Binder-free zsm-5 molecular sieve catalyst and its preparation and use method

A ZSM-5, binder-free technology, applied in the field of molecular sieve catalysts, can solve the problems of reduced catalytic activity and reduced utilization of molecular sieve channels, and achieve the effects of increased yield, improved catalytic cracking effect, and low methane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

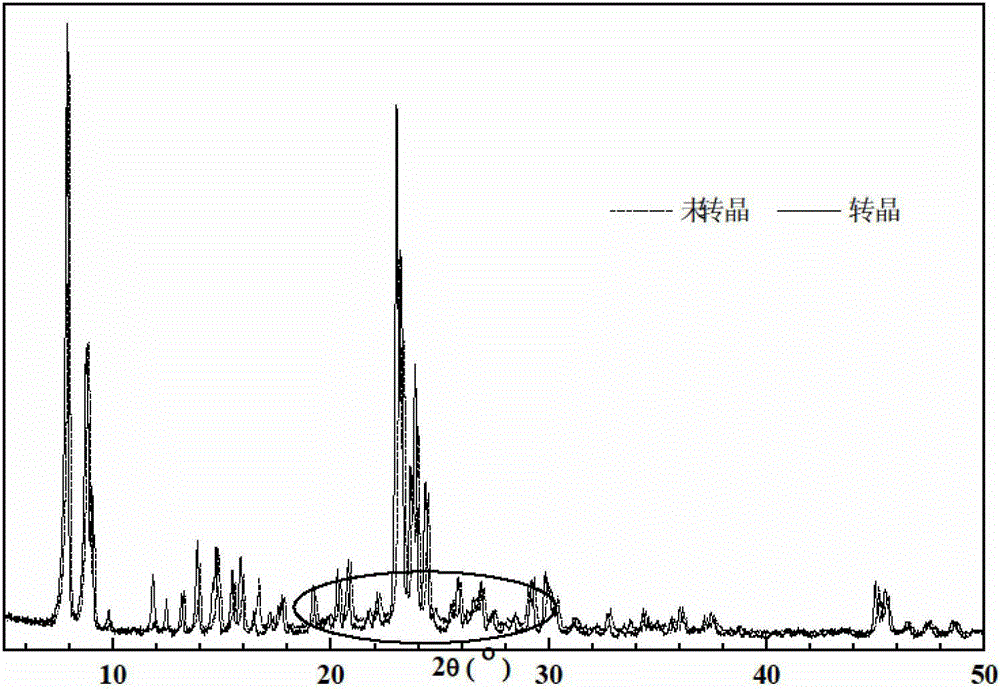

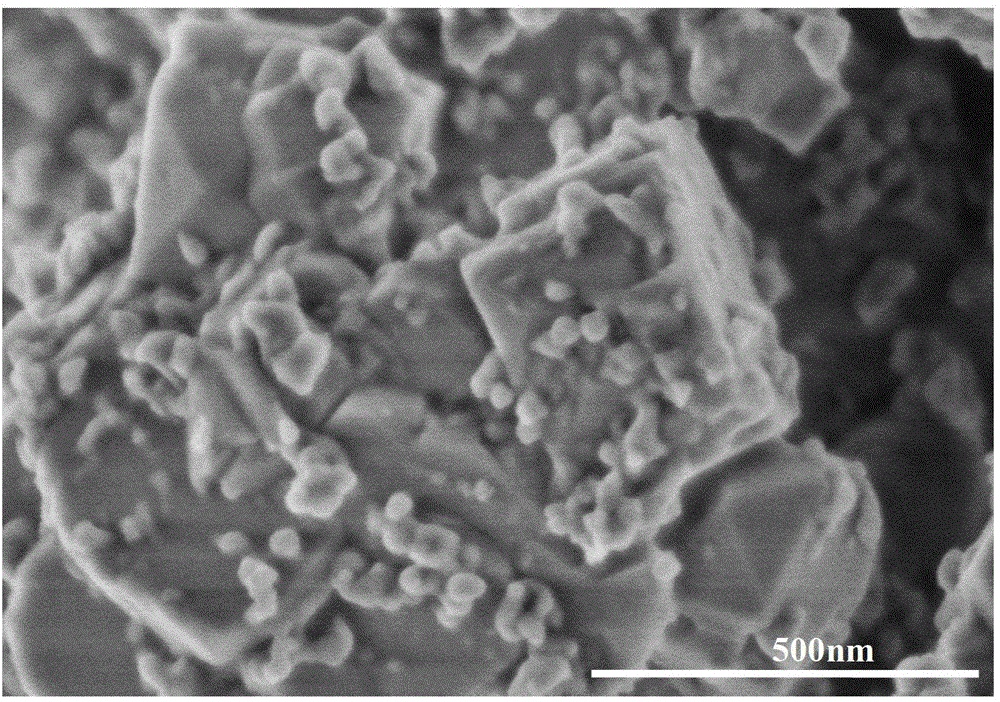

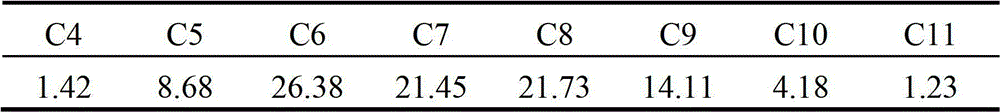

[0031] Mix ZSM-5 molecular sieve with a silicon-aluminum molar ratio of 50 and powdered silica 3:1 (weight ratio) evenly, add a solution containing phosphorus and lanthanum, and stir evenly. Knead and extrude into strips and let dry. Put it into the crystallization kettle, the mixture of 10 grams of triethylamine and 10 grams of water has been in the crystallization kettle, and there is a mesh metal object to isolate the liquid from direct contact with the strip. Stand at 180°C for 96 hours. Take it out, wash it with distilled water, dry it in the air, and bake it at 580°C. Sampling, pulverization and characterization. In the shaped catalyst, the weight content of phosphorus element is 1.25%, and that of lanthanum element is 0.67%. XRD characterization results show that (see figure 1 ), ZSM-5 crystal phase structure, and high crystallinity. In addition, at 22~28°, compared with the untransformed catalyst strip, it can be seen that the content of amorphous silica is signif...

Embodiment 2

[0036] Mix ZSM-5 molecular sieve with a silicon-aluminum molar ratio of 200 and powdered silicon dioxide 4:1 (weight ratio) evenly, add a solution containing phosphorus and lanthanum, and stir evenly. Knead and extrude into strips and let dry. Put it into the crystallization kettle, the mixture of 10 grams of triethylamine and 10 grams of water has been in the crystallization kettle, and there is a mesh metal object to isolate the liquid from direct contact with the strip. Place at 180°C for 48 hours. Take it out, wash it with distilled water, dry it in the air, and bake it at 580°C. In the shaped catalyst, the weight content of phosphorus element is 1.35%, and that of lanthanum element is 0.52%. Catalyst treatment and reaction conditions are the same as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0038] Mix ZSM-5 molecular sieve with a silicon-aluminum molar ratio of 350 and powdered silica 5:1 (weight ratio), add a solution containing phosphorus and lanthanum, and stir evenly. Knead and extrude into strips and let dry. Put it into the crystallization kettle, the mixture of 10 grams of triethylamine and 10 grams of water has been in the crystallization kettle, and there is a mesh metal object to isolate the liquid from direct contact with the strip. Stand at 180°C for 150 hours. Take it out, wash it with distilled water, dry it in the air, and bake it at 580°C. In the shaped catalyst, the phosphorus element weight content is 1.18%, and the lanthanum element is 0.60%. Catalyst treatment and reaction conditions are the same as in Example 1, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com