Preparation method for photoluminescence core-shell nano-copper cluster

A technology of nano-copper clusters and photoluminescence, which is applied in nanotechnology, luminescent materials, chemical instruments and methods, and can solve the problems of no reports on nano-copper clusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

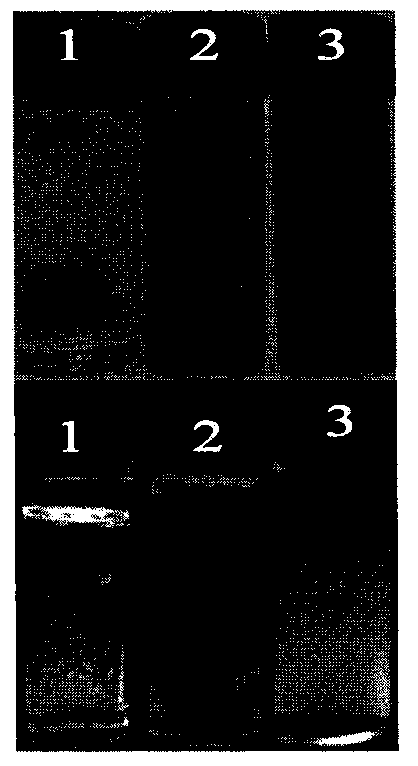

Embodiment 1

[0023] a. Add water to thioglycolic acid at a temperature of 20°C to prepare an acidic solution with pH=2.3;

[0024] b. Add the thioglycolic acid acidic solution prepared in step a into 50ml of copper acetate: hexadecyltrimethylammonium bromide = 1:1 in molar ratio respectively, and perform ultrasonic treatment for 5 minutes, at a temperature of 20°C, and disperse Uniformly, a mixed solution is obtained;

[0025] C, drip hydrazine hydrate in the acidic mixed solution that step b obtains, the add-on of hydrazine hydrate is copper acetate in molar ratio: hexadecyltrimethylammonium bromide: hydrazine hydrate=1:1:1, stand 1 Within 2 hours, a photoluminescence core-shell structure nano-copper cluster material containing a core of 5 copper atoms and a shell of a copper-mercaptoacetic acid complex can be obtained.

Embodiment 2

[0027] a. Add water to thioglycolic acid at a temperature of 25°C to prepare an acidic solution with pH=3;

[0028] b. Add the thioglycolic acid acidic solution configured in step a into 50 ml of copper chloride in molar ratio: dodecyltrimethylammonium bromide = 1: 5, and perform ultrasonic treatment for 8 minutes at a temperature of 20°C. Disperse evenly to obtain a mixed solution;

[0029] C, drip hydrazine hydrate in the acidic mixed solution that step b obtains, the add-on of hydrazine hydrate is copper chloride in molar ratio: dodecyltrimethylammonium bromide: hydrazine hydrate=1:5:10, stand still In one hour, a photoluminescence core-shell structure nano-copper cluster material containing a core of 5 copper atoms and a shell of a copper-mercaptoacetic acid complex can be obtained.

Embodiment 3

[0031] a. Add water to thioglycolic acid at a temperature of 30°C to prepare an acidic solution with pH=4;

[0032] b. Add the thioglycolic acid acidic solution prepared in step a into 50ml of copper sulfate: trioctyl ammonium chloride = 1:10 in molar ratio respectively, carry out ultrasonic treatment, ultrasonic time is 10 minutes, temperature is 20°C, disperse evenly, and mix liquid;

[0033] c. Add hydrazine hydrate dropwise to the acidic mixed solution obtained in step b. The amount of hydrazine hydrate is based on the molar ratio of copper sulfate: trioctyl ammonium chloride: hydrazine hydrate = 1:5:15, and leave it for 2 hours. A photoluminescent core-shell structure nano-copper cluster material containing a core of 5 copper atoms and a shell of a copper-mercaptoacetic acid complex is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com