Ship power station fault diagnosis method based on data fusion

A technology for data fusion and power station faults. It is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., and can solve problems such as difficulty in establishing high-precision mathematical models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

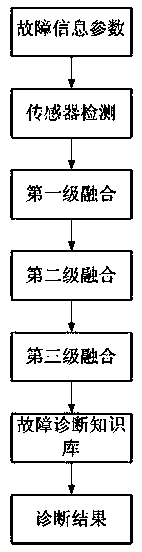

[0025] Such as figure 1 As shown, the present invention includes a plurality of sensors to monitor the fault information parameters separately, integrate the monitored data for the first level of fusion detection layer data, and eliminate the problem of unequal accuracy of the data collected by the sensors, and the data after the first level of fusion Carry out the second-level fusion to identify the dominant factors and non-dominant factors, so as to identify the dominant fault characteristic value, the data after the second-level fusion is carried out to the third-level fusion to remove uncertain information, and the fault diagnosis conclusion is obtained, then the third-level The fused diagnostic data is matched with the fault diagnosis knowledge base, and the fault diagnosis result is output.

[0026] The fault diagnosis method steps are:

[0027] a. The first level of fusion uses adaptive weighted data fusion, and the data detected by its n sensors is assumed to be , f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com