Combustor used for gas stove

A technology for burners and gas stoves, applied in the field of kitchen appliances, can solve problems such as the inability to replenish air in time, and achieve the effects of solving uneven mixing, improving combustion sufficiency, and solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

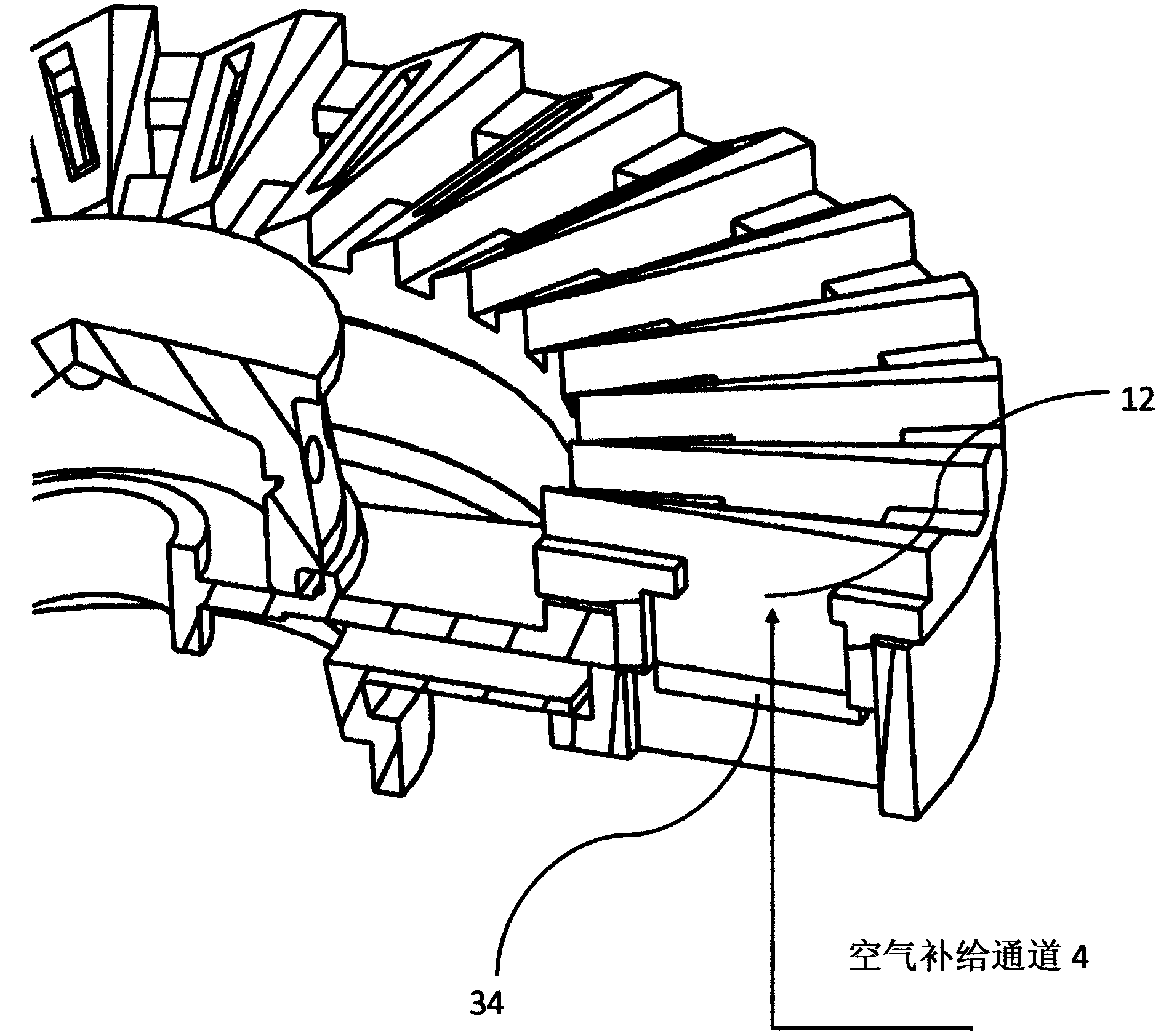

[0021] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the burner in this embodiment includes a large fire cover 1, a small fire cover 1 and a base 3. The large fire cover 1 has a fire outlet 11, an air supply channel 12 and a gas mixing chamber 13. The base 3 is a component base, which contains Base inner ring 31 , base outer ring 32 , gas mixing chamber 33 and air supply channel 34 .

[0022] Example 1, such as figure 2 with Figure 4 As shown, the gas mixing chamber 13 of the large fire cover 1 and the gas mixing chamber 33 on the base outer ring 32 of the base 3 are mechanically matched to form an integral gas mixing chamber 5 after being closely matched. The distribution of the fire holes on the fire cover should be distributed accordingly, and the number will also be designed into multiple independent gas mixing chambers according to the size of the burner and the number of fire holes in the fire cover.

[0023] Example 1, ...

Embodiment 2

[0025] Example 2, such as Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown: the burner in this embodiment includes a large fire cover 1, a small fire cover 1 and a base 3. The large fire cover 1 has a fire outlet 11, an air supply channel 12 and a gas mixing chamber 13. The base 3 is a separate base, which contains The gas mixing chamber 35 and the air supply channel 36; the formation structure of the gas mixing chamber 5 and the air supply channel 4 is the same as that of the first embodiment. The airflow direction of the mixed gas and the air supply airflow direction refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com