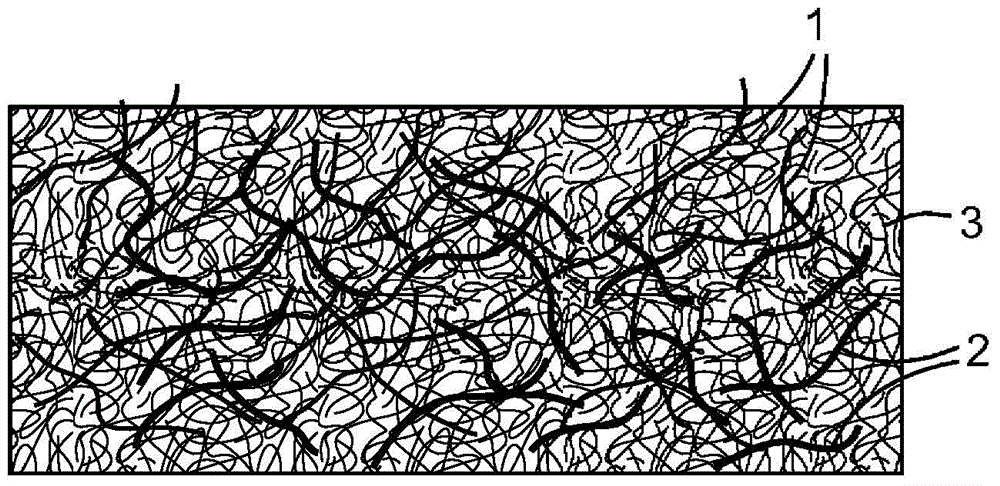

Nonwoven electret fiber web and its preparation method

A technology of electret and fiber web, which is applied in the direction of non-woven fabrics, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of ineffective elimination of odor, reduction, limited effectiveness of airborne particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0252] Notwithstanding that the numerical ranges and parameters setting forth the broad scope of the invention are approximations, the numerical values set forth in the specific examples are reported as precisely as possible. Any numerical value, however, inherently contains certain errors necessarily resulting from the standard deviation found in their respective testing measurements. At the very least, and not as an attempt to limit the application of the doctrine of equivalents to the scope of the claims, each numerical parameter should at least be construed in light of the number of reported significant digits and by applying ordinary rounding techniques.

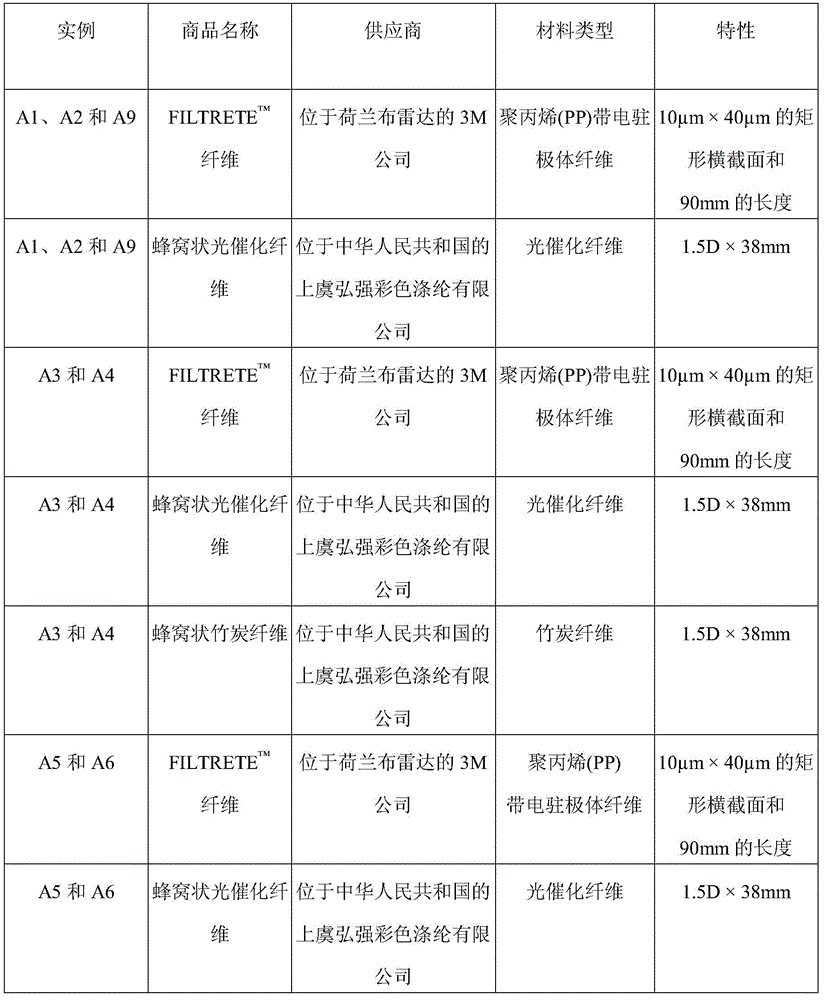

[0253] Material

[0254] The raw materials used in the following Preparation Examples, Examples and Comparative Examples are all commercially available, as detailed in Table A below.

[0255] Table A

[0256]

[0257]

[0258]

[0259]

[0260] The following fibers are exemplary filler fibers used in...

example A1

[0277] Nonwoven electret webs were prepared from 0.5 kg of electret fibers and 9.5 kg of photocatalytic fibers according to the processing procedure described below.

[0278] 1. First, the electret fibers and photocatalytic fibers are uniformly mixed, and then coarse opening and fine opening are performed respectively, wherein each opening roller has a frequency of 50 Hz in order to make the fiber blocks into fine fiber bundles. In addition, the impurities in the raw materials are filtered out.

[0279] 2. Then, the fiber bundle is sent to the carding machine via the feed box to card the fiber bundle into a single fiber arrangement state. The carded fibers were then output through a doffer to form a substantially uniform nonwoven electret web having a basis weight of 10 gsm.

[0280] 3. When the nonwoven electret fiber web is introduced into the cross-lapper, the number of laying layers is controlled by the speed of the cross-lapper and the conveyor belt to achieve the requir...

example A2

[0284] Nonwoven electret webs were prepared from 5 kg of electret fibers and 5 kg of photocatalytic fibers according to the processing procedure described below.

[0285] 1. First, the electret fibers and photocatalytic fibers are uniformly mixed, and then coarse opening and fine opening are performed respectively, wherein each opening roller has a frequency of 50 Hz in order to make the fiber blocks into fine fiber bundles. In addition, the impurities in the raw materials are filtered out.

[0286] 2. Then, the fiber bundle is sent to the Rando air-laid machine through the feed box, and the fiber bundle is made into a random state by processing the fiber bundle with a licker-in roller under the action of air flow. The output was a uniform nonwoven electret web having a basis weight of 90 gsm.

[0287] 3. Next, the laminated nonwoven electret web was subjected to needling at a needling frequency of 350 times / minute in order to increase the strength of the nonwoven electret web....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com