Well-drilling early overflow loss ground monitoring device

A monitoring device and overflow technology, which is applied in the directions of measurement, earthwork drilling, and flushing of boreholes, etc., can solve problems such as ineffective response to transient effects, inapplicability to drilling conditions, complex and changeable drilling activities, etc., and achieve output results Intuitive and easy, conducive to large-scale promotion, and the effect of early detection of well kick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

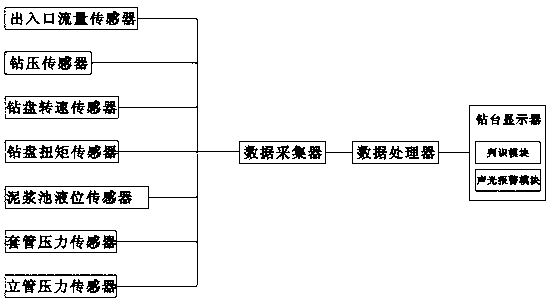

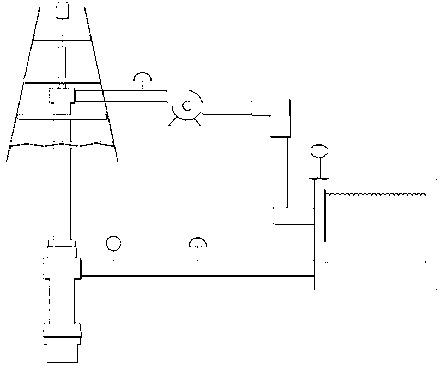

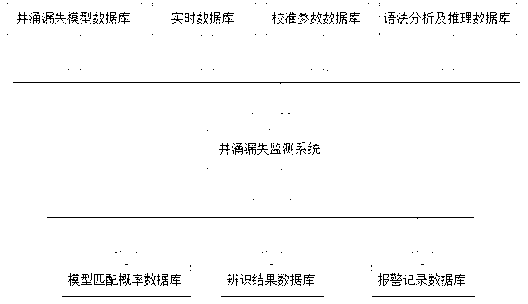

[0016] Such as Figure 1 ~ Figure 2 As shown, the surface monitoring device for early overflow and leakage of drilling includes an inlet and outlet flow sensor, a pressure on bit sensor, a drill disc speed sensor, a drill disc torque sensor, a mud pool liquid level sensor, a casing pressure sensor, and a standpipe pressure sensor. It is characterized in that , also includes a data collector, a data processor and a drill floor display connected thereto, the data collector is respectively connected with the inlet and outlet flow sensor, the drilling pressure sensor, the drill disc speed sensor, the drill disc torque sensor, the mud pool liquid level sensor, The casing pressure sensor and the standpipe pressure sensor are connected, and the data collector is connected to the drill floor display through the data processor, and the drill floor display is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com