Fluid storage muffler

A technology of silencer and liquid storage, applied in the direction of non-removable pipe connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of difficult welding quality assurance, increased process difficulty, and large thermal influence of copper pipes. , to achieve the effect of improving welding manufacturability, avoiding weld corrosion and ensuring welding reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technology of the present invention will be described below in conjunction with specific embodiments.

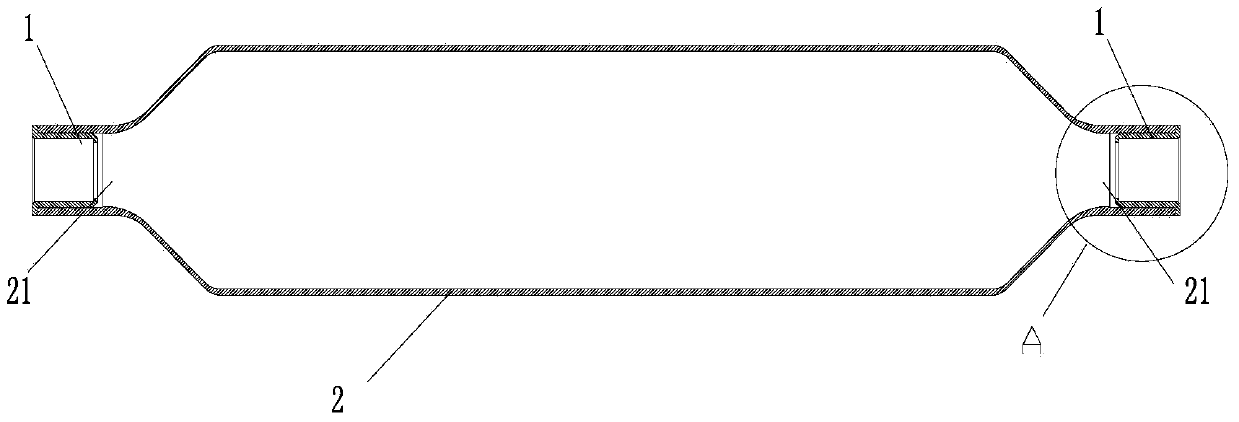

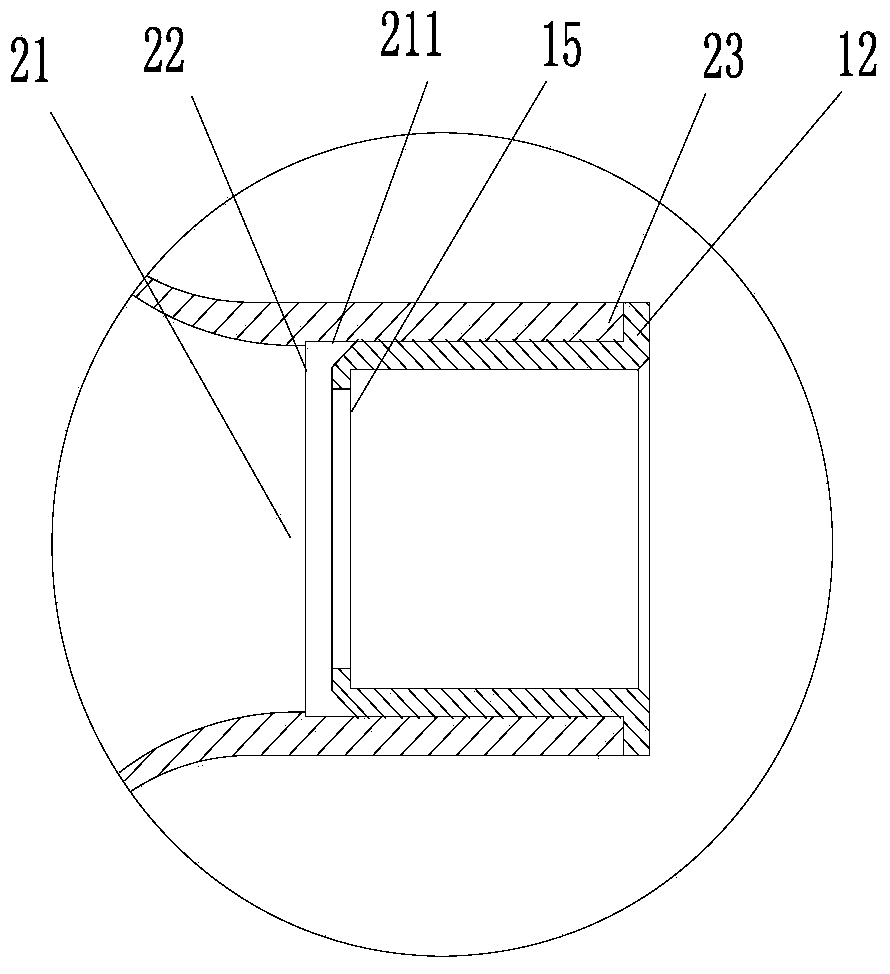

[0029] figure 1 Structural schematic diagram of the preferred liquid storage muffler provided by the present invention; figure 2 is an enlarged schematic diagram of the end position of the receiver silencer, image 3 Schematic diagram of the preferred connection sleeve.

[0030] Such as figure 1 , figure 2 and image 3 shown. The liquid storage muffler provided by the present invention adopts stainless steel pipe material to form the main body 2 through spinning, and the connection ports 21 for fluid inflow and fluid outflow are formed at both ends of the main body 2 through necking, and the inner wall surface of the connection port 21 211 is provided with a stepped surface 22 .

[0031] The connecting sleeve 1 made of copper pipe includes a generally cylindrical body part 11, a raised end part 12 is formed by flanging outward at one end of the body par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com