High-efficiency running method by using sequencing batch full-autotrophic denitration granular sludge

A technology for full autotrophic denitrification and granular sludge, applied in the field of full autotrophic denitrification (CANON) process granular sludge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] The efficient operation method of sequencing batch type full autotrophic denitrification granular sludge, the influent is to add a certain amount of (NH 4 ) 2 SO 4 , NaHCO 3 and KH 2 PO 4 It is configured, and an appropriate amount of trace elements are added at the same time. The specific water quality is as follows:

[0034] The mass concentration of ammonia nitrogen is 380-420mg / L, the mass concentration of phosphate is 5-10mg / L, the mass concentration of alkalinity (as CaCO 3 Total) is 1400-2000mg / L. The dosage of the trace element mixture is 1mg / L, including (mg / L):

[0035] Nutrient solution I: EDTA5.00FeSO 4 .7H2O5.00 nutrient solution II: EDTA15.00H 3 BO 4 0.014MnCl 2 .4H 2 O0.099CuSO 4 .5H 2 O0.25ZnSO 4 .7H 2 O0.43NiCl 2 .6H 2 O0.19Na 2 SeO 4 .10H 2 O0.21Na 2 MoO 4 .2H 2 O0.22NaWO 4 .2H 2 o

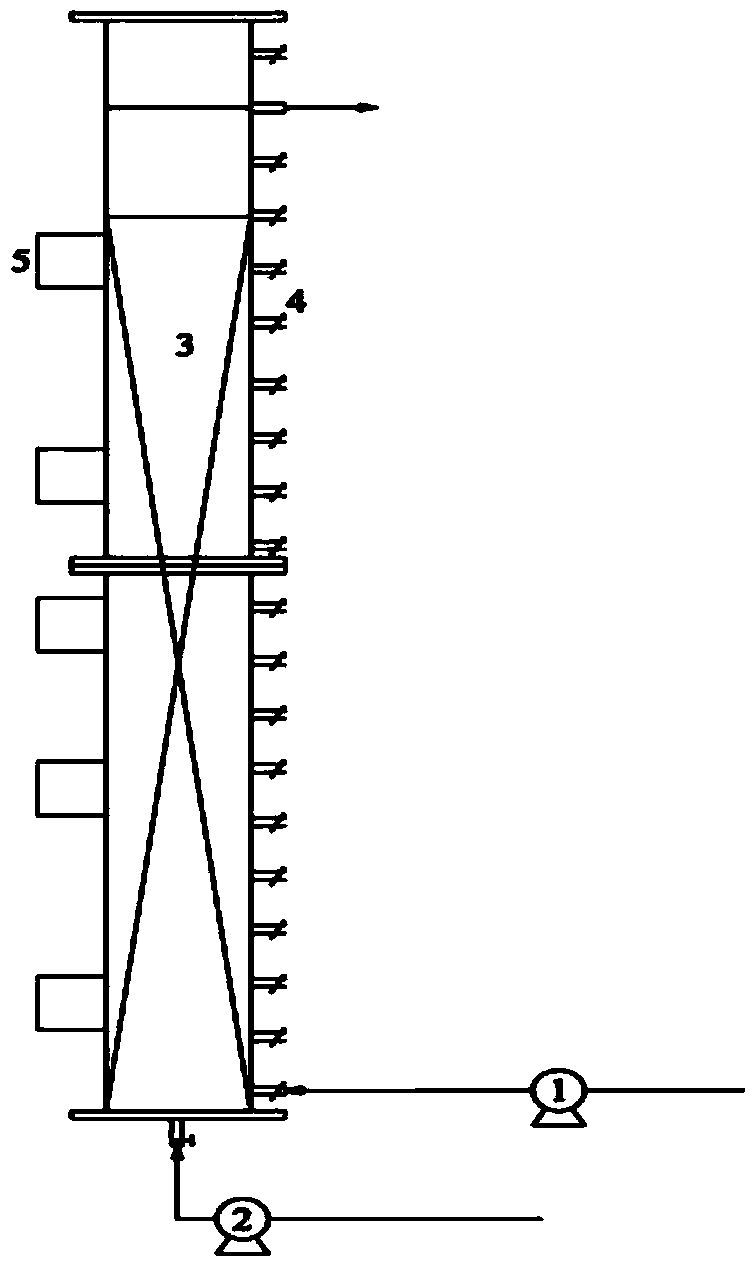

[0036] Reactor form: The reactor is made of plexiglass, cylindrical, with an inner diameter of 7mm, a total height of 1000mm, a total volume of 3...

Embodiment 2

[0040] The water inflow of embodiment two is basically the same as that of embodiment one, the main difference lies in the form of the reactor.

[0041] Reactor form: The reactor is made of plexiglass, cylindrical, with an inner diameter of 15mm, a total height of 500mm, a total volume of 8.83L, and an effective volume of 7L. Due to the large cross-sectional area of the reactor, the ordinary aeration ring has uneven aeration, so a sand tray aeration device is used at the bottom, and the aeration volume is controlled by a gas rotameter. Seed slime and embodiment one come from the same reactor.

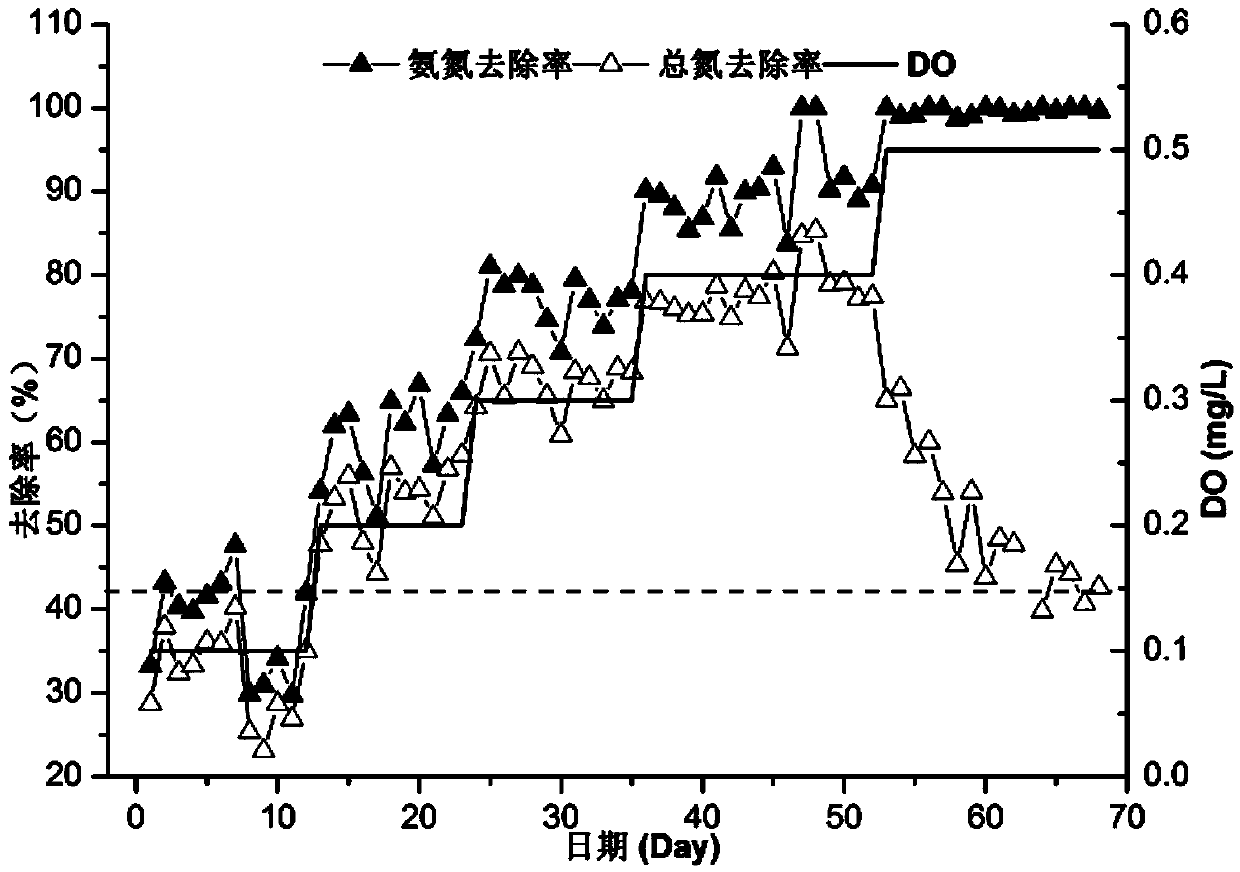

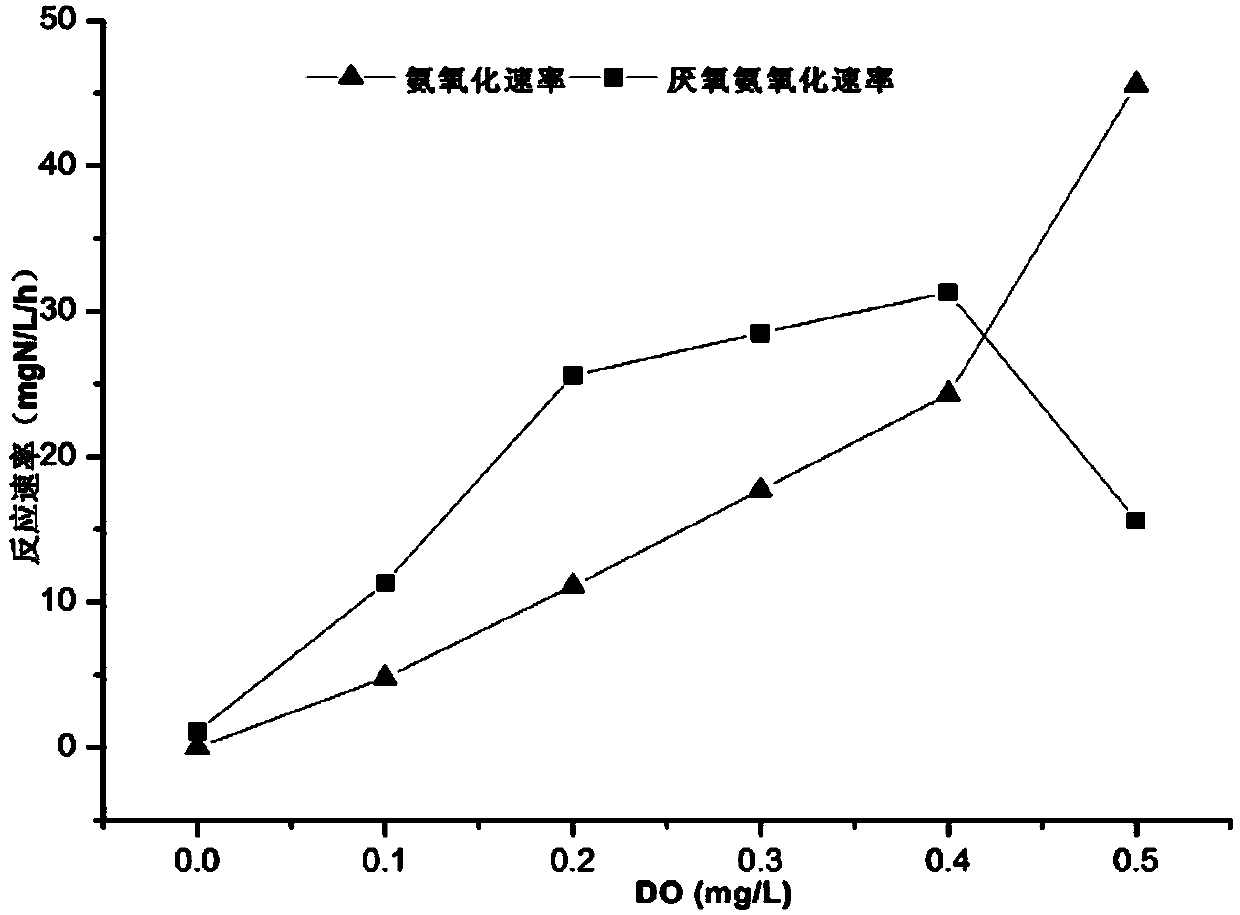

[0042] The operation mode includes five stages of water intake, reaction, sedimentation, drainage and idleness. The water is fed from the upper part by a peristaltic pump; in the reaction stage, the water temperature is controlled at 30±1°C, and the aeration is controlled at five concentration gradients of 0.1, 0.2, 0.3, 0.4, and 0.5mg / L, pH8.0±0.1, and HRT is 11h ; Sedimentation ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com