An automatic floating lubrication type high-lift multi-stage pump

A multi-stage pump and high-lift technology, applied in radial flow pumps, pumps, pump components, etc., can solve problems such as impeller stuck, affecting product service life, processing errors, etc., to avoid damage, prolong service life, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

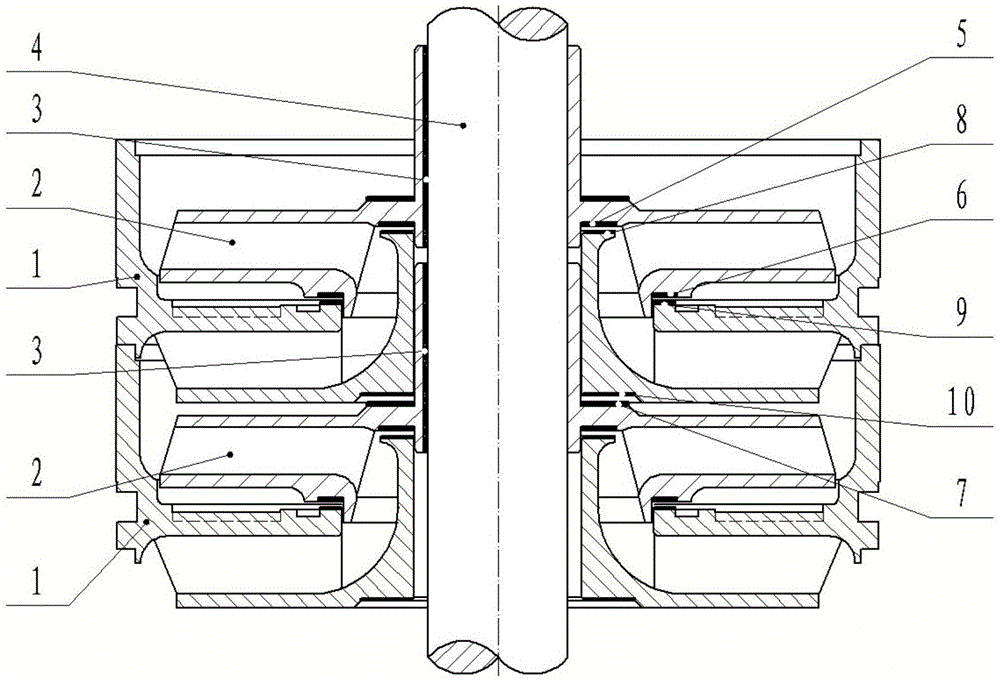

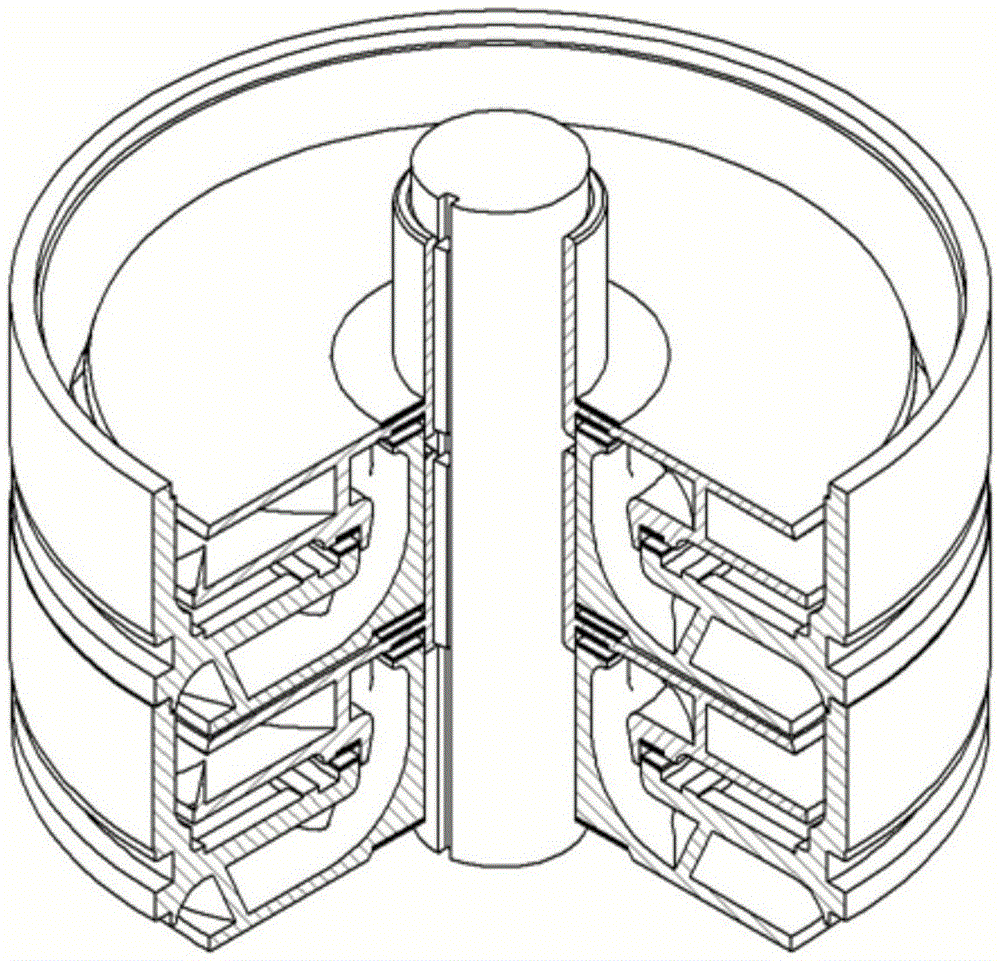

[0031] see Figure 1 to Figure 8 .

[0032] An automatic floating lubrication type high-lift multi-stage pump, which is composed of multi-stage pumps, and each stage pump includes a pump casing 1, a pump shaft 4, and an impeller 2 mounted on the pump shaft through a key 3, and the impeller 2 is located on the pump shaft. Inside the pump casing 1;

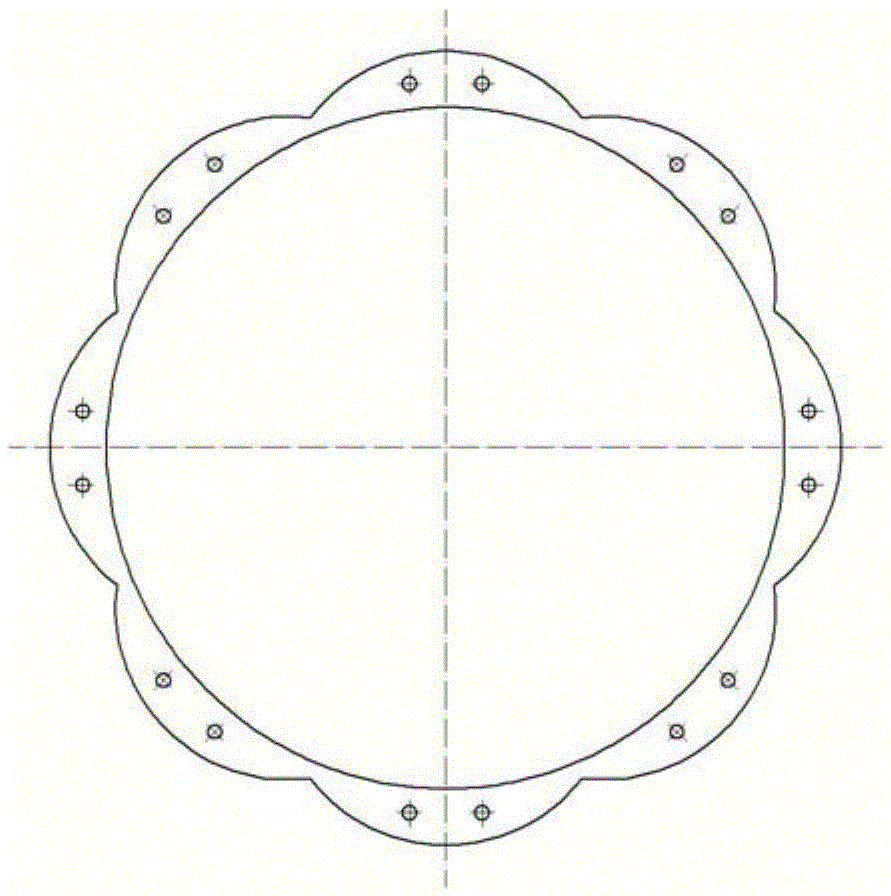

[0033] The impeller is provided with a first impeller friction plate 5, a second impeller friction plate 6 and a third impeller friction plate 7, the shape of the three impeller friction plates is a petal-shaped ring edge, and the petal-shaped ring There are several micro-holes on the top, the first impeller friction plate 5 is located at the lower end of the impeller upper cover plate along the pump shaft 4, and the second impeller friction plate 6 is located at the lower end of the impeller lower cover plate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com