Brake pump piston ring of car air compressor

An air compressor and piston ring technology, applied in the field of piston rings, can solve the problems of large exhaust gas and unfavorable air compressor sealing, and achieve the effects of reducing down exhaust gas, preventing oil from running up, and improving the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

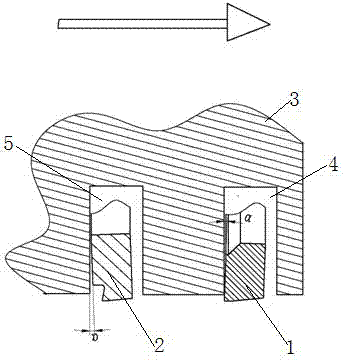

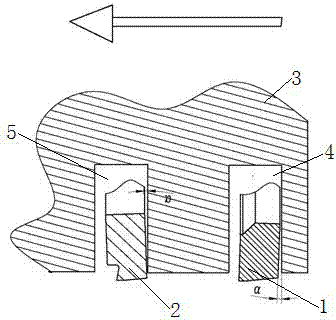

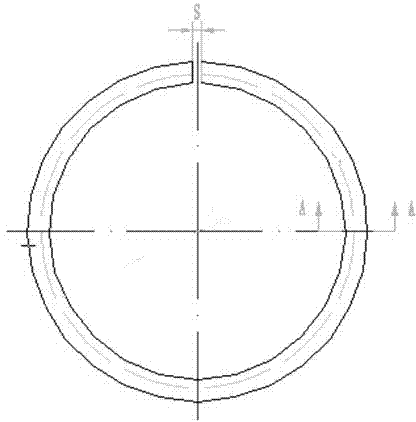

[0016] Example: A piston ring of a brake pump for a vehicle air compressor, comprising a first ring 1 and a second ring 2, and a first piston ring groove for inserting the first ring 1 is formed along the circumference from top to bottom of the piston 3 4 and the second piston ring groove 5 embedded in the second ring 2, the first ring 1 is an anti-twisted tapered ring, the second ring 2 is a positively twisted tapered ring, and the closed gap S between the two rings is 0.10mm, such as image 3 Shown; the taper angle of the first ring 1 is 2°±30′, such as Figure 4 Shown; the taper angle of the second ring 2 is 2°±30′, such as Figure 5 Shown; when the piston 3 is on the stroke, such as figure 1 As shown, the positive and negative twisted rings in the working state produce a small twist angle α under the action of twisting. Among them, the reverse twist angle α generated by the anti-twisted ring makes the outer side of the lower end surface of the anti-twisted ring contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com