Composite material component rapid repairation device and method based on microwaves

A composite material component and microwave technology, which is applied in the field of rapid repairing technology and equipment for the external field of composite material components, can solve the problems of rapid repairing composite material components, large temperature gradient, low curing rate, etc., and achieves temperature control accuracy. High control accuracy and the effect of meeting repair requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

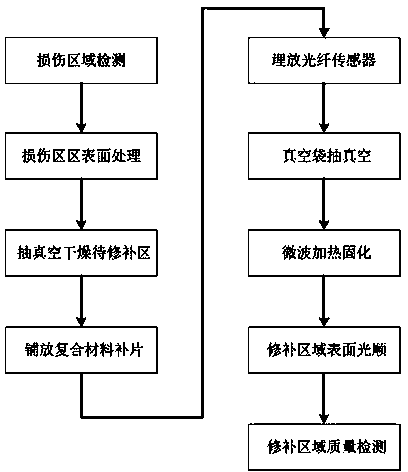

[0025] Below in conjunction with accompanying drawing technical scheme of the present invention is described in detail:

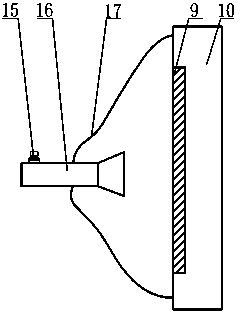

[0026] like figure 1 As shown, a rapid repair device for composite material components, one end of the microwave generating source is connected to the microwave transmission line 6, the other end of the microwave transmission line 6 is connected to the coaxial waveguide converter and one end of the dual directional coupler 7, and the coaxial waveguide converter and the dual directional coupler 7 are connected. The other end of the directional coupler 7 is connected to one end of the microwave radiator 8, and the other end of the microwave radiator 8 is relatively provided with a composite material component 10, and the side of the composite material component 10 near the composite material component 10 forms a region 9 to be repaired, to be repaired. Repair area 9 is connected with one end of signal amplifier 12 by optical fiber sensor 11, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com