Hot isostatic pressure diffusion welding method for tantalum target and aluminum back plate

A technology of hot isostatic pressure diffusion and welding method, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of low bonding strength, large difference in melting point, melting of solder, etc., and achieve the ability to resist deformation under heat Strong, improve the bonding strength, the effect of high bonding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

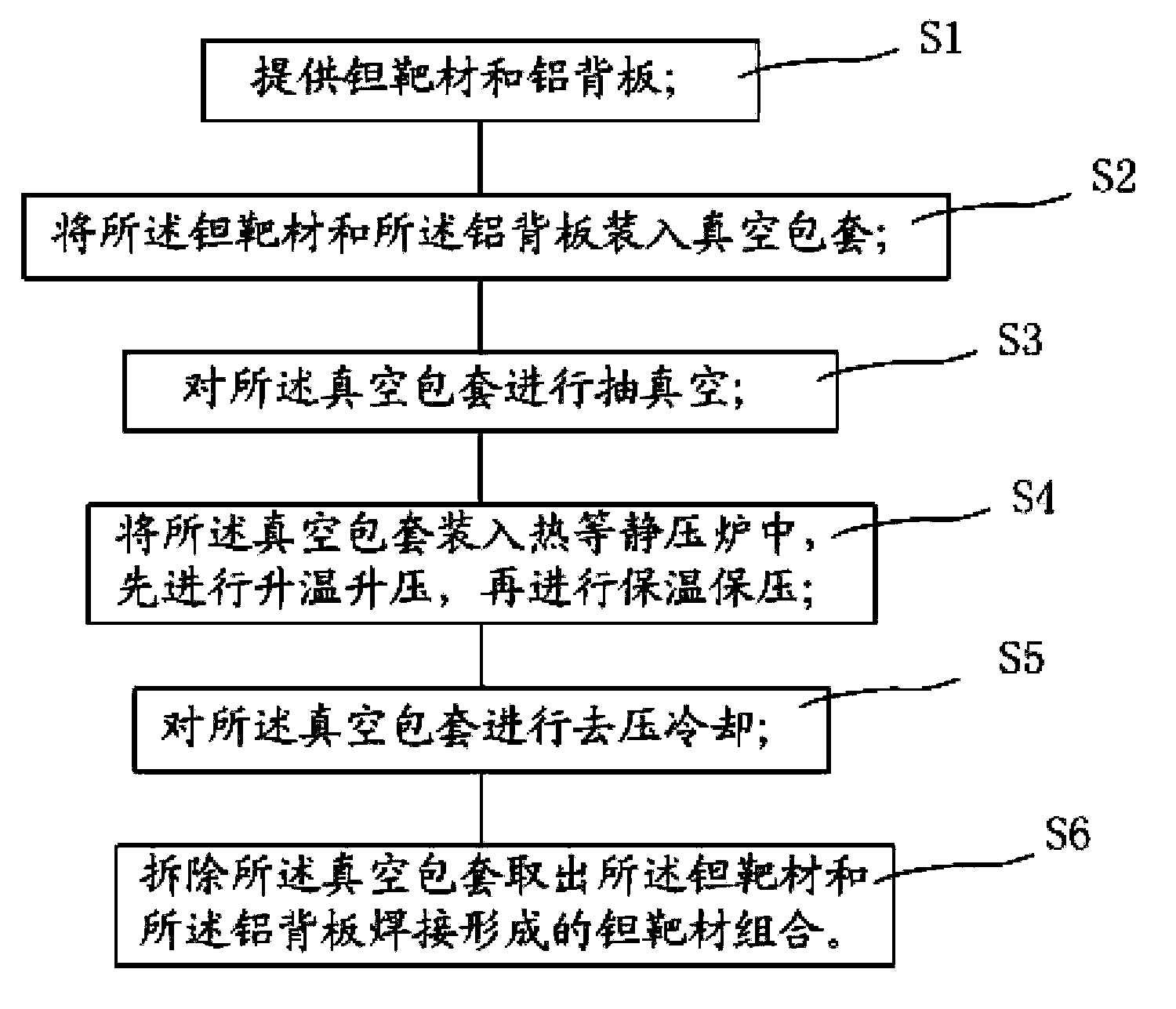

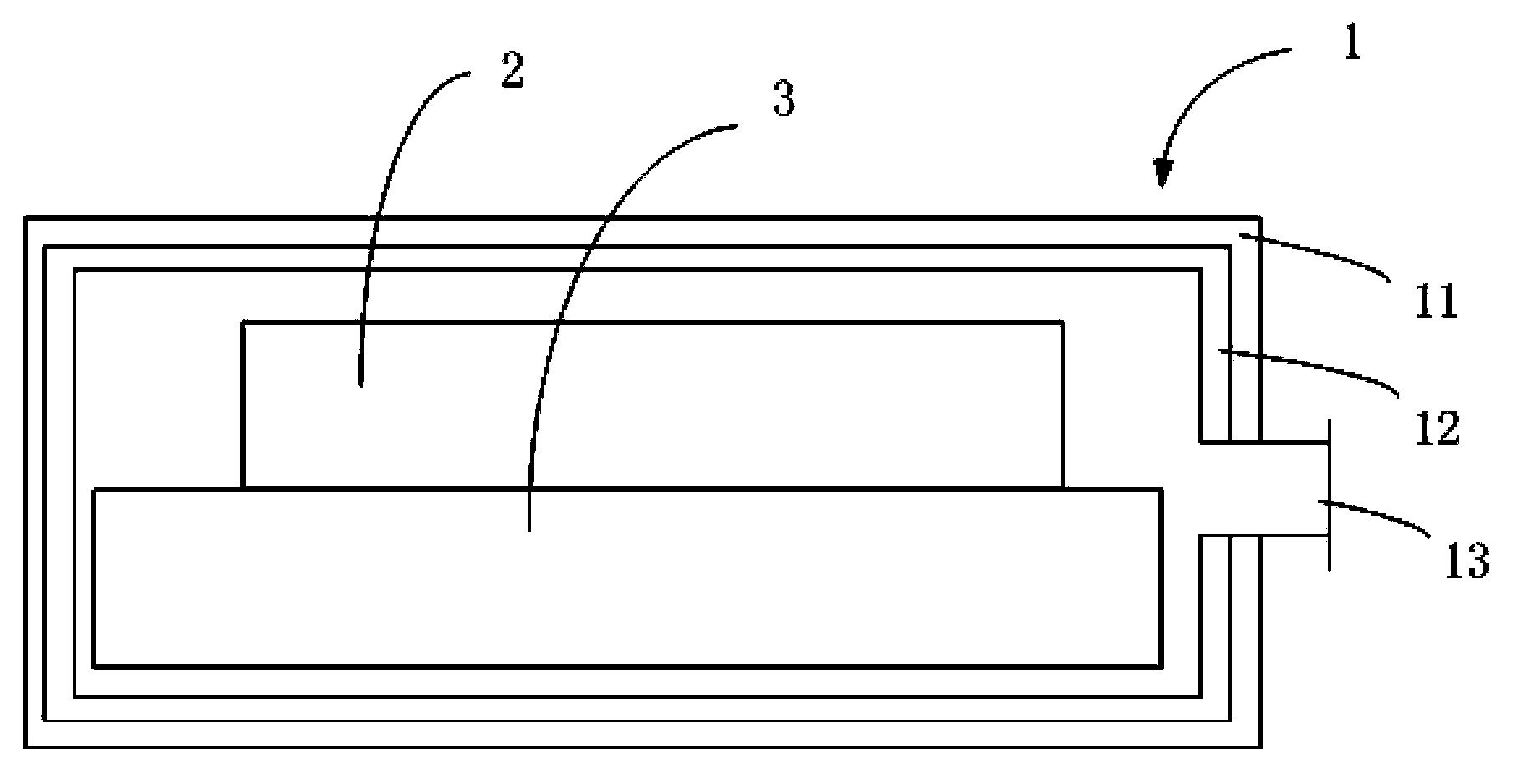

[0026] The hot isostatic pressure diffusion welding welding method of the tantalum target and the aluminum back plate provided by the embodiment of the present invention includes such as figure 1 Each of the steps shown will be described in detail below.

[0027] S1, provide tantalum target and aluminum back plate.

[0028] In the embodiment of the present invention, an aluminum back plate and a tantalum target are firstly provided. According to the actual requirements of the application environment and sputtering equipment, the shape of the tantalum target can be any of circular, rectangular, annular, conical or other similar shapes (including regular and irregular shapes), and the preferred solution is circular shape. Its diameter size is to add a machining allowance of 2mm~5mm to the design size, and its thickness dimension is to add a machining allowance of 1mm~3mm to the design size. The purpose of setting the processing allowance is to provide a relatively large proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com