Conductive common-mode/differential-mode noise separation method

A technique of differential mode noise, separation method, applied in the direction of noise figure or signal-to-noise ratio measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

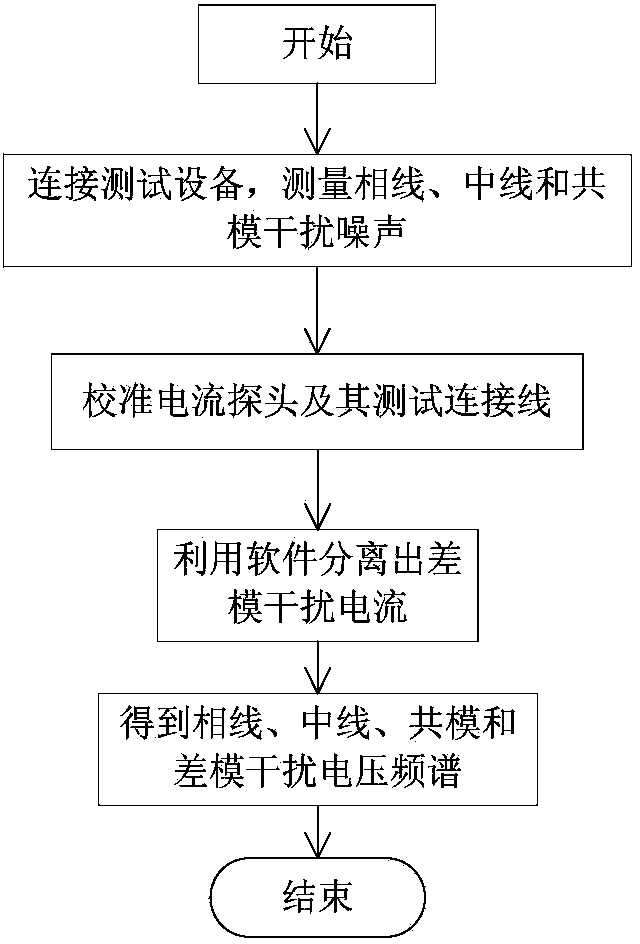

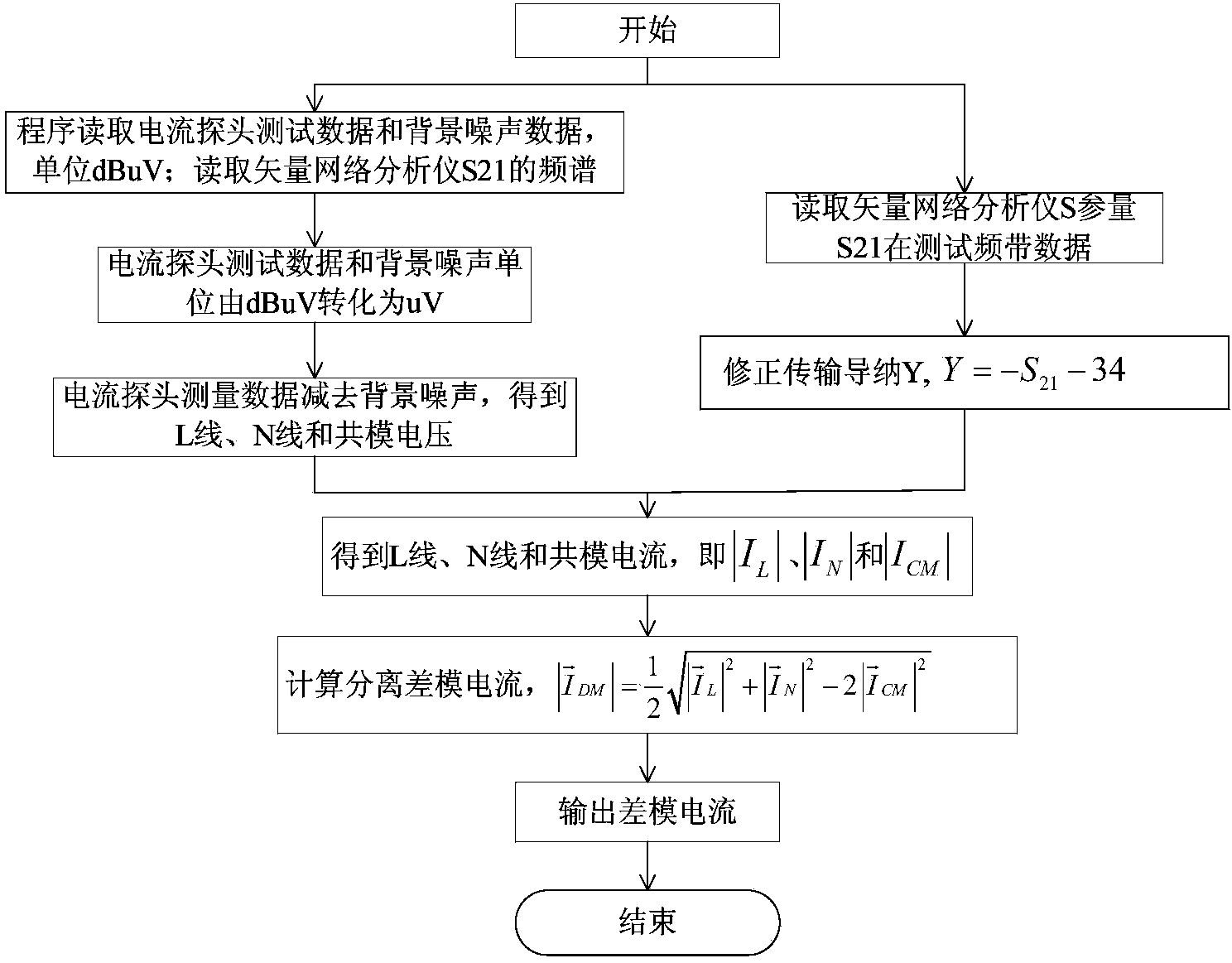

[0050] Below in conjunction with accompanying drawing, the present invention is further described: the present invention's measurement step is as follows:

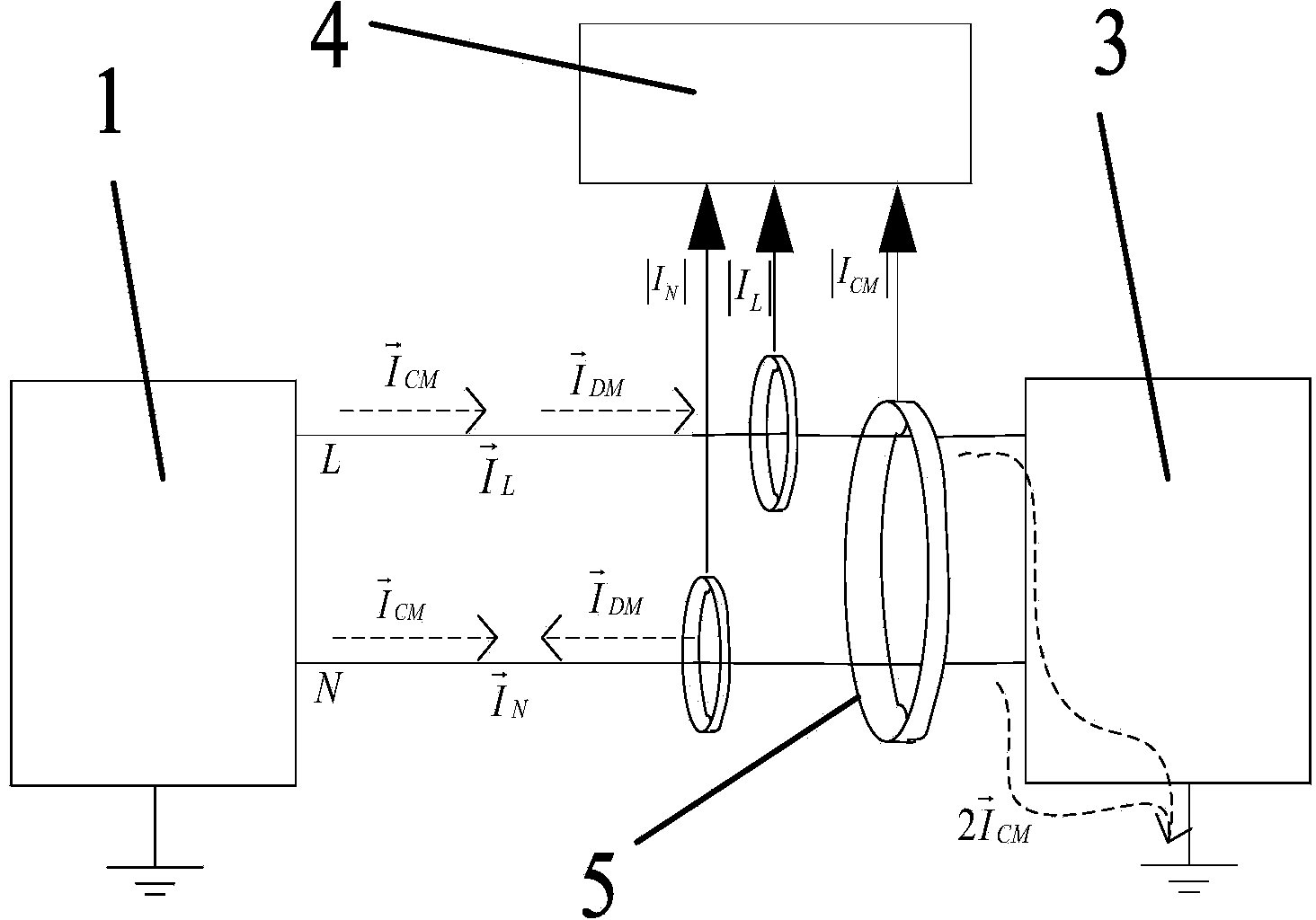

[0051] 1. Prepare to access the measurement environment and connect the measurement equipment:

[0052] The device prepared in this embodiment includes: a commercial switching power supply 3, a current probe 5 (produced by Beijing Daze Company, model ZN23101), a current probe calibration device 6 (produced by Beijing Daze Company, model ZN23302), and a linear impedance stabilization network 1 (produced by Beijing Daze Company, model ZN3770A), one spectrum analyzer 4 (produced by American Agilent Company, model N9000A), one set of vector network analyzer 2 (produced by American Agilent Company, model E5071C), standard calibration parts ( American Agilent Company, model 85032E), a set of coaxial cables with a characteristic impedance of 50Ω, and a computer.

[0053] The linear impedance stabilization network 1 is used to is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com