Method for contactlessly breaking polycrystalline silicon

A polysilicon, non-contact technology, applied in the direction of grain processing, etc., can solve the problems of increasing steps, low overall efficiency of crushing, and increasing the risk of polysilicon rod contamination, so as to achieve the effect of improving efficiency and reducing the risk of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

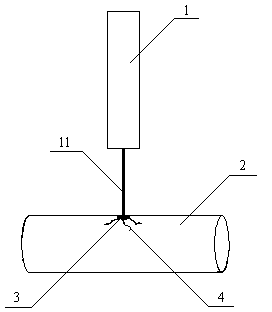

[0035] Such as figure 1 As shown, the method for non-contact laser crushing of polycrystalline silicon rods or polycrystalline silicon blocks of the present invention can be described in more detail. A laser beam 11 is generated by a laser 1 . When the laser beam 11 irradiates the local area 3 of the polycrystalline silicon rod or polycrystalline silicon block 2 , the energy of the laser beam 11 is absorbed by the local area 3 of the polycrystalline silicon rod or polycrystalline silicon block 2 . After the local region 3 of the polycrystalline silicon rod or polycrystalline silicon block 2 absorbs the energy of the laser beam 11, the temperature of the local region 3 of the polycrystalline silicon rod or polycrystalline silicon block 2 rises rapidly. As the temperature of the local region 3 of the polycrystalline silicon rod or polycrystalline silicon block 2 increases, the density of the local region 3 of the polycrystalline silicon rod or polycrystalline silicon block 2 de...

Embodiment 2

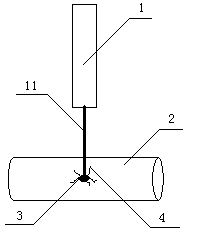

[0040] Lasers 1 with longer wavelengths can also be used when carrying out the method of the invention for non-contact fragmentation of polycrystalline silicon rods or polycrystalline silicon blocks by laser. exist figure 2 In the embodiment, the laser beam is an infrared laser beam 11, that is, a laser beam with a wavelength of 1064 nanometers. When using an infrared laser, since the polycrystalline silicon rod or polycrystalline silicon block 2 has a small absorption coefficient for infrared light, the focus of the laser beam must be adjusted to the internal point of the polycrystalline silicon rod or polycrystalline silicon block 2, that is, the local area 3 . After the point of the polycrystalline silicon rod or the polycrystalline silicon block 2, that is, the local area 3, is irradiated by the infrared laser beam 11, the temperature of the point of the polycrystalline silicon rod or the polycrystalline silicon block 2, that is, the local area 3, rises rapidly, and a hug...

Embodiment 3

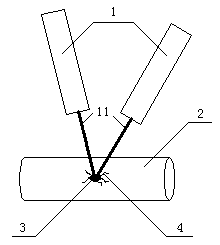

[0042] In other applications of the method for non-contact breaking of polycrystalline silicon rods or polycrystalline silicon blocks by laser of the present invention, multiple lasers can be used to achieve the purpose of breaking polycrystalline silicon rods or polycrystalline silicon blocks 2 . image 3 An embodiment of the invention using 2 lasers 1 for fragmenting polysilicon rods or blocks 2 is shown. In this embodiment, two infrared lasers 1 each generate an infrared laser beam 11 . Both infrared laser beams 11 are focused on a point, ie a local area 3 , of the polysilicon rod or block 2 . After the point of the polycrystalline silicon rod or the polycrystalline silicon block 2, that is, the local area 3, is irradiated by two infrared laser beams 11, the temperature of the point of the polycrystalline silicon rod or the polycrystalline silicon block 2, that is, the local area 3, rises rapidly. A huge temperature gradient is formed, and this huge temperature gradient cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com