Composite phase-change cold-accumulation material

A composite material and phase-change cold storage technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reduced cool feeling of dodecanol, difficult to control the shape of the seat cushion, no comfort, etc., and achieves convenient and easy-to-obtain raw materials. , The effect of stable chemical properties and difficult to store containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097]The phase change cold storage composite material is prepared by the following method:

[0098] At room temperature, weigh dodecyl alcohol, surfactant and water according to the above weight ratio, place the weighed surfactant in a container, add weighed water to it, and batch by batch under stirring Add or drop dodecanol, continue to stir or ultrasonically oscillate to fully mix the above-mentioned components, and prepare a microemulsion phase-change cold storage composite material.

[0099] In the phase change cold storage composite material provided by the present invention, in the preparation process, it is necessary to add dodecanol to the mixture of water and surfactant, if it is added at one time, phase separation will occur and it will also fail when the stirring time is prolonged A homogeneous phase-change cold-storage composite material cannot be prepared; however, when dodecyl alcohol is added or dropped in batches under stirring or ultrasonic conditions, the p...

Embodiment 1

[0140] At normal temperature, weigh 6.00g of dodecanol, 1.00g of Tween-80, and 2.58g of water, place the weighed Tween-80 in a beaker, add the weighed water to it, and stir Add the weighed lauryl alcohol dropwise under the condition of stirring, add the weighed lauryl alcohol in 6 times under the condition of stirring, add 1g each time, stir at intervals of 30s, so that the above-mentioned components are fully mixed evenly, and prepared into micro Emulsion phase change cold storage composite material.

[0141] (1) DSC analysis is carried out to the phase change cold storage composite material that makes, the procedure is:

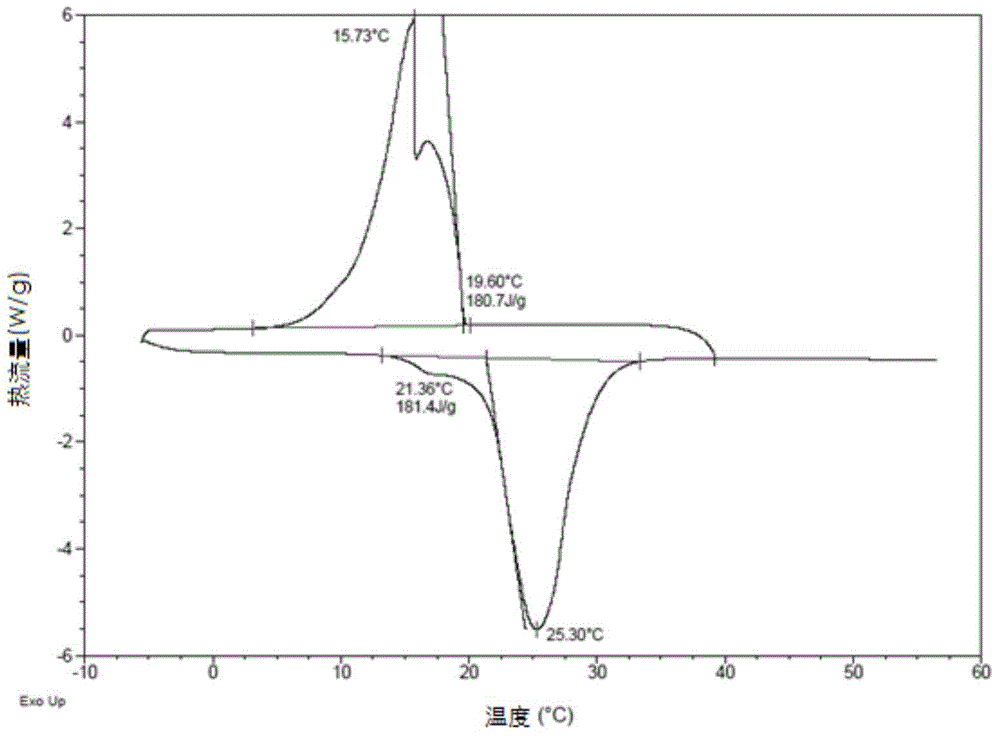

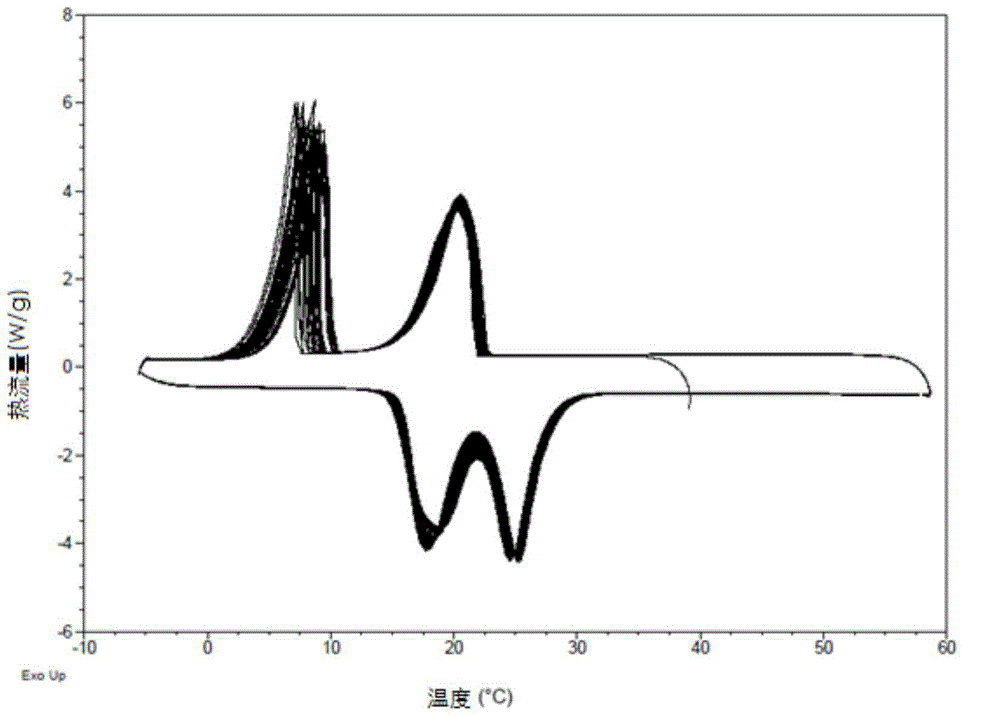

[0142]1) Decrease to -5°C at 10°C / min; 2) Stabilize at -5°C for 5 minutes; 3) Rise to 60°C at 10°C / min, cycle 50 times, the results are as follows figure 2 shown. Depend on figure 2 It can be clearly seen that the ability of the phase-change cold storage composite material provided by the present invention does not show an obvious downward trend during...

Embodiment 2

[0146] At room temperature, weigh 6.00g of dodecanol, 1.00g of Tween-80, and 4.55g of glycerin, place the weighed Tween-80 in a beaker, add the weighed glycerol at one time, fully After stirring to fully dissolve Tween-80, add the weighed lauryl alcohol in 6 times under the condition of stirring, add 1g each time, stir for 30s at intervals, continue stirring to fully mix the above components evenly, and prepare micro Emulsion phase change cold storage composite material.

[0147] (1) DSC analysis is carried out to the obtained phase change cold storage composite material, the procedure is:

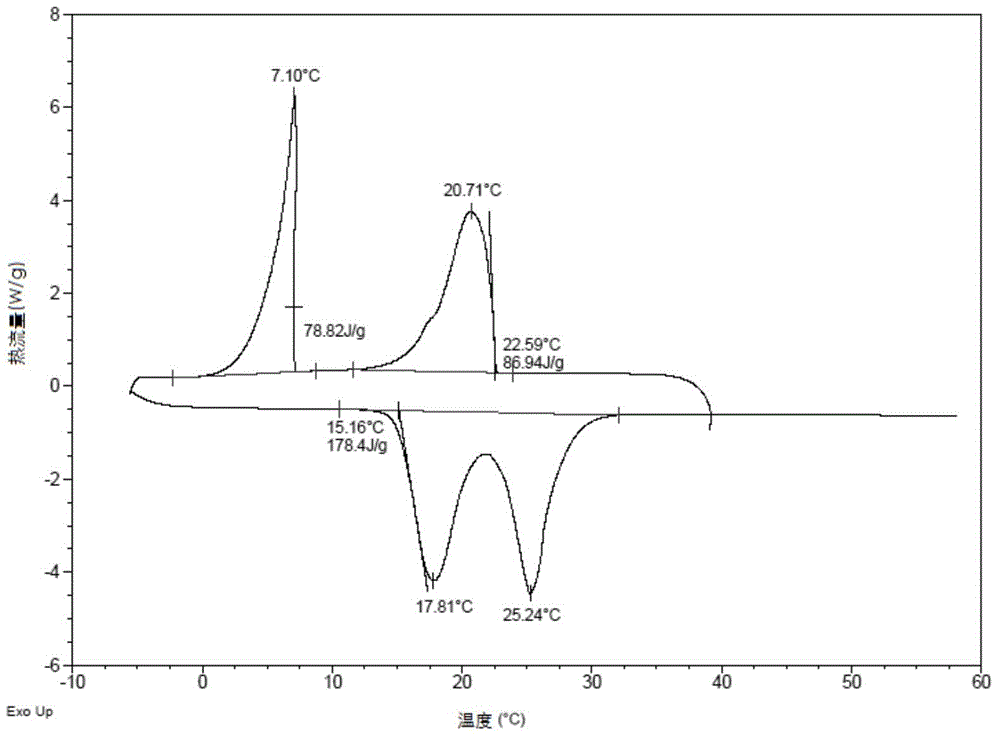

[0148] 1) Decrease to -5°C at 10°C / min; 2) Stabilize at -5°C for 5 minutes; 3) Raise to 60°C at 10°C / min, the results are as follows Figure 6 Shown: the heat of phase transition is 163.1J / g, and the melting point is 23.28°C.

[0149] (2) Structural characterization of the prepared phase change cold storage composite material by infrared spectroscopy, the results are as follows Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com