Spin forming element for air-jet spinning machine with insert and associated spinneret

An air-jet spinning machine and spinneret technology, applied in the field of spinning forming elements, can solve problems such as unfavorable yarn ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

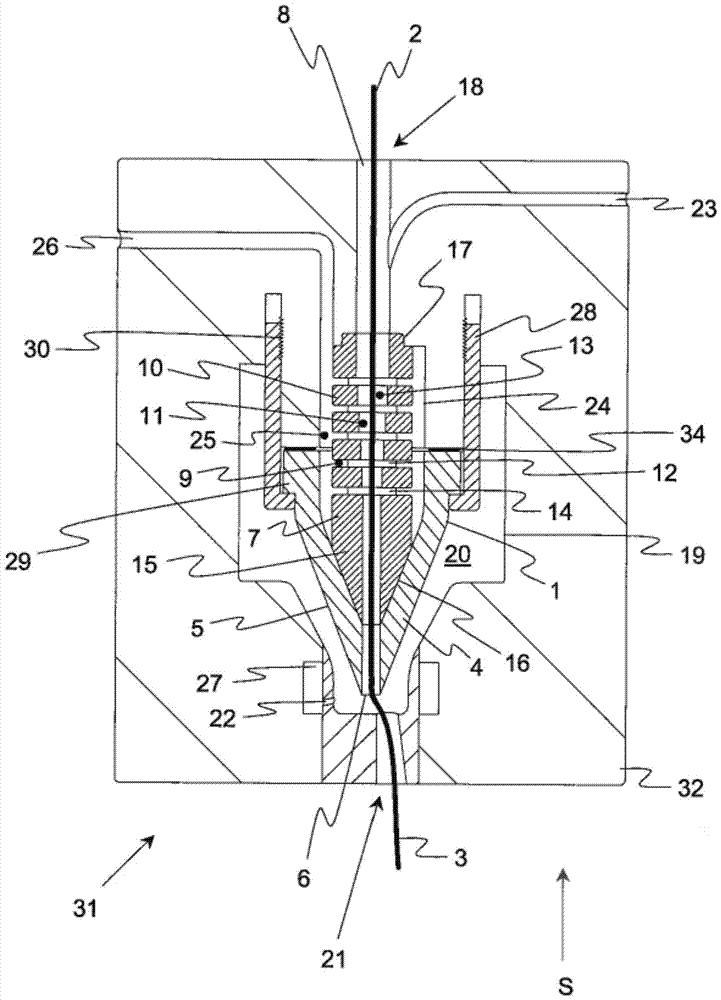

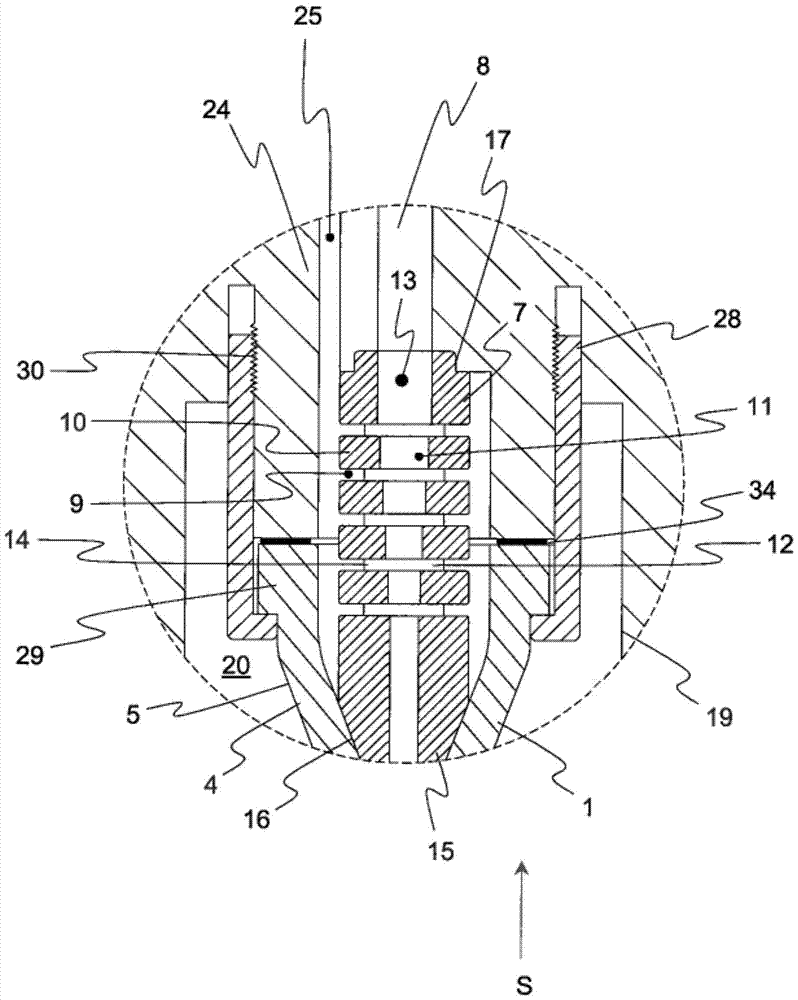

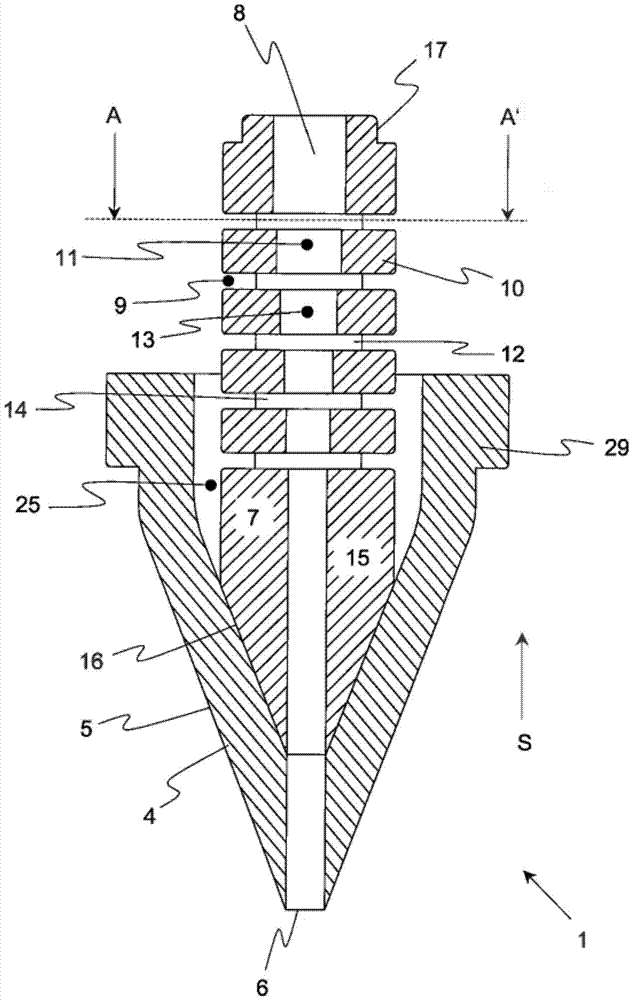

[0037] As mentioned earlier, there are multiple parts of the same type in the diagram (e.g. Figure 1 to Figure 4 The plate 10 in ), generally only one of a plurality of parts of the same type is marked with a reference numeral to ensure its clarity.

[0038] figure 1 Shown is a spinneret 31 (generally comprising a plurality of corresponding spinnerets 31 ) of an air-jet spinning machine designed according to the invention. The spinneret 31 has a housing 32 with a feed opening 21 through which the fiber bundle 3 (for example conveyed by the pre-stored drawing equipment of the spinneret 31 ) is conveyed into the vortex chamber 20 internally surrounded by the vortex inner wall 19 .

[0039] A plurality of air nozzles 22 are installed in the vortex chamber 20, and they are supplied with compressed air through an annular channel 27 connected to an air pressure source. With the aid of the air flow into the vortex chamber 20 (preferably tangential inflow), a spinning composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com