An overall active underpinning structure and underpinning method for large-tonnage multi-pile foundations of bridges

A large-tonnage, integrated technology, applied in infrastructure engineering, bridges, bridge construction, etc., can solve problems such as small safety factor, cracking of bridge superstructure, differential settlement, etc., to achieve a clear force conversion path, avoid cracking, stress Performance and Durability Reliable Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

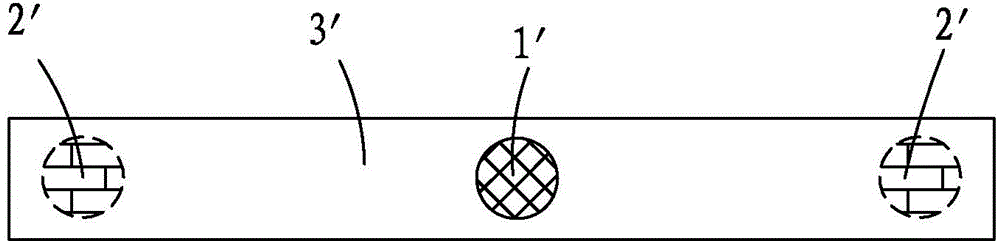

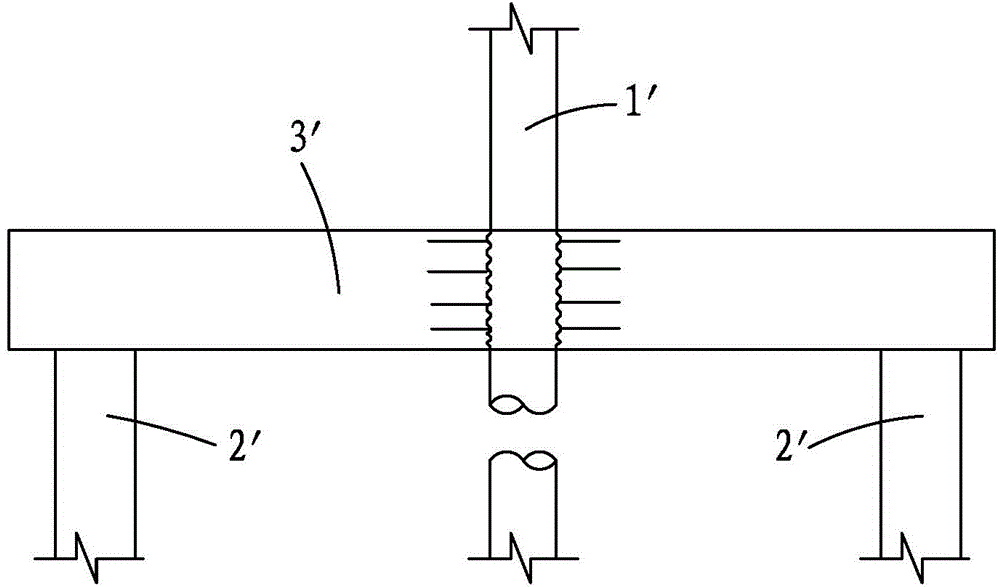

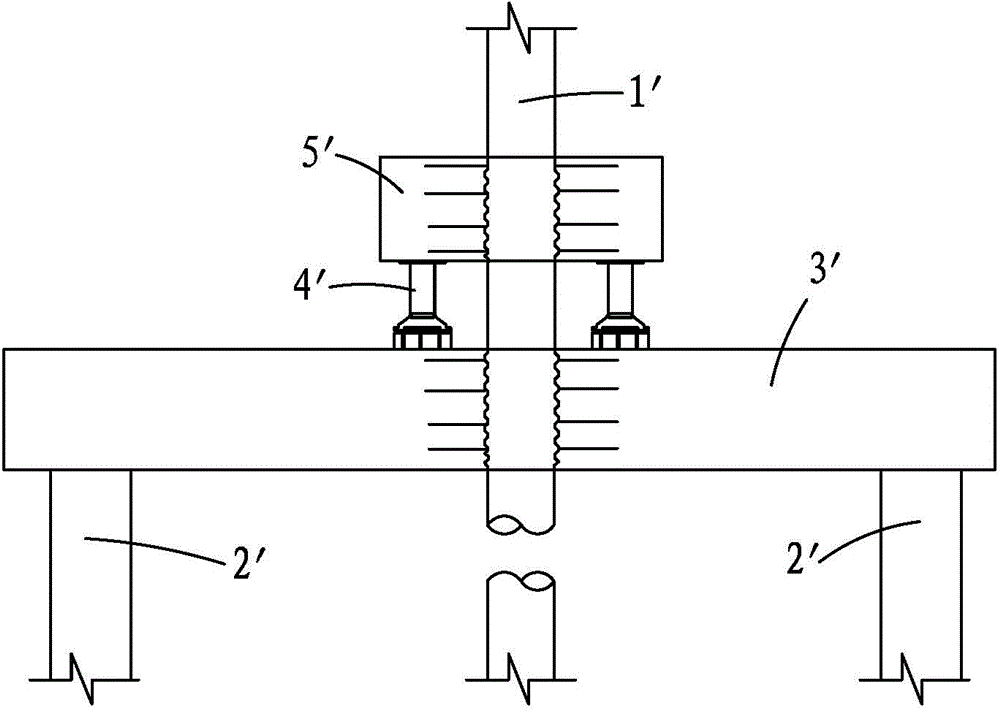

[0027] see Figure 2 to Figure 5 As shown in the figure, the overall active underpinning structure of a large-tonnage multi-pile foundation of a bridge of the present invention includes: a plurality of transverse platform beams 1, a plurality of longitudinal platform beams 2, and a plurality of rear platform beams. Casting reinforced concrete underpinning component 3;

[0028] A plurality of transverse cap beams 1 and a plurality of longitudinal cap beams 2 are cast-in-place as a whole, and a plurality of post-casting node reserved spaces 4 are reserved on the longitudinal cap beams 2; the post-cast reinforced concrete underpinning components 3 are placed in In the reserved space 4 of the post-casting node, the post-cast reinforced concrete underpinning assembly 3 includes: a hoop 31, at least four jacks 32, the main reinforcement of the pile body 33, the spiral stirrup 34, and the punching-resistant reinforcement in the beam 35 And the tension bottom reinforcement 36 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com