Straw combine harvester

A combined harvester and straw technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of low straw recycling efficiency, difficulty in straw recycling and high operating costs, and achieve low power, good crushing effect, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

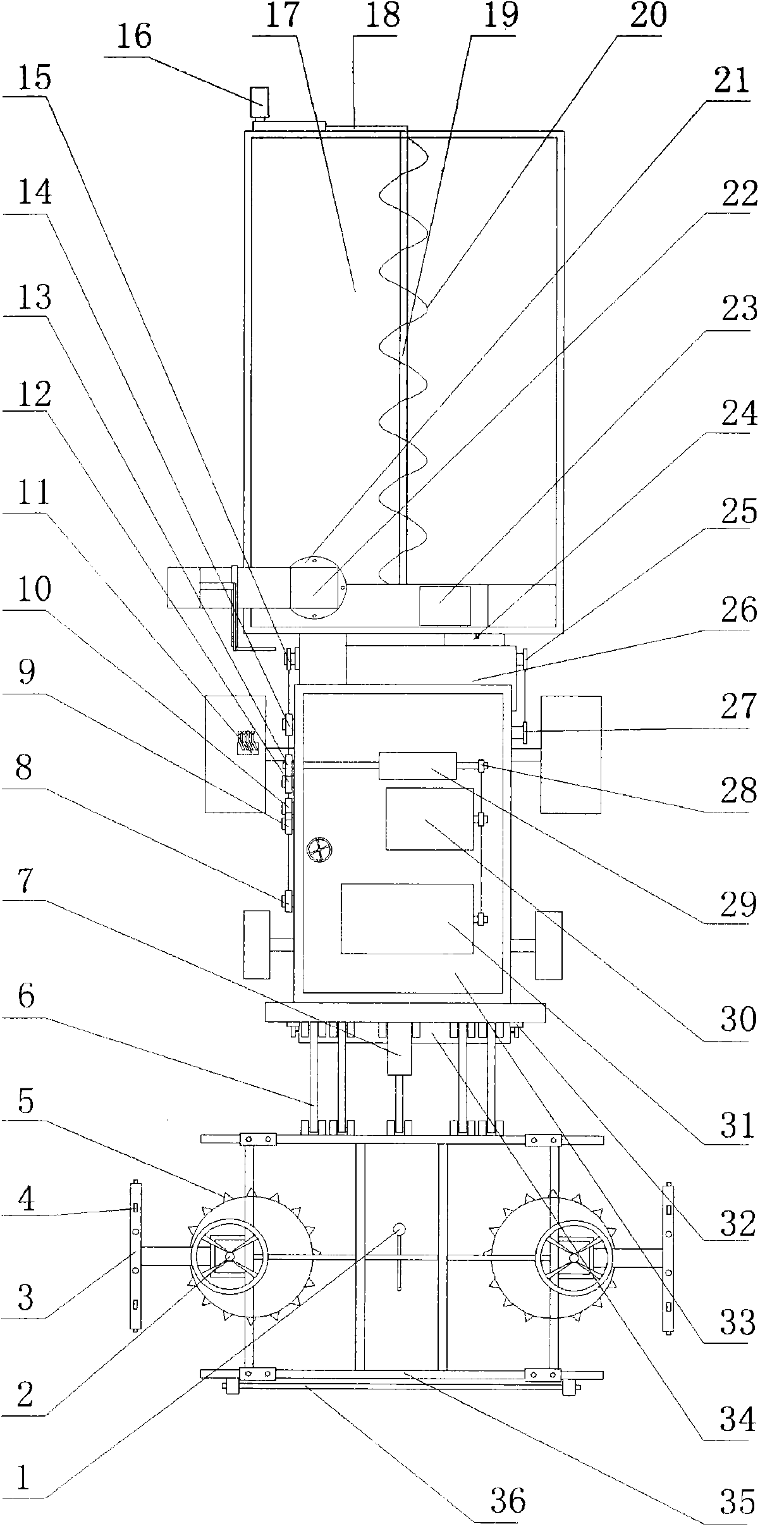

[0024] straw combine harvester, such as figure 1 , Figure 4 As shown, a motor vehicle body 33 is included. The front part of the motor vehicle body is equipped with a hydraulic lifting adjustable firewood pulling device, the lower part of the motor vehicle body is equipped with a crushing and spraying device, and the rear part of the motor vehicle body is equipped with a material storage device and a hydraulic control device;

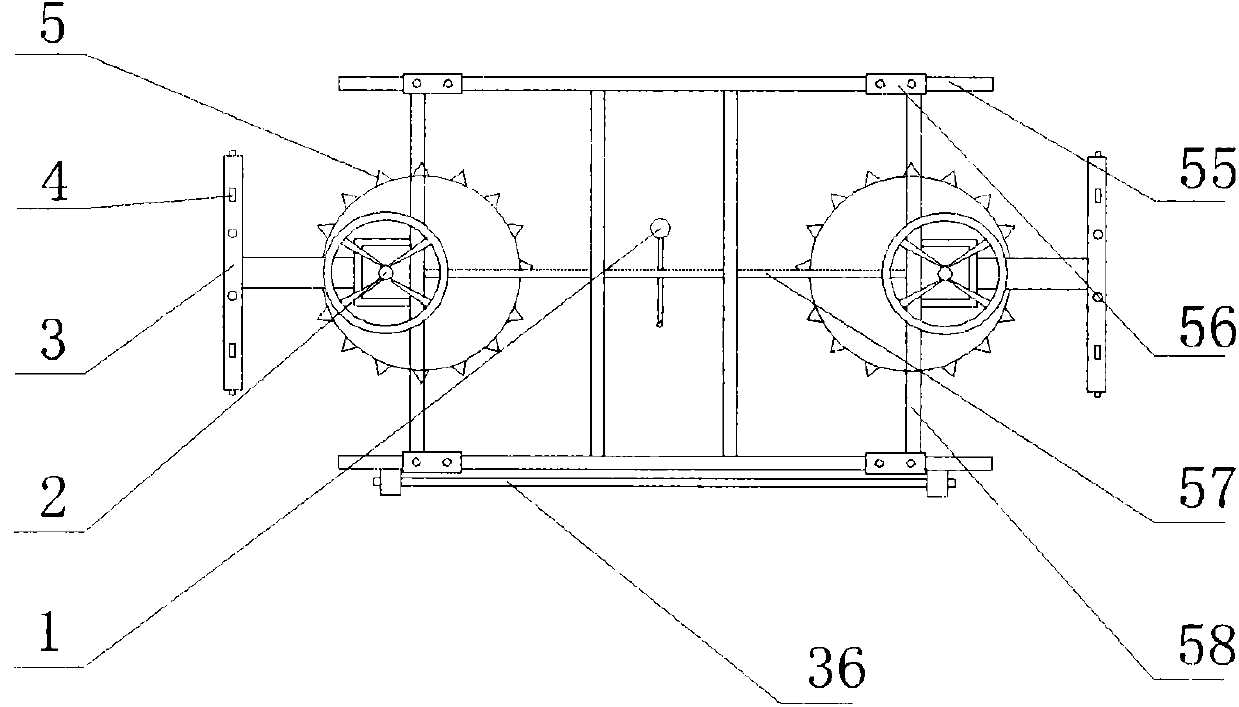

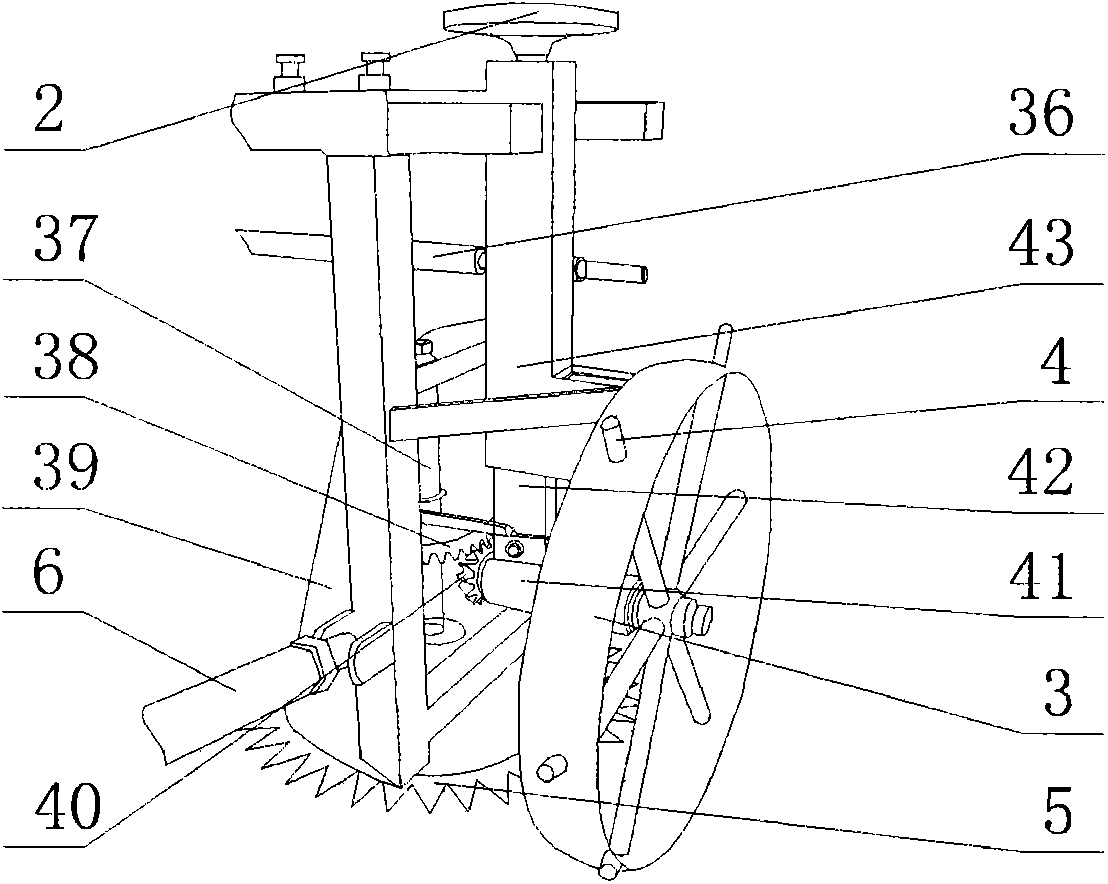

[0025] The hydraulic lifting adjustable firewood pulling device includes an adjustable pick-up frame 35 arranged at the front end of the motor vehicle body, and a connecting frame 6 that is installed between the motor vehicle body and the adjustable pick-up frame at the front end and is fixed on the motor vehicle. The front end of the vehicle body is connected with the hydraulic cylinder 7 which is driven by the adjustable pick-up frame, and the lifting firewood pulling mechanism fixed on both sides of the adjustable pick-up frame; flat roll 34. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com