Slicing mechanism for numerically controlled planer

A gantry planing and slicing technology, which is applied in the direction of planer, planer/slotting machine, metal processing equipment, etc., can solve the problems of affecting processing accuracy, poor stability of gantry planer, low efficiency, etc., to improve service life and reduce carrying load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

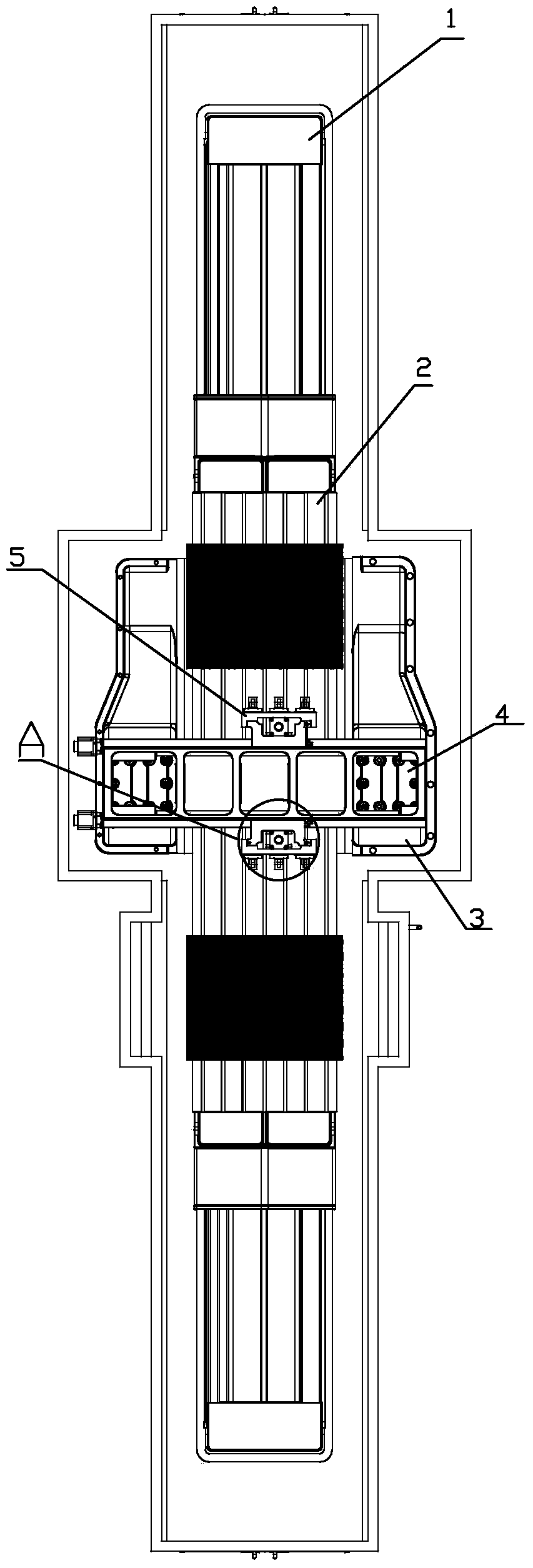

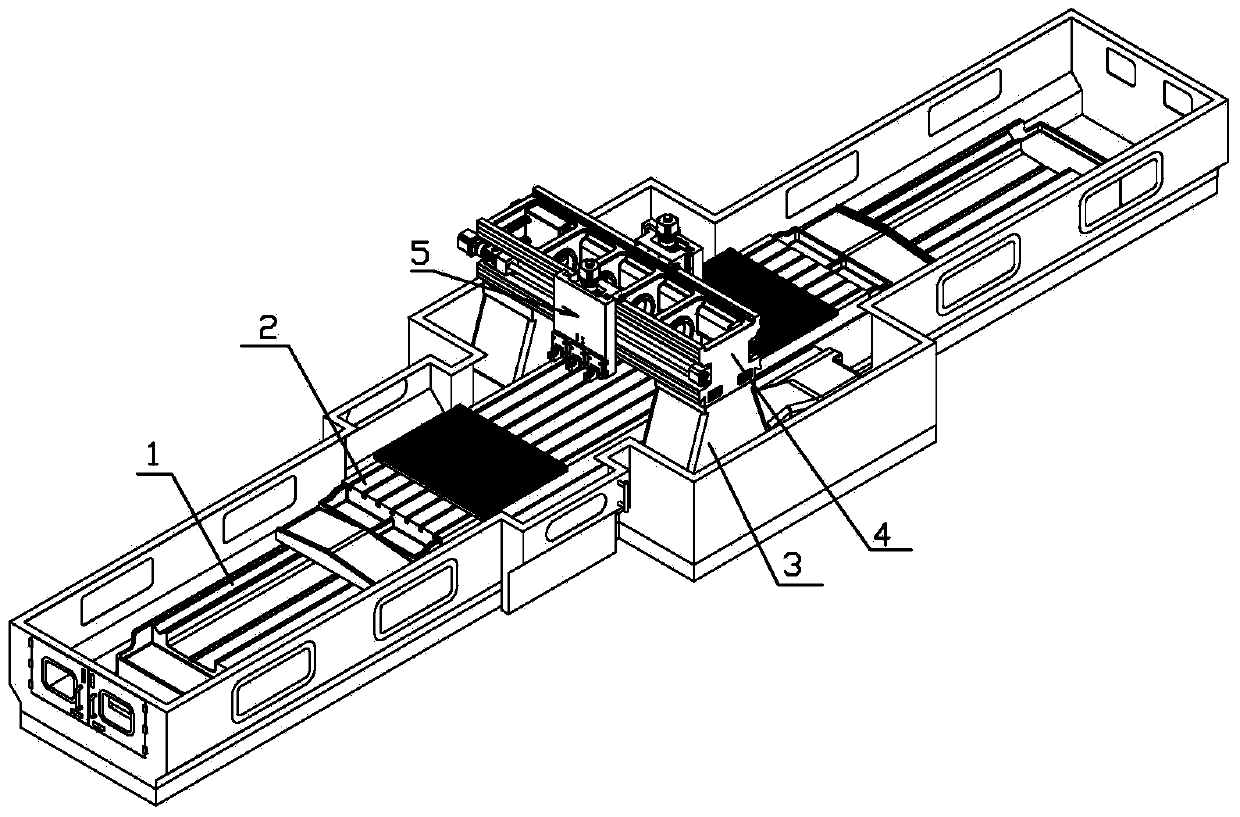

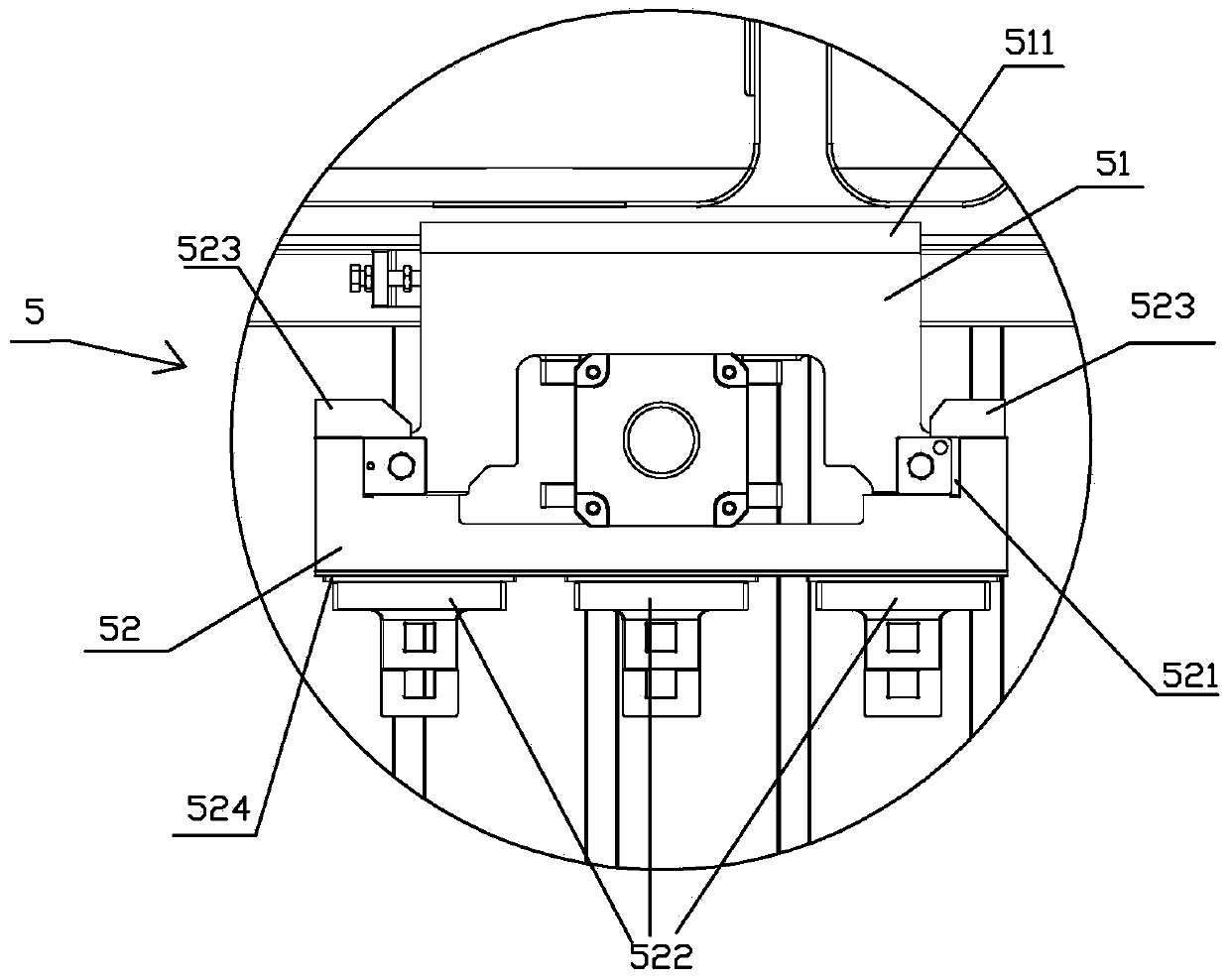

[0020] Embodiment: a kind of planing mechanism that is used for numerical control planer, as image 3 , 4 , 5, the slicing mechanism 5 includes a horizontal feed slide 51 and a lifting carriage 52, the horizontal feed slide 51 is provided with a screw B, and the screw B is threadedly connected with a screw nut. The rod nut is fixedly installed on the horizontal feed slide 51 through the nut seat; the screw C and the motor C are installed on the horizontal feed slide 51, and the lifting carriage 52 is installed on the horizontal feed slide 51 and can be moved horizontally. Slide up and down vertically for slide seat 51, and described vertical direction refers to figure 1 In the direction perpendicular to the longitudinal and transverse directions at the same time, the screw C is vertically installed on the horizontal feed slide 51 through the bearing and the bearing seat, the screw C is threadedly connected with the screw nut C, and the screw nut C is set through the nut seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com