Tablet outlet device of tablet press capable of achieving clean powder-free tablet outputting and using method thereof

A tableting machine and cleaning technology, applied in the field of tableting machines, can solve the problems that the tableting method does not meet the requirements of energy saving, clean production, the occupational health injury and damage of operators, etc., so as to eliminate the factors of tablet damage and eliminate the Occupational injuries, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

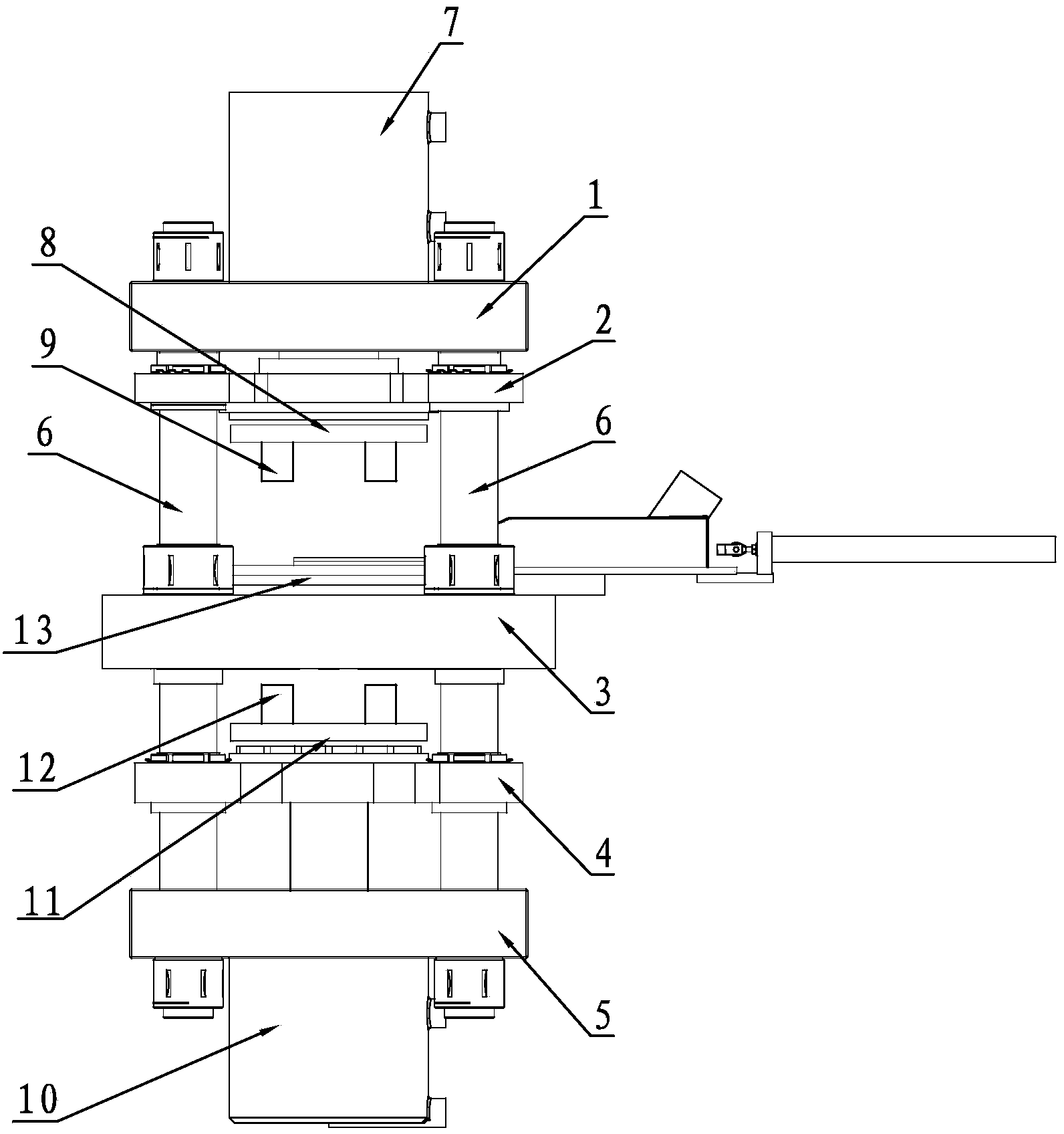

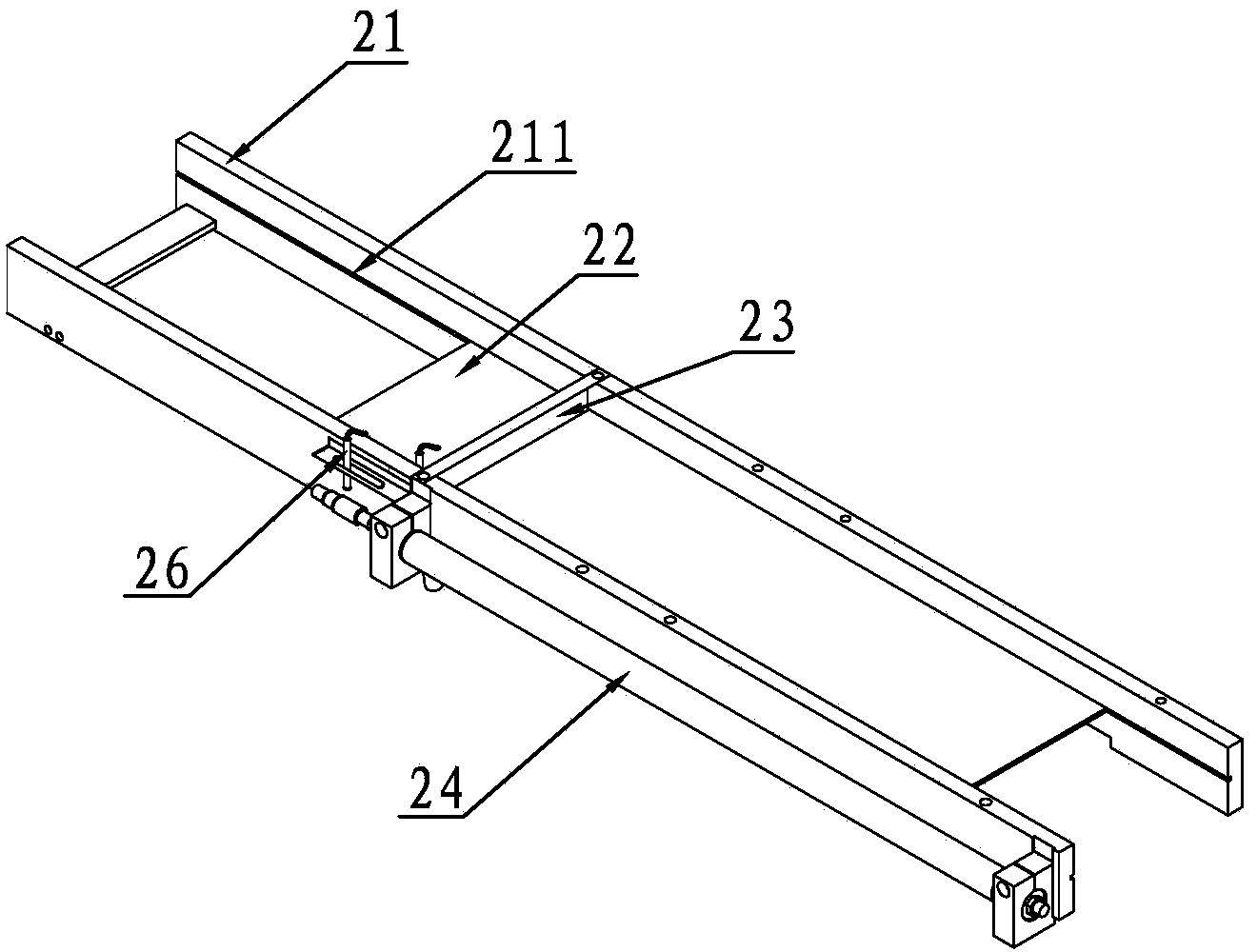

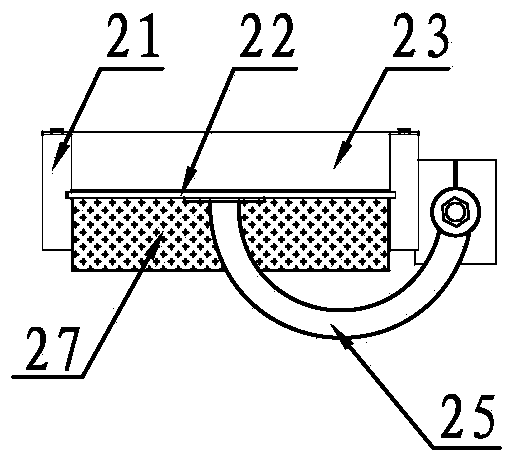

[0031] Embodiment 1: A tablet machine free from sticky powder cleaning tablet discharge device, such as Figure 2 ~ Figure 6As shown, it includes two guide rail bodies 21 arranged in parallel, a moving joint plate 22, a bracket plate 23, a reciprocating linear motion part 24, a connecting rod 25, a limit switch 26 and a cleaning brush 27, and two guide rail bodies 21 Horizontally fixedly installed on the middle fixed plate 3, the distance between the two guide rail bodies 21 is greater than the width of the tablet cavity template 13, and a guide groove 211 with a rectangular cross-sectional shape is provided on the inner surface of the two guide rail bodies 21, The movable contact plate 22 can be freely slidably inserted in the guide groove 211, and there is clearance fit between the movable contact plate 22 and the guide groove 211, and the retainer plate 23 is fixedly mounted on the upper end surfaces of the two guide rail bodies 21, and 100 millimeters apart from the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com