A kind of plant modified polymeric putty adhesive and preparation method thereof

An adhesive and putty technology, which is used in the field of plant-modified polymer putty adhesive and its preparation, can solve the problem of bonding strength (the adhesion cannot meet the requirements, the construction performance of the putty powder is affected, and the bonding strength has little effect). And other problems, to achieve the effect of not easy to empty drum to remove powder, improve lubricity, good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

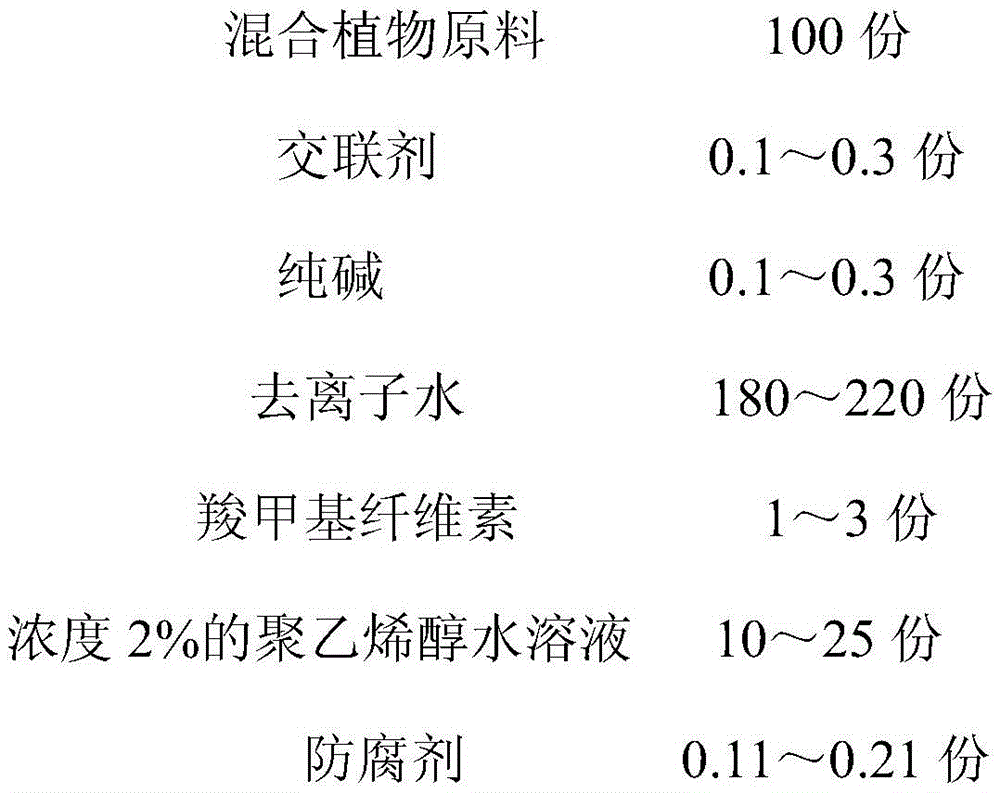

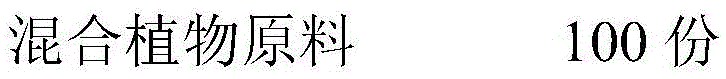

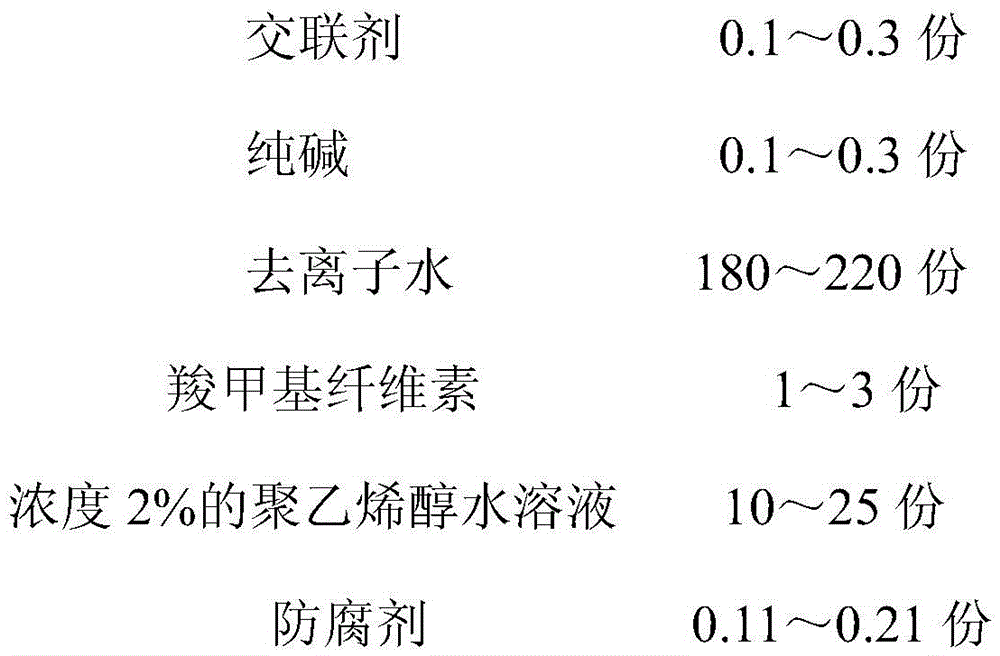

[0029] A kind of preparation method of plant-modified polymerization putty adhesive is specifically as follows:

[0030] (1) Using konjac and potato as the main ingredients, first wash them to remove impurities and peel them, weigh 33 kg of konjac and 67 kg of potato, grind and mix them to form a mixed plant material of konjac and potato, and then Add 0.1 kg of monochloroacetic acid, 0.1 kg of soda ash and 180 kg of deionized water in sequence, and react for 20 to 40 minutes at 1 to 2 atmospheres and 100 to 130°C to form a mixed glue;

[0031] (2) Mix polyvinyl alcohol and deionized water at a mass ratio of 2:98, boil at 95-98°C for 1-2 hours, and then cool naturally to form a transparent gel-like liquid, that is, polyvinyl alcohol with a concentration of 2%. Aqueous solution of vinyl alcohol;

[0032] (3) Add 10 kilograms of 2% polyvinyl alcohol aqueous solution, 0.11 kilograms of food-grade preservatives and 3 kilograms of carboxymethyl cellulose to the mixed solution forme...

Embodiment 2

[0034] A kind of preparation method of plant-modified polymerization putty adhesive is specifically as follows:

[0035] (1) Using konjac and potato as the main ingredients, first wash them to remove impurities and peel them, weigh 50 kg of konjac and 150 kg of potato, grind and mix them to form a mixed plant material of konjac and potato, and then Add 0.6 kg of trichloroacetic acid, 0.6 kg of soda ash and 440 kg of deionized water in sequence, and react for 20 to 40 minutes at 1 to 2 atmospheres and 100 to 130°C to form a mixed glue;

[0036] (2) Mix polyvinyl alcohol and deionized water at a mass ratio of 2:98, boil at 95-98°C for 1-2 hours, and then cool naturally to form a transparent gel-like liquid, that is, polyvinyl alcohol with a concentration of 2%. Aqueous solution of vinyl alcohol;

[0037] (3) Add 50 kilograms of 2% polyvinyl alcohol aqueous solution, 0.42 kilograms of food-grade preservatives and 3 kilograms of carboxymethyl cellulose to the mixed solution forme...

Embodiment 3

[0039] A kind of preparation method of plant-modified polymerization putty adhesive is specifically as follows:

[0040] (1) Using konjac and potato as the main ingredients, first wash them to remove impurities and peel them, weigh 25 kg of konjac and 75 kg of potato, grind and mix them to form a mixed plant material of konjac and potato, and then Add 0.2 kg of monochloroacetic acid, 0.2 kg of soda ash and 200 kg of deionized water in sequence, and react for 20 to 40 minutes at 1 to 2 atmospheres and 100 to 130 ° C to form a mixed glue;

[0041] (2) Mix polyvinyl alcohol and deionized water at a mass ratio of 2:98, boil at 95-98°C for 1-2 hours, and then cool naturally to form a transparent gel-like liquid, that is, polyvinyl alcohol with a concentration of 2%. Aqueous solution of vinyl alcohol;

[0042] (3) Add 18 kg of 2% polyvinyl alcohol aqueous solution, 0.16 kg of food-grade preservative and 1 kg of carboxymethyl cellulose to the mixed solution formed in step (1) and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com