Method for improving measurement accuracy of fiber optic current sensor

A fiber optic current and measurement accuracy technology, applied in the direction of measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve the problem of not being able to quickly find the resonance point for stress removal, the current ratio error of the fiber optic current sensor, the error of the test point selection, etc. problem, to achieve the effect of improving scale factor performance, improving accuracy, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment the present invention is described in further detail:

[0040] The method for improving the measurement accuracy of the optical fiber current sensor in the present invention specifically comprises the following steps:

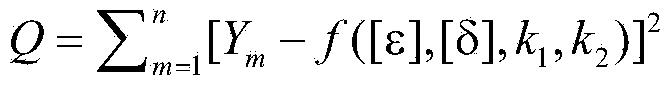

[0041] Step (1), test the stress characterization parameters of n sensitive coils, and classify the n sensitive coils according to the stress characterization parameters. The stress characterization parameters include strain parameters [ε] and linear birefringence parameters [δ]; where the strain parameters are based on The value range is divided into M categories, the linear birefringence parameters are divided into M categories according to the value range, and n sensitive coils are divided into M categories. 2 kind.

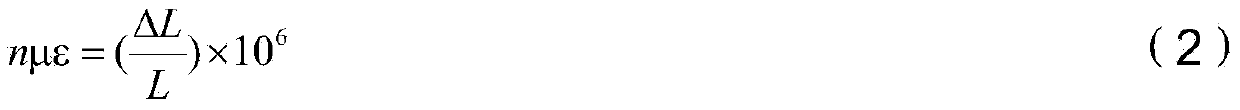

[0042] In this implementation, according to the test data of the sensitive coil, the strain parameters of the sensitive coil are divided into three categories, less than 100με is the A categ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com