High-quality minced nemipterus hexodon product and preparation method thereof

A technology for the surimi and surimi products, which is applied in the field of high-quality surimi products and their preparation, can solve the problem that there are few researches on the optimization process for the preparation of surimi and it is difficult to obtain the surimi. The problems of limited research on products and gel properties can avoid gel deterioration, large number of products, and easy inactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 The assay method of formula and technology research experiment related index of the present invention

[0065] 1. Determination of gel strength: refer to the method of Balange et al (2009) to determine the gel strength.

[0066] For the gel strength test, the probe model is P / 5, and the test mode is compression force mode. The compression deformation rate is 60mm / min, and the breaking strength (Breaking Force) and the depression depth (Deformation) are obtained respectively.

[0067] Gel Strength = Breaking Strength × Depression Depth.

[0068] 2. Determination of all texture properties: refer to the method of Maqsood et al (2012) to determine the hardness (hardness), elasticity (springiness), cohesiveness (cohesiveness) and chewiness (chewiness) of the sample. The probe model selected for the texture characteristic test is P / 50, and the test mode is TPA. The specific test parameters are: pressing speed 5mm / s, compression deformation rate 50%, surface in...

Embodiment 2

[0095] Example 2 Determination of ultra-high pressure in the process of preparing high-quality gold wire surimi products according to the present invention

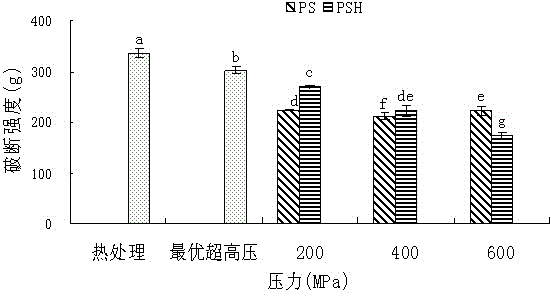

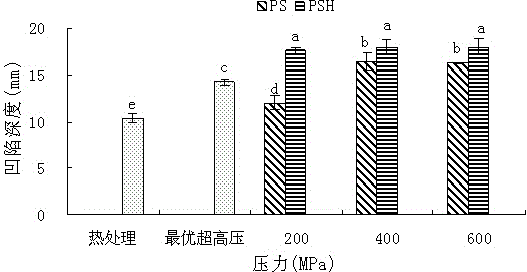

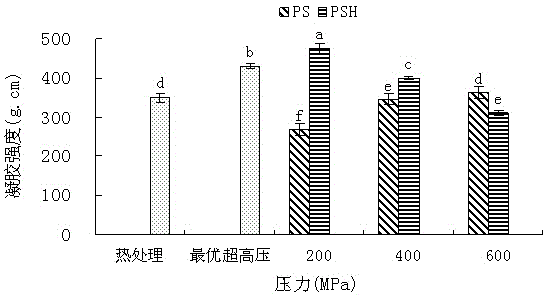

[0096] 1. The effect of different pressure and heat treatment on the gel strength of surimi

[0097] The effects of different pressures combined with heat treatment on the breaking strength, depression depth and gel strength of surimi gel after holding for 30 minutes are shown in the attached figure 1 , 2 and 3. After heat treatment (stand still at 40°C for 30min, then heat at 90°C for 20min), the surimi gel had a breaking strength of 336.083g, a depression depth of 12.008mm, and a gel strength of 349.37g·cm. The optimal ultra-high pressure (600MPa / 30min) treatment of surimi gel has a breaking strength of 302.336g, a depression depth of 14.220mm, and a gel strength of 429.775g·cm. the

[0098] Depend on figure 1 It can be seen that the breaking strength of surimi gel combined with ultrahigh pressure and heat treat...

Embodiment 3

[0123] Example 3 Determination of the pressure holding time in the process of preparing high-quality gold wire fish surimi products according to the present invention

[0124] 1. The influence of different holding time and heat treatment on the gel strength is shown in Figure 10 , 11 and 12,

[0125] Depend on Figure 10 It can be seen that in PS treatment (ultrahigh pressure + Setting), the breaking strength of surimi gel decreased significantly with the increase of pressure (p0.05). In PSH treatment (ultra-high pressure + Setting + Heating), the breaking strength of the gel holding pressure for 10 minutes is 5.95% higher than that of heat-treated gel, and 5.41% higher than that of the optimal ultra-high pressure treatment gel, and the surimi gel of holding pressure for 30 minutes and 50 minutes There was no significant difference in breaking strength (p>0.05), and the breaking strength of gels treated with PSH was significantly higher than that of gels treated with PS und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com