Production system and method for high-grade machine-made sand and high-grade rock flour

A production system and a technology for machine-made sand, which are applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc. The effect of improving efficiency and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. In addition, this implementation case is an example, and does not constitute a limitation to the technical scope of the present invention.

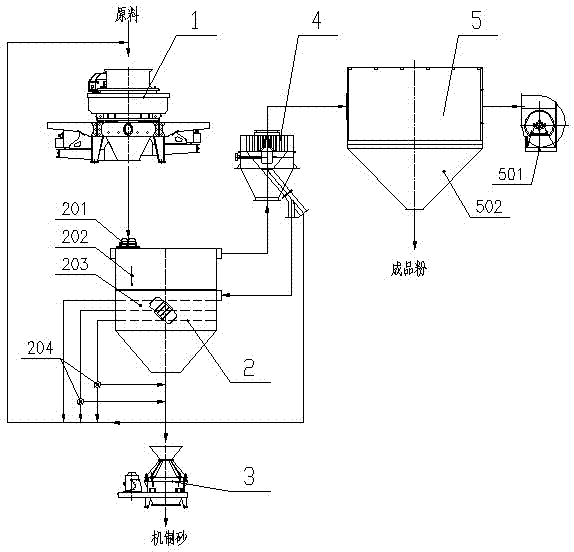

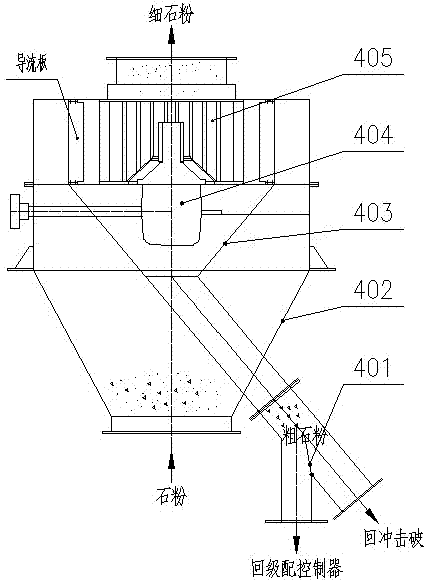

[0020] see figure 1 , a production system of high-quality machine-made sand and high-quality stone powder, which includes a crusher 1, a gradation controller 2, a particle shape optimization machine 3, a fine powder selection device 4, a negative pressure recovery device 5 and conveying equipment. After the crushed stone is crushed by the crusher 1, it is transported to the grading controller 2 by the conveying equipment, and the machine-made sand is graded to finely control the gradation of the machine-made sand. The pressure recovery device absorbs the stone powder in the machine-made sand; after the grading controller 2, a grain shape optimization machine 3 is added to optimize the grain shape of the machine-made sand; between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com