Workpiece automatic clamping device

An automatic clamping and workpiece technology, which is applied in the direction of clamping devices, positioning devices, metal processing machinery parts, etc., can solve the problems of different processing reference positions, reduce the processing efficiency of drilling machines, and troublesome operation, so as to improve processing efficiency and shorten processing time. Prep time, easy operation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described with reference to the drawings and specific embodiments.

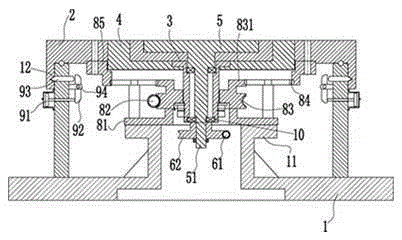

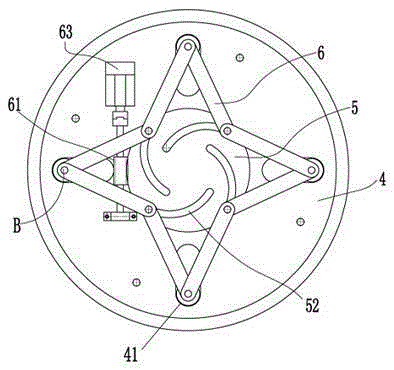

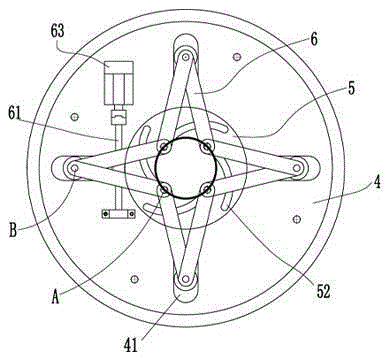

[0016] reference figure 1 and image 3 , This embodiment discloses an automatic workpiece clamping device, including a connecting base 1, a worktable turntable 2, a spindle sleeve 3, an automatic centering flower disk 4, a parabolic flower disk 5, 8 connecting rods 6 and 4 positioning claws (in the figure) (Not shown), the worktable turntable 2 is rotatably arranged above the connecting base 1 through a worktable rotating mechanism to locate the required processing position. The outer disk must be locked when processing parts, and the spindle The sleeve 3 is fixed under the middle of the worktable turntable 2. The parabolic faceplate 5 is rotatably arranged on the worktable turntable 2. A faceplate drive shaft 51 is connected below the parabolic faceplate 5, and the faceplate drive shaft 51 extends The lower part of the main shaft sleeve 3 is in transmission conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com