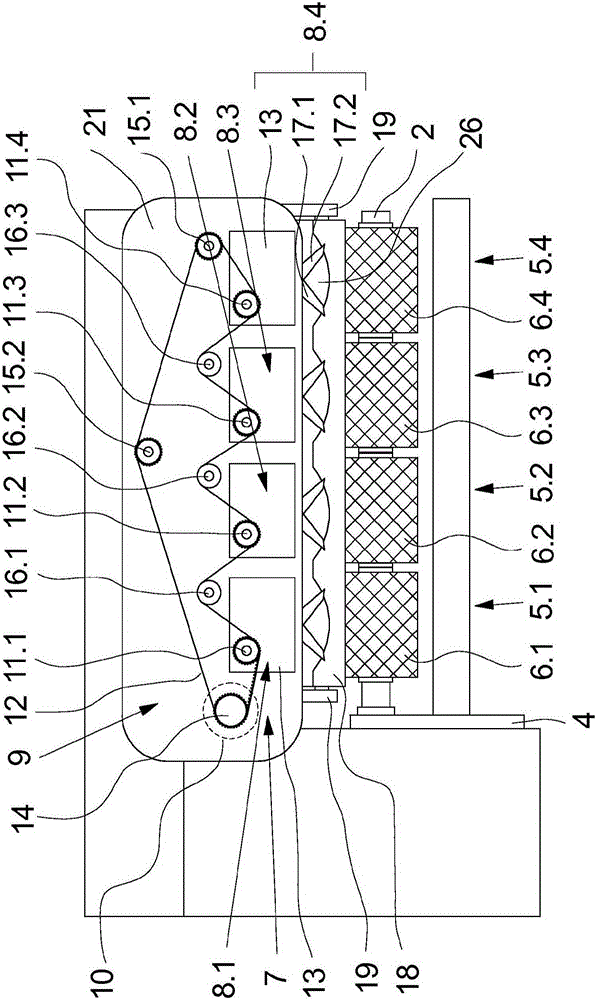

[0024] figure 1 with figure 2 An exemplary embodiment of a winder according to the invention is shown from different perspectives. figure 1 A front view of the exemplary embodiment is schematically shown, figure 2 A top view of the exemplary embodiment is schematically shown. The following description applies to both figures as long as reference is not made to either figure.

[0025] The illustrated exemplary embodiment of the winder according to the invention is typically used in the production of synthetic yarns in a melt spinning plant to wind a set of yarns which are extruded, drawn and Processed into yarn groups and delivered to the winder. In the winder, one of several winding stations is formed for each yarn.

[0026] as available from figure 2 As can be seen from the illustration, the exemplary embodiment has a total of four winding stations 5.1, 5.2, 5.3 and 5.4 for winding the yarn into bobbins 6.1 to 6.4, respectively. For this purpose, the bobbins 6.1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com