Supported oxidized graphene/metal organic framework composite material and preparation method thereof

A metal-organic framework and composite material technology, which is applied in the synthesis and application of supported graphene oxide/metal-organic framework composite materials, can solve the problems of unsatisfactory experimental controllability, reduction and disappearance of hydrogen overflow effect, etc. Achieve the effect of improving hydrogen absorption/desorption level, improving controllability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 2g of copper nitrate and 1g of trimesic acid in 17mL of N,N'-dimethylformamide, add 17mL of ethanol and 17mL of deionized water under stirring, and then add 0.15 x Graphene oxide loaded with Pt (the mass fraction of Pt is 20%, the particle size of Pt particles is 3-4nm), stirred evenly and ultrasonically dispersed for 15min, the obtained reaction solution was raised from room temperature to 100°C, keep the temperature for 4 hours, then cool to room temperature naturally. The product after suction filtration was immersed in dichloromethane for 2 times / 3 days, centrifuged at 3000r / h for 15min, and dried at 170°C for 36h to obtain a supported graphene oxide / metal organic framework composite material.

Embodiment 2

[0032] Will 1 g copper sulfate and 1 g Dissolve trimesic acid in 17 mL of N,N′-dimethylformamide, add 8.5 mL of ethanol and 8.5 mL of deionized water while stirring, and then add 0.20 g Graphene oxide loaded with Pt (the mass fraction of Pt is 20%, the particle size of Pt particles is 3-4nm), stirred evenly and ultrasonically dispersed for 30min, the obtained reaction solution was raised from room temperature to 95°C, after constant temperature for 6h, cool to room temperature naturally. The product after suction filtration was immersed in dichloromethane for 3 times / 3 days, centrifuged at 5000r / h for 10min, and dried at 180°C for 24h to obtain a supported graphene oxide / metal organic framework composite material.

Embodiment 3

[0034]Dissolve 1.5g of copper nitrate and 1g of trimesic acid in 17mL of N,N′-dimethylformamide, add 13mL of ethanol and 13mL of deionized water under stirring, and then add 0.2g of Pt-loaded graphene oxide (Pt The mass fraction of the Pt particles is 20%, the particle size of the Pt particles is 3-4nm), stirred evenly and ultrasonically dispersed for 15min, the obtained reaction solution was raised from room temperature to 100°C at a rate of 8°C / h, and after constant temperature for 5h, naturally Cool to room temperature. The product after suction filtration was immersed in dichloromethane for 2 times / 3 days, centrifuged at 4000r / h for 12min, and dried at 160°C for 30h to obtain a supported graphene oxide / metal organic framework composite material.

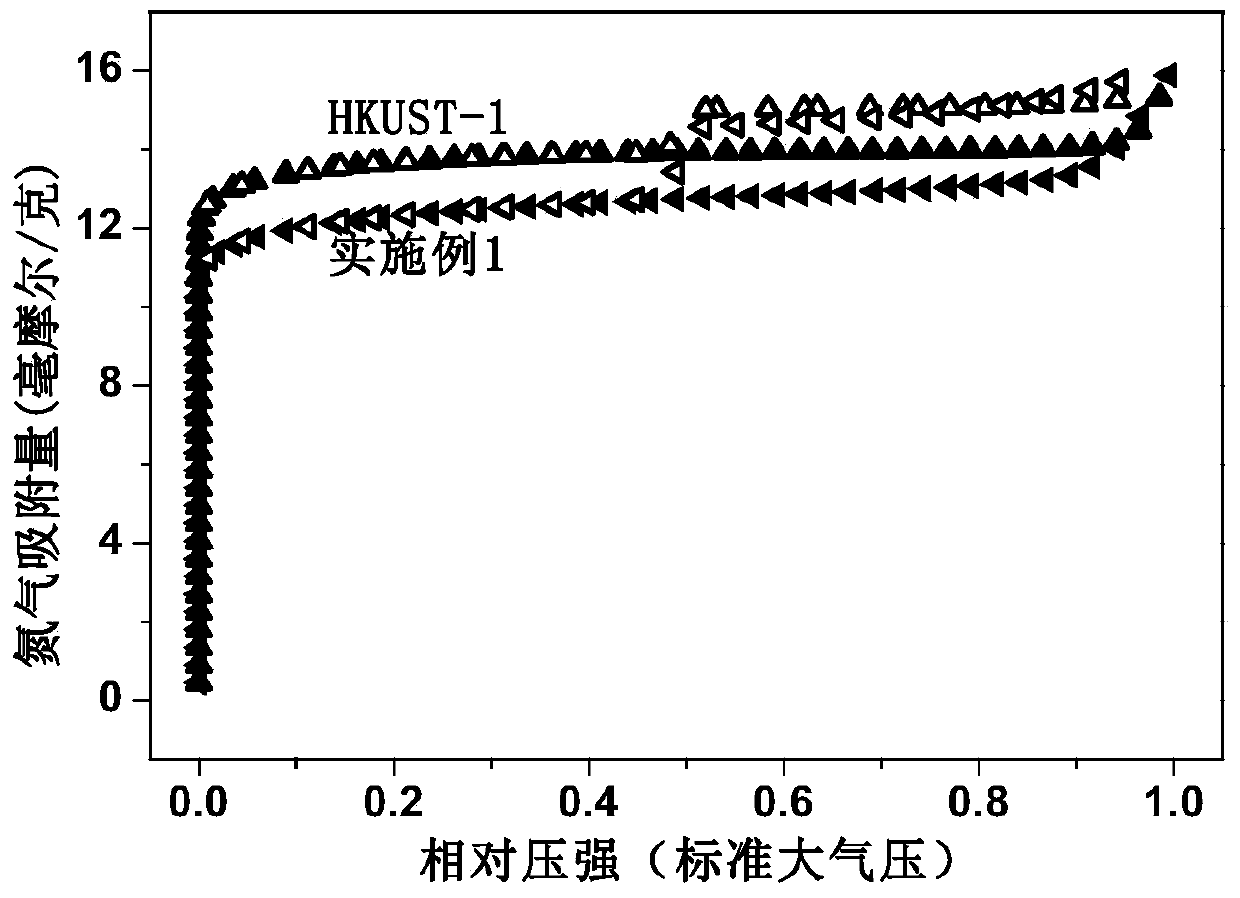

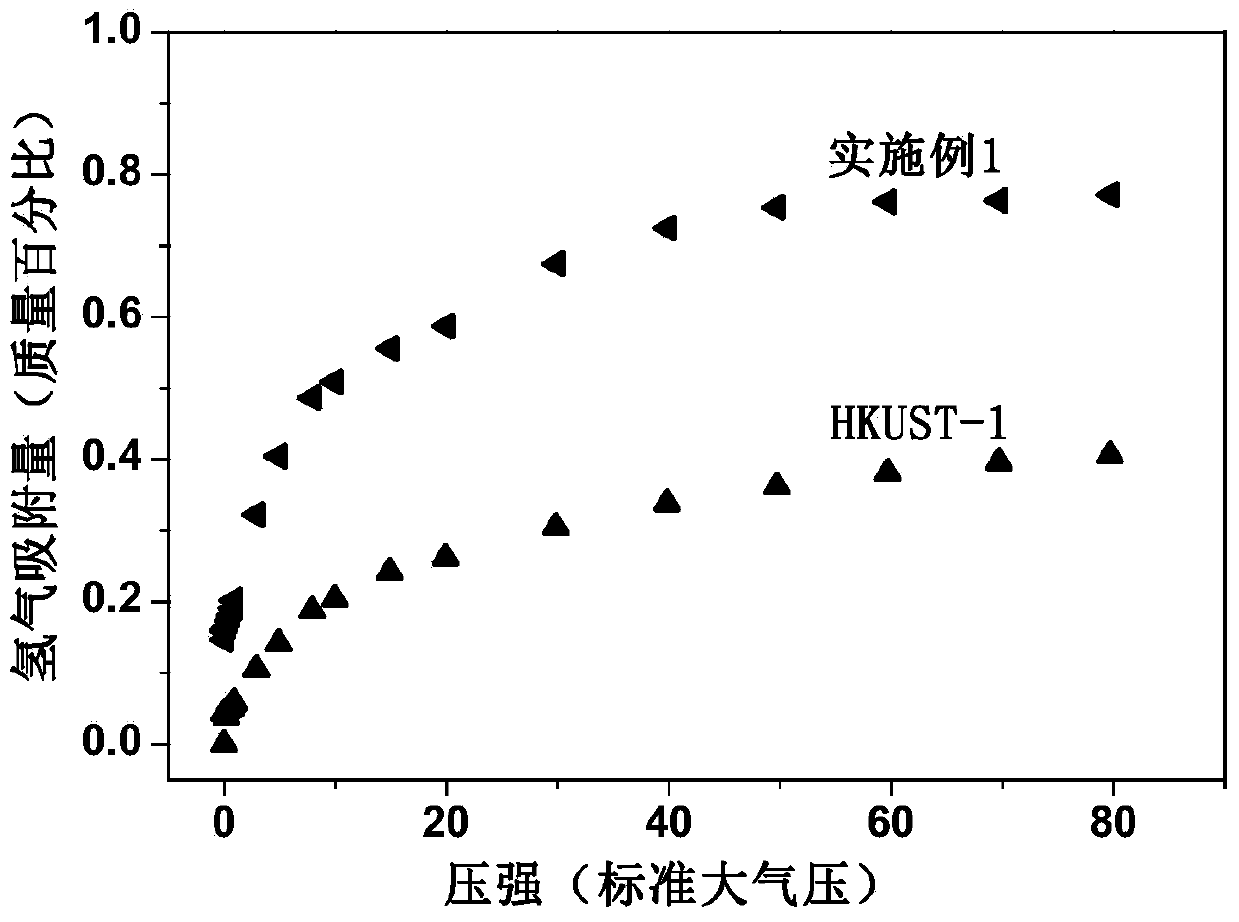

[0035] Characterization of Example 1

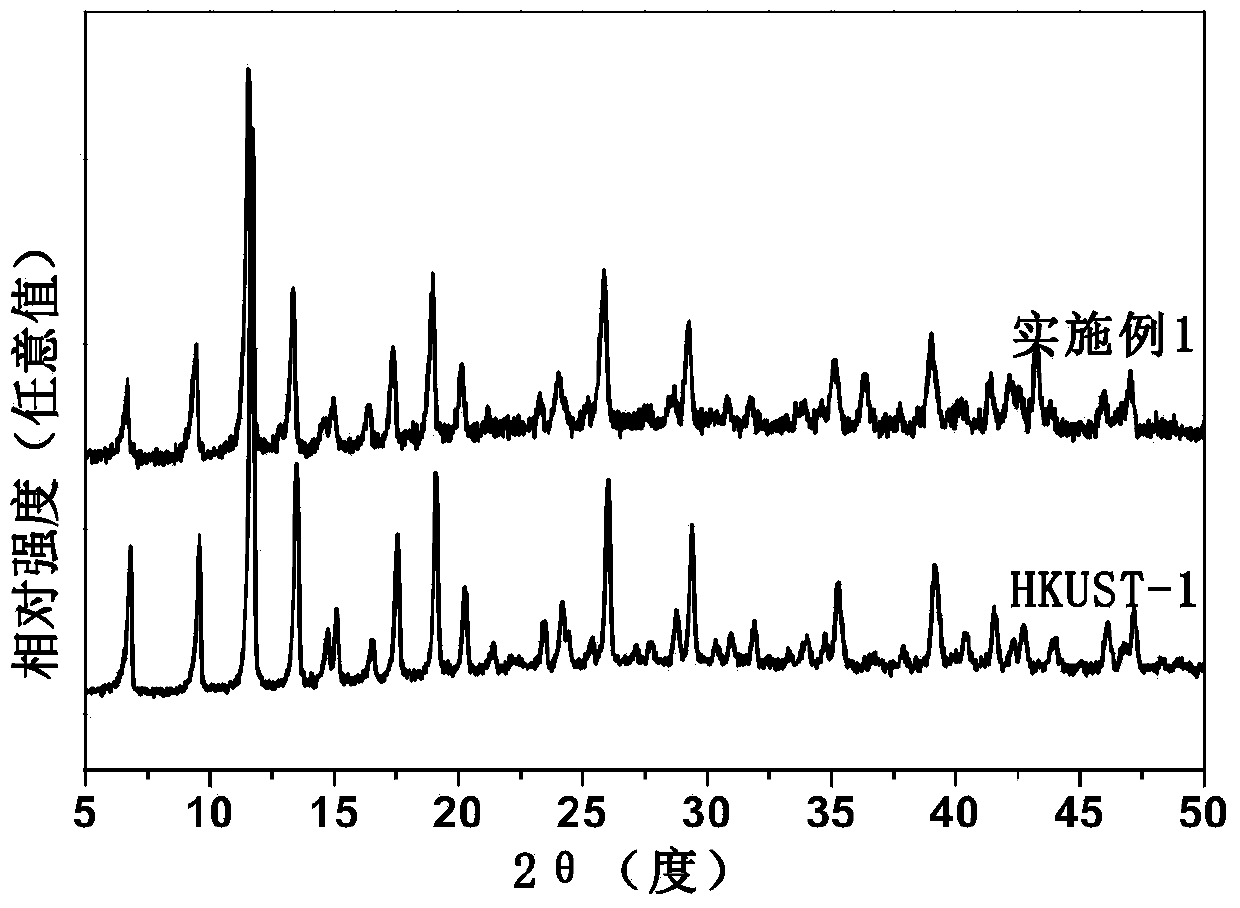

[0036] (1) Powder X-ray Diffraction Characterization of Example 1

[0037] The powder X-ray diffraction data collection of Example 1 of the present invention was completed on XRD-6000 X-ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com