Method for producing an adhesive tape

A tape, tape-like technology, applied in the field of manufacturing tapes, capable of solving problems such as contact, hose casings that cannot be realized flawlessly, hose openings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

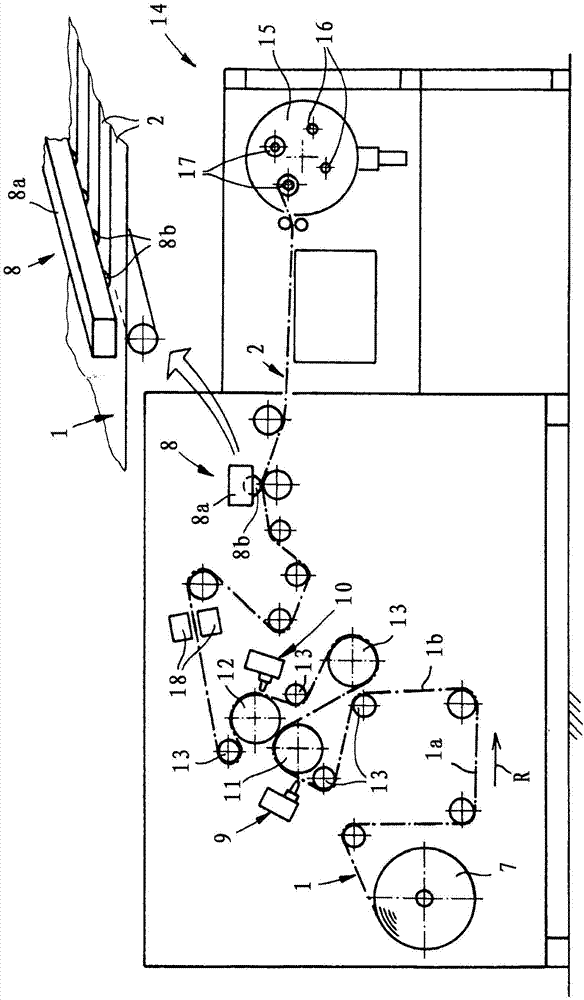

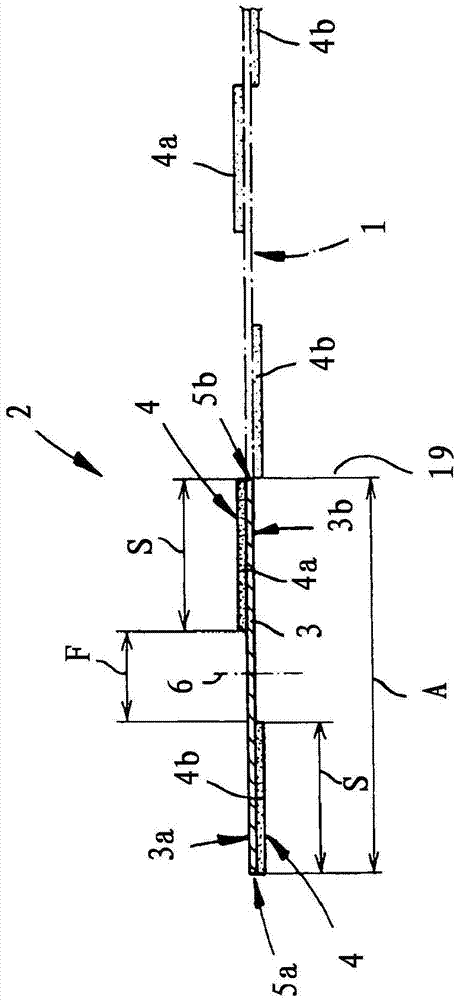

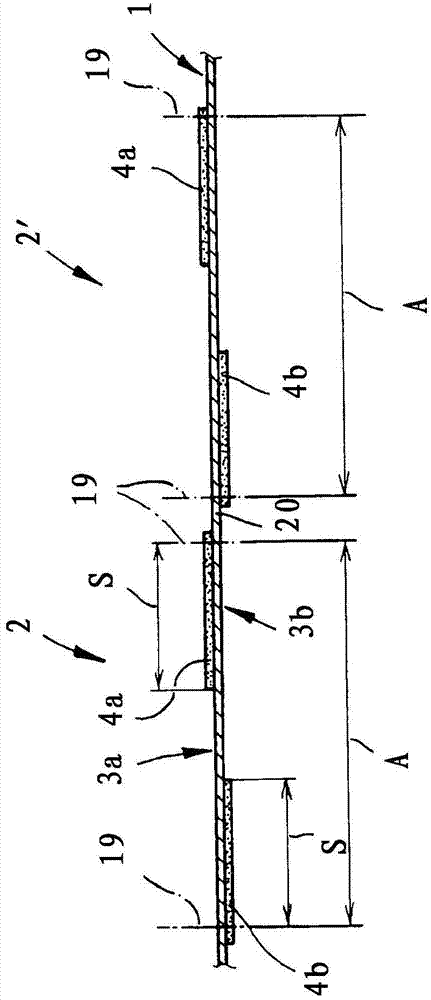

[0049] figure 1 shows a device by means of which one or more adhesive tapes 2 can be produced from the carrier web 1 on the outlet side. The principle structure of each adhesive tape 2 is in figure 2 and in Figures 3 to 5 is shown graphically.

[0050] In fact, the adhesive tape 2 has in its basic structure a carrier 3 and at least one adhesive strip 4 applied to the carrier 3 . in accordance with figure 2 Within the scope of the variant shown, the carrier 3 has associated adhesive strips 4 on both sides. A similar situation applies to Figures 3 to 5 Tape in 2. In practice here one adhesive strip 4a is arranged on the carrier top side 3a and another adhesive strip 4b is arranged on the carrier bottom side 3b.

[0051] In order to distinguish between the two adhesive strips 4, the adhesive strip 4 on the carrier top side 3a is referred to below as adhesive strip 4a, while the adhesive strip 4 on the carrier bottom side 3b bears the reference numeral 4b . The indivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com