Clamping sleeve type metal sealing pipe joint and using method thereof

A metal seal and ferrule-type technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problem that the safe operation of the vehicle cannot be guaranteed, the structure of the double ferrule is complicated, and the reliability cannot be guaranteed. and other issues to achieve the effect of ensuring repeated times, safe and reliable sealing performance, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

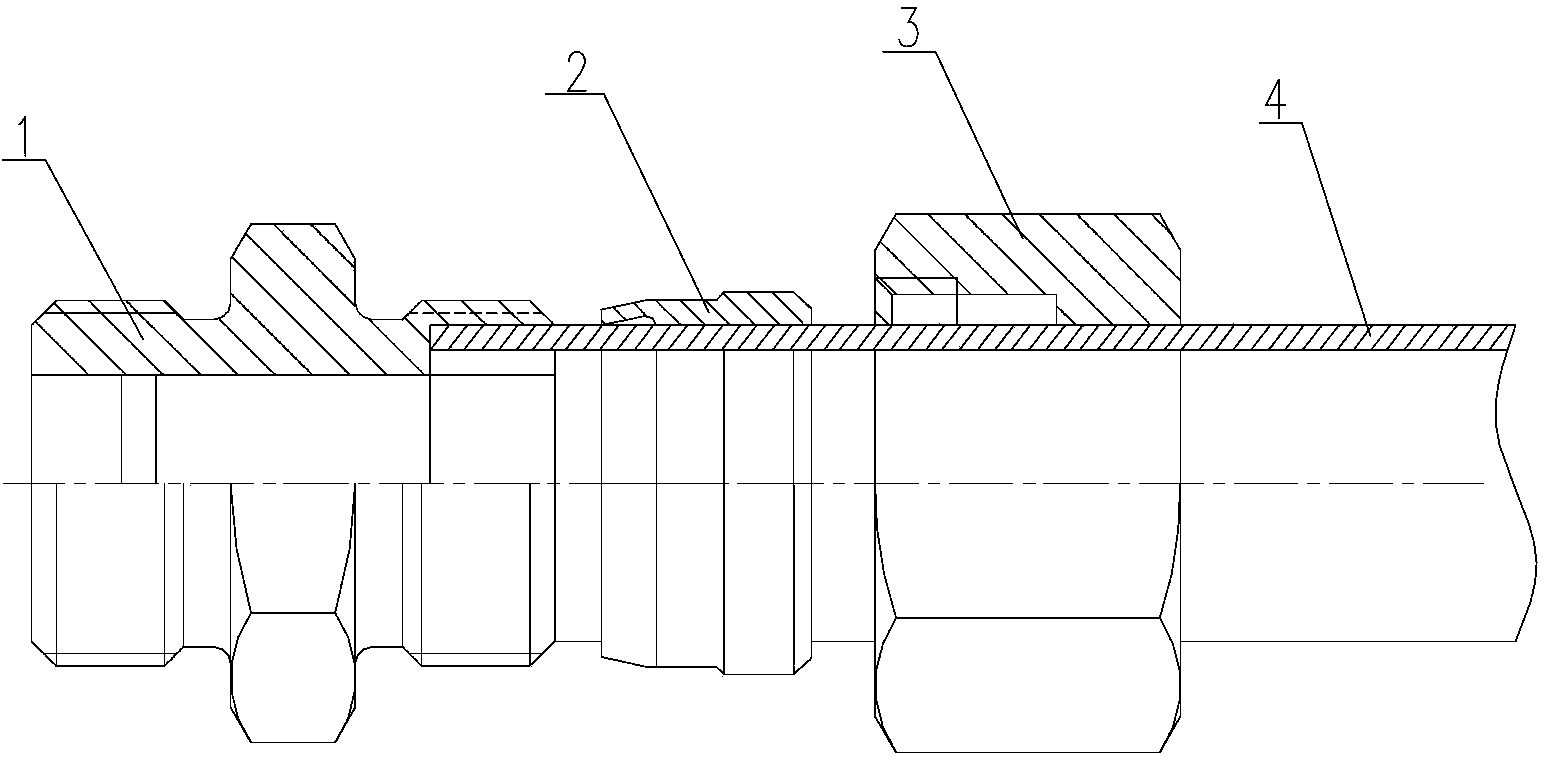

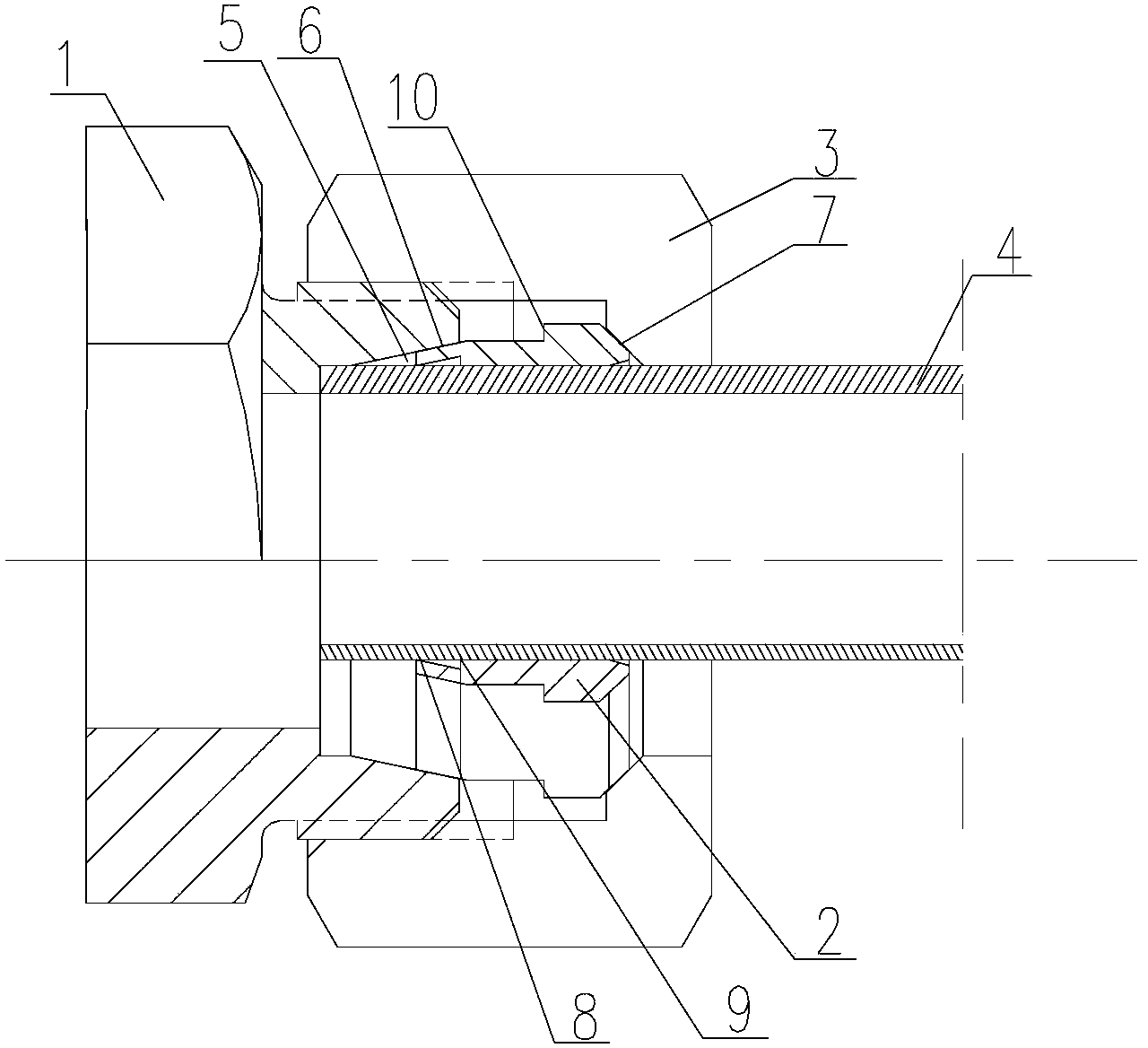

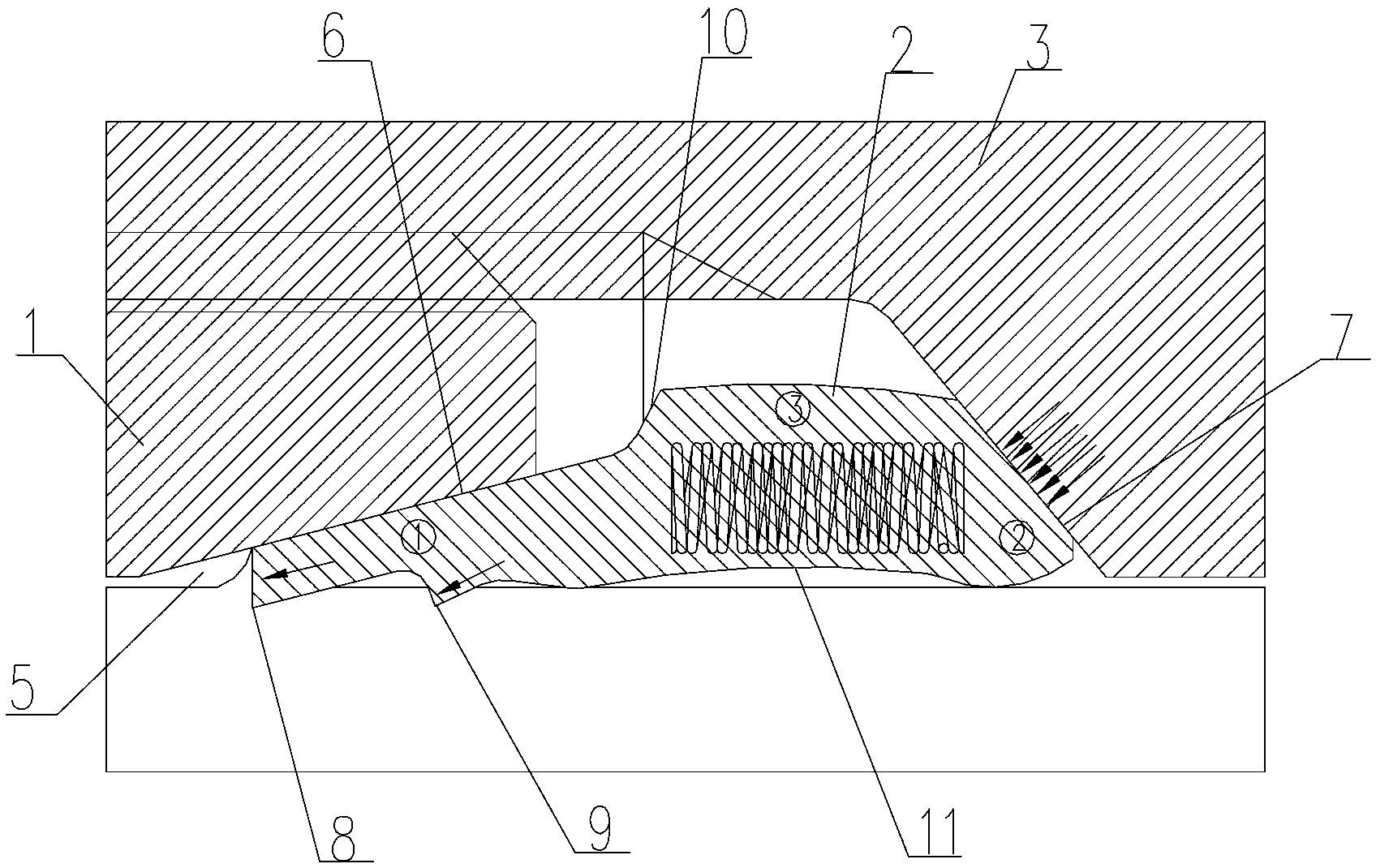

[0069] Example 1: straight-through joint assembly

[0070] Such as Figure 5 As shown, the main body is two pipes 4 that need to be connected. The ends of each pipe 4 are respectively provided with nuts 3 and ferrules 2, and are connected by a joint body 1 in the middle. The joint body 1 is a straight-through joint, and the joint body 1 Both sides of the joint body 1 have external threads connected with the nut 3, and each side has a tapered hole 5 matching the ferrule 2, and the two ends of the joint body 1 are respectively connected to two pipes through a ferrule-type metal seal connection.

Embodiment 2

[0071] Embodiment 2: right-angle joint assembly

[0072] Such as Figure 6 As shown, the main body is two pipes 4 that need to be connected. The ends of each pipe 4 are respectively provided with nuts 3 and ferrules 2, and are connected by a joint body 1 in the middle. The joint body 1 is a right-angle joint, and the joint body 1 Each of the two ends of the joint body 1 has an external thread connected with the nut 3, and each of the two ends has a tapered hole 5 matched with the ferrule 2. The two ends of the joint body 1 are respectively connected to two pipes through a ferrule-type metal seal connection.

Embodiment 3

[0073] Embodiment 3: Tee joint assembly

[0074] Such as Figure 7 As shown, the main body is three pipes 4 that need to be connected. The ends of each pipe 4 are respectively provided with nuts 3 and ferrules 2. The middle is connected by a joint body 1. The joint body 1 is a three-way joint. The joint body 1 Each of the three ends of the joint body 1 has an external thread connected with the nut 3, each of the three ends has a tapered hole 5 matching the ferrule 2, and each of the three ends of the joint body 1 is connected by a ferrule-type metal seal. Three pipes are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com