High lift floating impeller well submersible pump

A submersible electric pump and floating technology, which is applied to non-variable capacity pumps, components of pumping devices for elastic fluids, pumps, etc. Serious problems, to achieve the effect of improving the installation process, reducing product parts, and eliminating the stuck pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

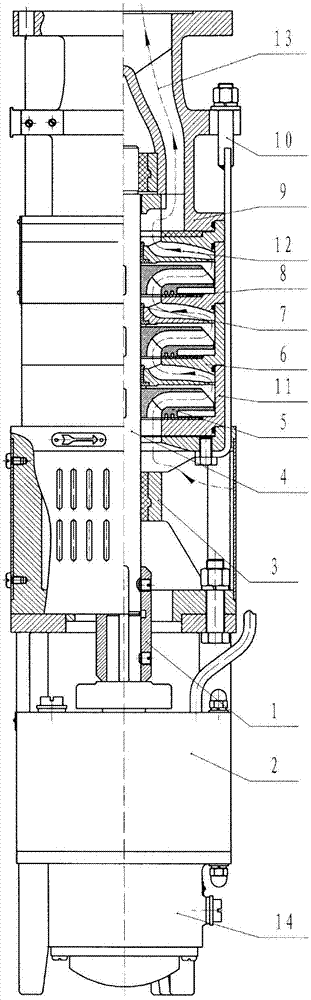

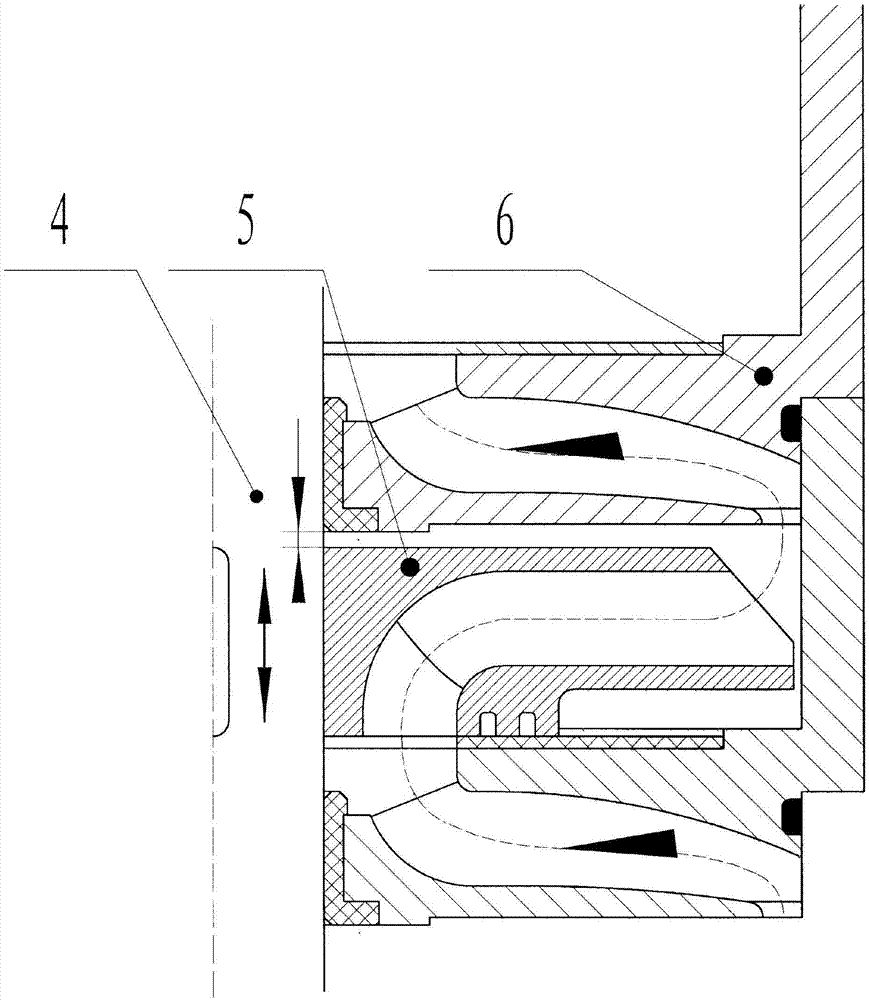

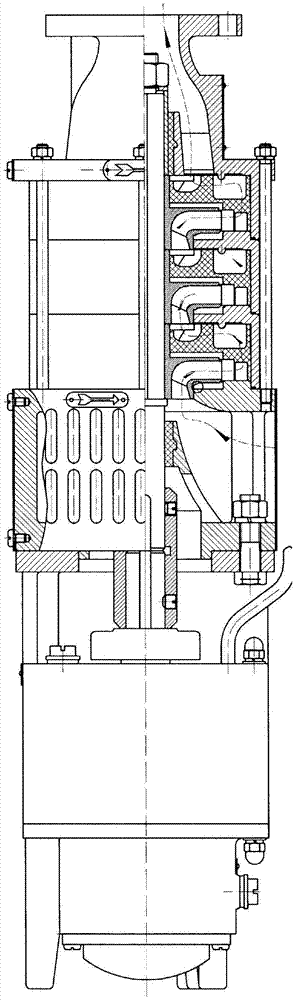

[0026] Attached below Figure 1-2 An embodiment of the present invention is described.

[0027] A high-lift floating impeller well submersible electric pump, the electric pump has a water inlet section 3, the upper end of the submersible motor 2 is fixed on the lower end surface of the water inlet section 3, the lower end is fixed on the base 14, the pump shaft 4 The lower end passes through the water inlet section 3 and is connected to the main shaft of the submersible motor 2 through the coupling 1. The connecting seat 11 is set on the pump shaft 4 and fixedly installed on the upper end surface of the water inlet section 3, and the inner cavity of the connecting seat 11 has a The water hole corresponds to the water outlet of the water inlet section 3; the first-stage impeller 5 is set on the pump shaft 4 through a key connection and is located in the inner cavity of the connection seat 11 and can move axially along the pump shaft 4, and the first The water inlet of the stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com