Natural forage yolk toner produced by orange peels and flavedo and preparation method thereof

A color enhancer and feeding technology, which is applied in the field of preparation of the feed egg yolk color enhancer, can solve the problems of poor palatability of fruit peel, high humidity and perishability, and low animal absorption rate of active ingredients, so as to improve the absorption effect and facilitate subsequent processing , Realize the effect of circular economy and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

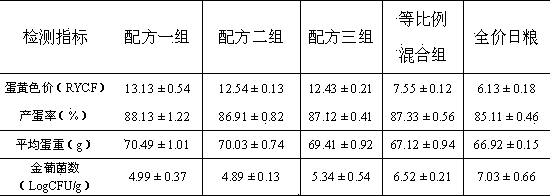

Embodiment 1

[0031] Embodiment 1, that is formula one, raw materials in parts by weight are: 44 parts of orange peel powder, 38 parts of orange peel powder, 12 parts of Haematococcus pluvialis powder, 6 parts of spinel chaetoceros powder, and 7 parts of auxiliary agent.

Embodiment 2

[0032] Embodiment 2, formula 2, the weight parts of raw materials are: 40 parts of orange peel powder, 41 parts of orange peel powder, 13 parts of Haematococcus pluvialis powder, 6 parts of spinel chaetoceros powder; 7 parts of auxiliary agent.

Embodiment 3

[0033] Embodiment 3, formula 3, the weight parts of raw materials are: 48 parts of orange peel powder, 30 parts of orange peel powder, 9 parts of Haematococcus pluvialis powder, 13 parts of spinel chaetoceros powder; 7 parts of auxiliary agent.

[0034] The preparation method is as follows: dry or dry orange peel, orange peel, Haematococcus pluvialis, and spinach chaetoceros, with a water content of 10-13%, and process and pulverize them with a high-speed pulverizer respectively, with a particle size of 60 mesh. Prepare the peel coarse powder; mix the raw material coarse powder evenly by weight and then mix evenly with the auxiliary agent, the auxiliary agent is composed of solid hydroxypropyl-β-cyclodextrin: kaolin = 19:1; after mixing the raw materials, use high-energy Vibration mill (volume 1.2 L; steel rod length 174 mm, diameter 18 mm) was used for processing, and the cooling water temperature was 19-21 ℃, the frequency was 16 Hz, and the steel rod acceleration was 8-9 g (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com