Guide vane type dynamic-seal self-priming pump

A vane-type, self-priming pump technology, applied in the direction of driving pumps, non-variable pumps, pumps, etc., can solve the problems of energy saving and emission reduction, reduced service life, weak self-priming ability, etc., and achieve improved Effects of hydraulic efficiency, reduction of bearing force, and improvement of cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

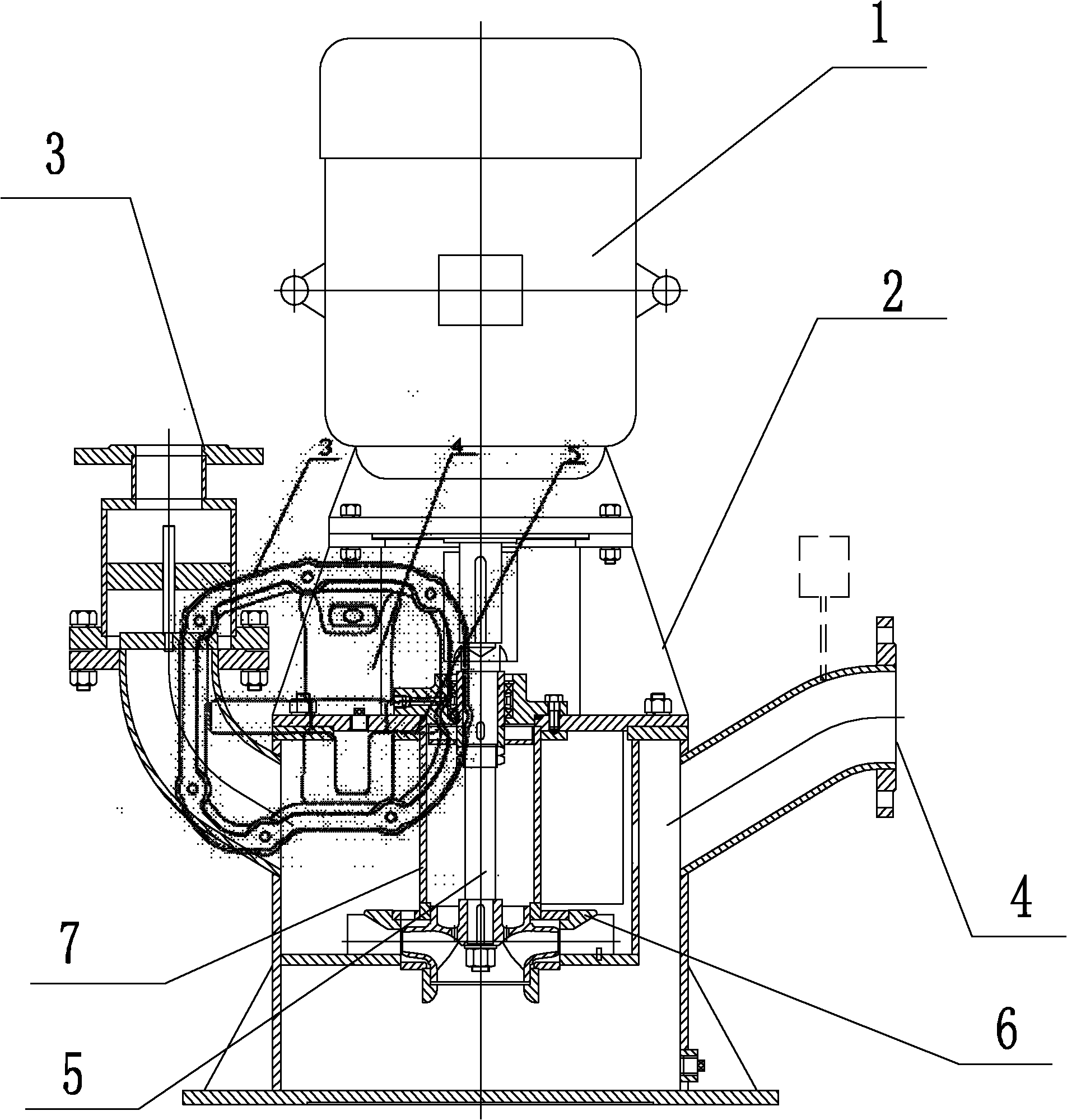

[0010] See the accompanying drawings, the guide vane type power sealed self-priming pump has a pump motor 1, a pump shaft 5, and a pump body 2. The motor 1 is arranged on the pump body 2, and the left end of the pump body 2 is set There is a liquid inlet 3, the right end of which is provided with a liquid outlet 4 connected to the liquid inlet 3, the pump shaft 5 is located on the vertical line of the pump body 2, the pump body 2 and the pump shaft 5 Equipped with auxiliary impeller dynamic sealing structure, the pump shaft 5 is provided with a guide vane 6 near the bottom end, the guide vane 6 is connected with the impeller 7, the impeller 7 is a high twist structure, and the auxiliary impeller The dynamic sealing structure includes the combination of rear port ring 8 sealing and balance hole 9 .

[0011] The specific examples described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be underst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com