Facial mask and method for producing same

A manufacturing method and facial mask technology, applied in skin care preparations, chemical instruments and methods, pharmaceutical formulations, etc., can solve problems such as the difficulty of cosmetic liquid soaking into the skin, and achieve the effect of preventing absorption and good skin touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1. The composition of facial mask 1 in embodiment 1

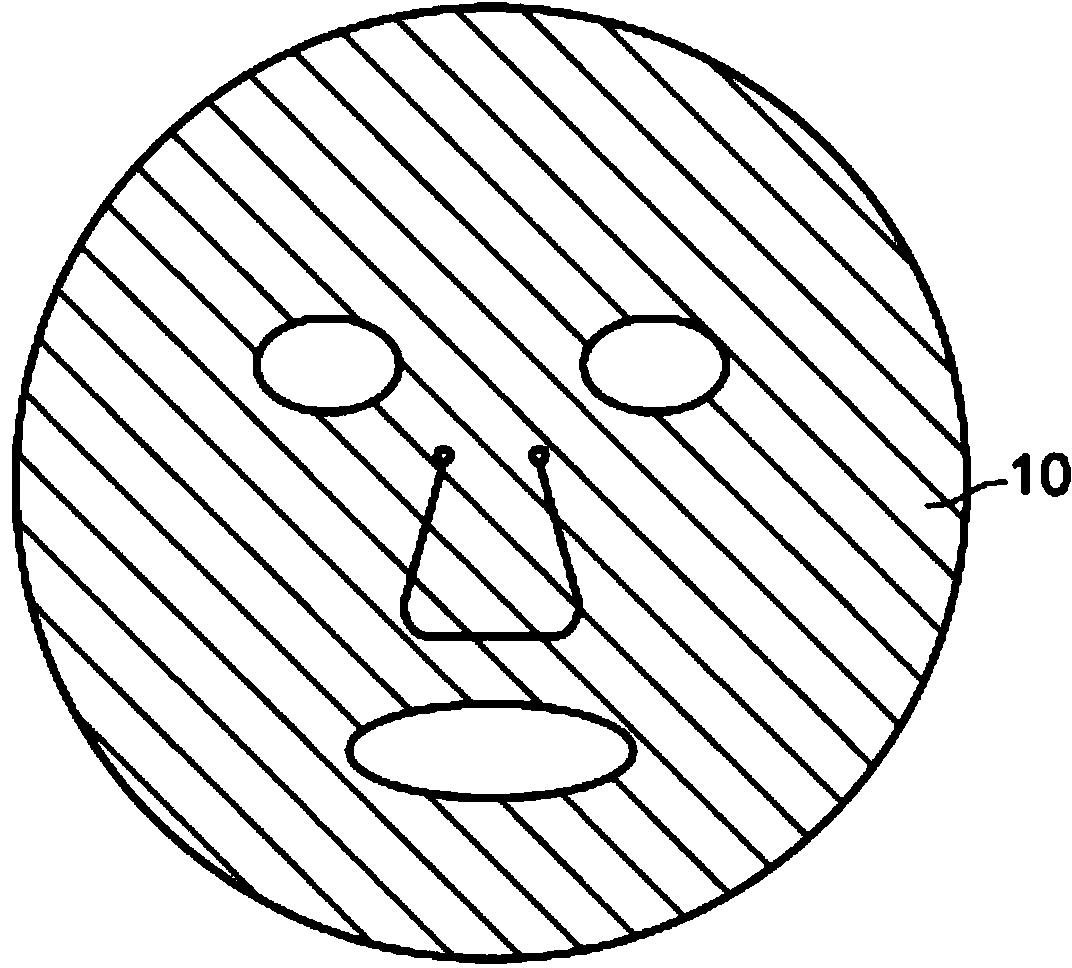

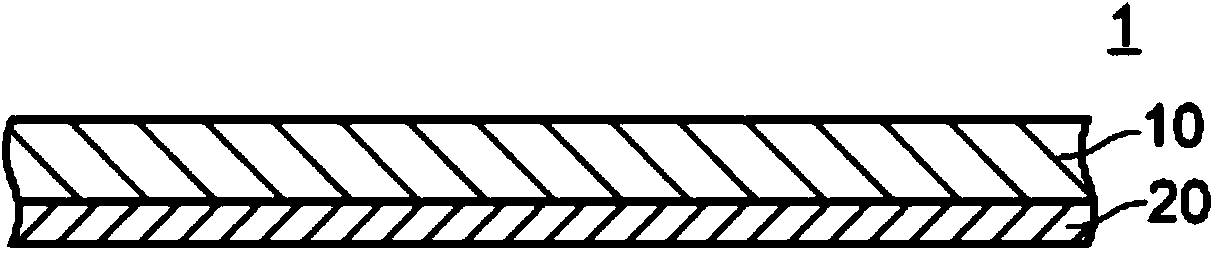

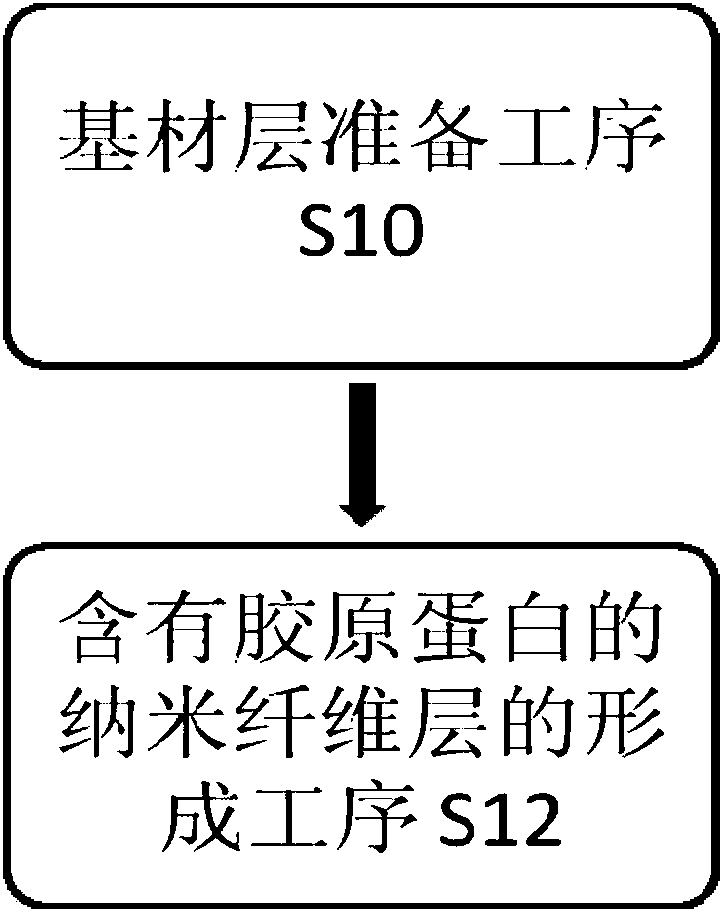

[0075] First, the structure of the mask 1 in Example 1 is demonstrated. Fig. 1 is the schematic diagram of facial mask 1 in embodiment 1. FIG. 1( a ) is an overall view of the mask 1 , and FIG. 1( b ) is a cross-sectional view of the mask 1 .

[0076] The facial mask 1 in embodiment 1 is a so-called peel-off facial mask. The facial mask is placed on the face for a period of time, and the dirt and the like on the face are removed when peeled off. As shown in Figure 1 (a), the facial mask 1 among the embodiment 1 has covered removing eyes, nose, all parts of the face except the mouth.

[0077] The facial mask 1 in Example 1 has a base material layer 10 and a collagen-containing nanofiber layer 20 as shown in FIG. 1( b ).

[0078] The base layer 10 is made of a nonwoven fabric and has hydrophilicity. The thickness ranges from 20 microns to 2 mm. Because when the thickness of the substrate layer 10 is below 20 micro...

Embodiment 2

[0118] Figure 4 It is a schematic illustration of the facial mask 2 in Example 2.

[0119] The facial mask 2 in Example 2 basically has a similar structure to the facial mask 1 in Example 1. Unlike the mask 1 composed of a nanofiber layer containing collagen, in the mask 2, the collagen C is impregnated with the nanofiber layer 22 not containing collagen.

[0120] The nanofiber layer 22 before being impregnated with collagen is composed of nanofibers not containing collagen. The thickness of the fiber layer 22 is between 5 microns and 50 microns. In addition, the diameter of nanofibers is between 1nm and 3000nm. The material of the fiber layer 22 is a material with high porosity and hydrophilicity, such as PVA. In addition, it is also possible to insolubilize PVA.

[0121] The nanofiber layer 22 containing collagen is obtained by impregnating the nanofiber layer 22 before impregnating collagen C. Specifically, the nanofiber layer 22 before being impregnated with collage...

Embodiment 3

[0131] Figure 5 It is a schematic illustration of the facial mask 3 in Example 3.

[0132] The facial mask 3 in the embodiment 3 basically has the same composition as the facial mask 1 in the embodiment 1, only the composition of the substrate layer is different from the facial mask 1. that is, Figure 5 As shown, the substrate layer 12 made of nanofibers and the nanofiber layer 20 containing collagen are laminated.

[0133] The base material layer 12 is different from the nanofibers used in the collagen-containing nanofiber layer. The fiber diameter of the substrate layer 12 is 1 nm to 3000 nm. The material of the base material layer 12 is a hydrophilic material, and in Example 3, PU is used.

[0134] In the substrate layer preparation process of Example 3, fibers different from those in the collagen-containing nanofiber layer were produced by electrospinning to form the substrate layer 12.

[0135] In this way, the substrate layer of the facial mask 3 in embodiment 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com