Surface roughness online detection device and method for high-temperature coating superconductive baseband

A coating and baseband technology, applied in the field of high-temperature coating superconducting baseband detection, can solve the problem of unreported surface roughness of long strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

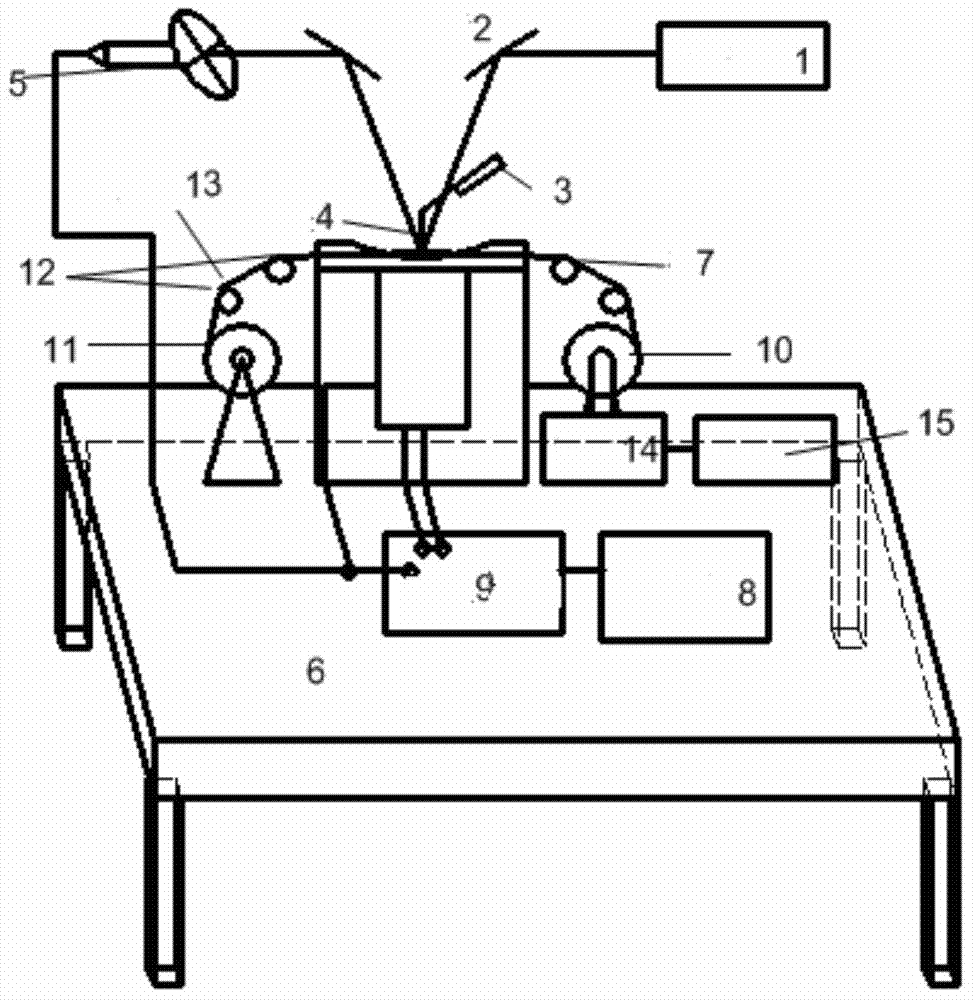

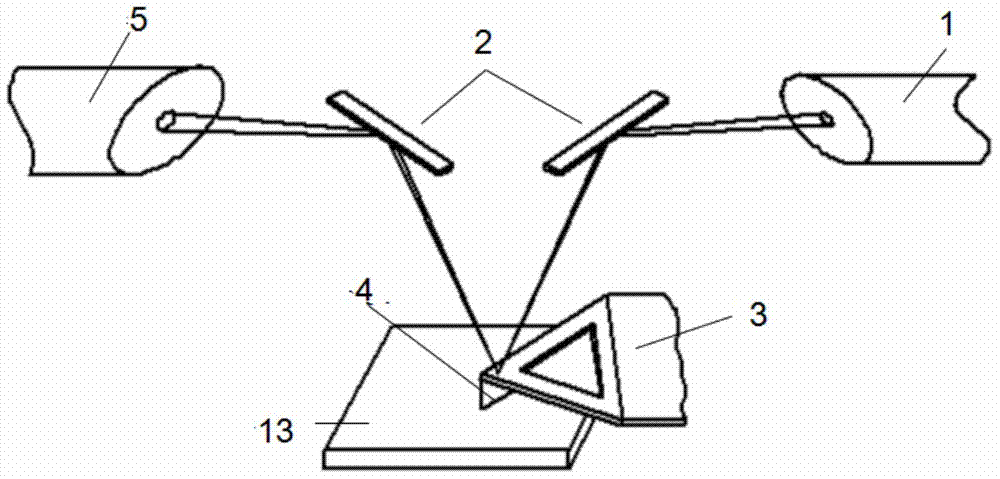

Method used

Image

Examples

Embodiment 1

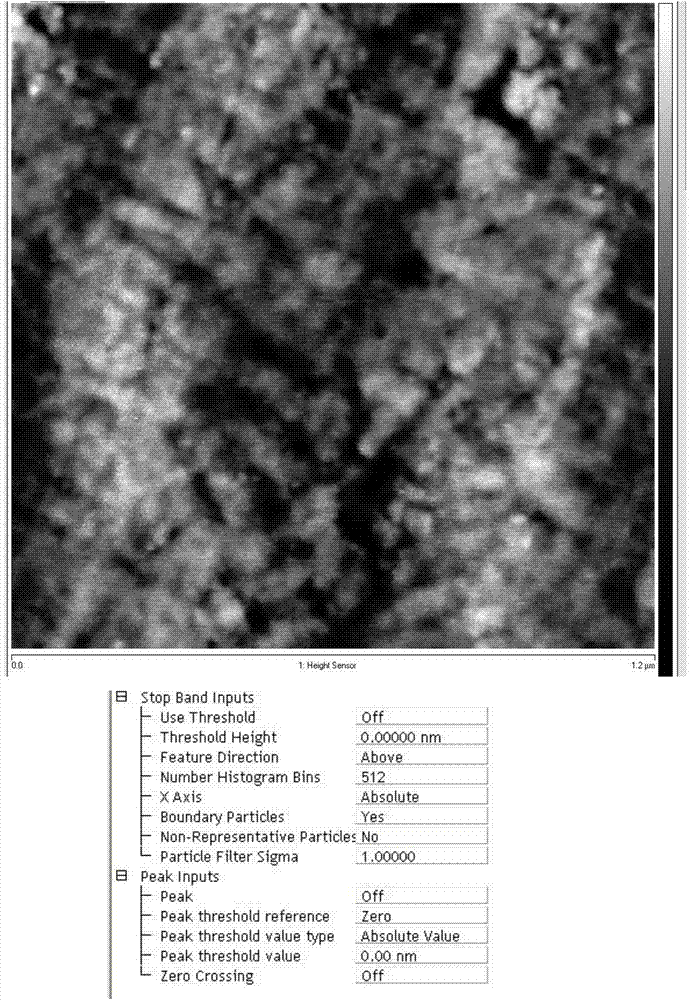

[0017] Put the probe into the probe holder, place the fully recrystallized and annealed baseband into the atomic force microscope equipment by the retractable belt system, open the operating software, and select the topography module to operate in tapping mode, so that the needle tip just touches the surface of the baseband , it can be considered that the atoms are in contact, adjust the laser and measure the resonance frequency, so that the laser signal is converted into an electrical signal and the control system (9) indicates the position of the light spot through the voltage signal converted from the light difference, and then the needle is inserted. When the needle tip is close to the sample, When the force between the needle tip and the sample reaches the set value, stop the needle insertion and start scanning. The scanning range is 1.2 μm. After the scanning is finished, a picture of the surface structure of the sample is obtained, and the picture is saved.

[0018] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com