Method for preparing reactive printing paste taking starch as raw material

A technology of reactive printing and starch, applied in the field of paste, can solve problems such as increasing equipment investment, and achieve the effects of improving reaction uniformity, high degree of substitution and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

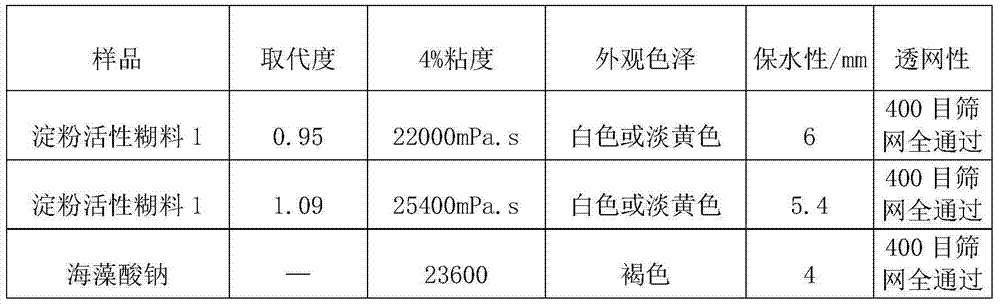

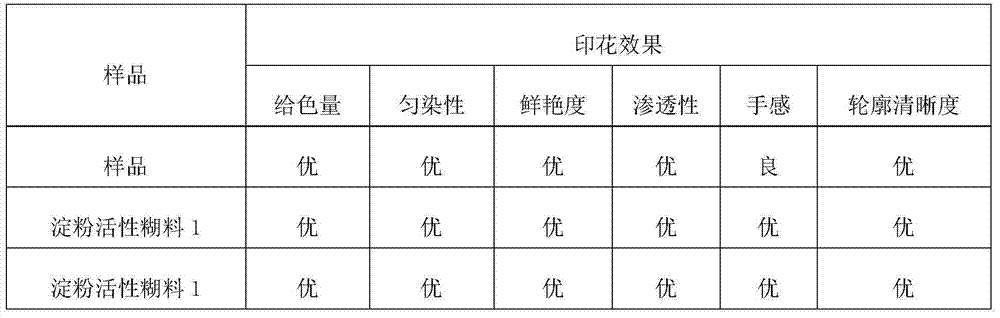

Examples

Embodiment 1

[0054]Slowly add 100kg of starch to the reactor at a stirring speed of 160r / min, then add 20kg of methanol aqueous solution with a mass ratio of 85% by spraying, continue stirring for 10min, then slowly add 50kg of 200-mesh powdered sodium hydroxide and 1kg of penetrant OEP- 70, react at 35°C for 15 minutes, then add 60kg of solid chloroacetic acid, and react at 60°C for 20 minutes. After the reaction, the reaction materials were transferred to a static reaction chamber, and reacted statically at 50° C. for 8 hours. After the static reaction is over, the reaction product is dried and pulverized to obtain the active printing paste.

Embodiment 2

[0056] Slowly add 100kg of starch to a 1000L reactor at a stirring speed of 200r / min, then add 45kg of 80% ethanol aqueous solution by spraying, continue stirring for 10min, then slowly add 60kg of 200-mesh powdered sodium hydroxide and 1.2kg of penetrant AEP, react at 25°C for 25min, then add 70kg of solid chloroacetic acid, react at 60°C for 20min. After the reaction, the reaction materials were transferred to the secondary reaction chamber, and reacted statically at 55° C. for 12 hours. After the secondary reaction, the reaction product is dried and pulverized to obtain the active printing paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com