Sulfur-free konjak powder processing equipment

A processing equipment and konjac flour technology are applied in the field of processing equipment for sulfur-free konjac flour, which can solve problems such as high cost of sulfur dioxide residues, and achieve the effects of avoiding pollution, reducing drying process pressure and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

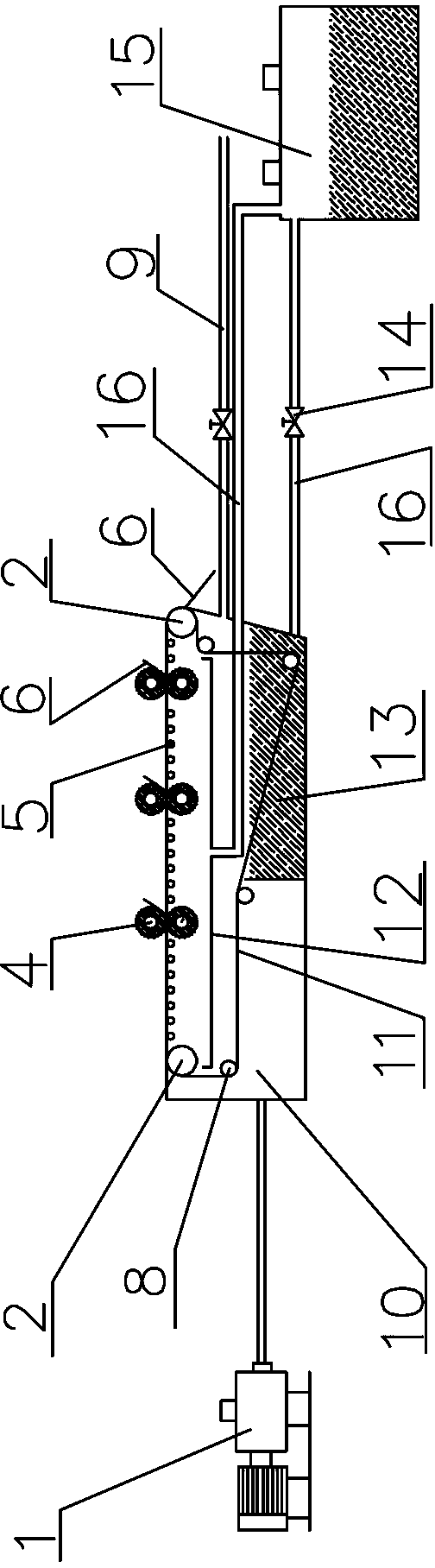

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes a vacuum chamber 10 communicated with a vacuum pump 1. An endless permeable conveyor belt 11 mounted on a transmission support steering device is installed in the vacuum chamber 10. Three pressing devices 4 are installed on the top of the endless permeating conveyor belt 11. The three squeezing devices 4 Both sides are respectively provided with material inlet 3 and material outlet 7, the lower part of the annular permeable conveyor belt 11 extends into the cleaning tank 13 located at the bottom of the vacuum chamber 10, and the vacuum chamber 10 between the circular permeable conveyor belt 11 and the cleaning tank 13 is installed There is a waste liquid collection plate 12, the upper part of the cleaning pool 13 is connected with the pure water pipeline 9, the lower part of the cleaning pool 13 and the waste liquid collecting plate 12 are connected with the water treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com