A permanent magnet transmission device with a forced convection heat dissipation air-cooled cover

A technology of permanent magnet transmission and forced convection, which is applied in the direction of electromechanical transmission, cooling/ventilation device, electromechanical device, etc., can solve the problems of poor heat dissipation, high cost, and difficult sealing, and achieve reliable structural design, simple structure, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

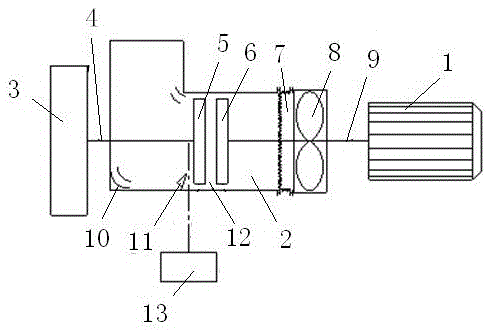

[0014] The present invention provides a permanent magnet transmission device with a forced convection heat dissipation air-cooled cover, which is sequentially provided with a motor 1, an axial flow fan 8, a guide disk 6, a permanent disk 5, a load device 3, a guide disk 6 and An air gap 12 is formed between the permanent disks 5, the size of the air gap 12 is controlled by a controller 13, and an air-cooled cover 2 is arranged inside between the axial flow fan 8 and the load device 3, wherein the axial flow fan 8 and the guide disk 6 is installed on the drive shaft 9, the permanent disk 5 and the load device 3 are mounted on the driven shaft 4, and the drive shaft 9 and the driven shaft 4 protrude from the air-cooled cover 2 to connect with the motor 1 and the load device 3 respectively.

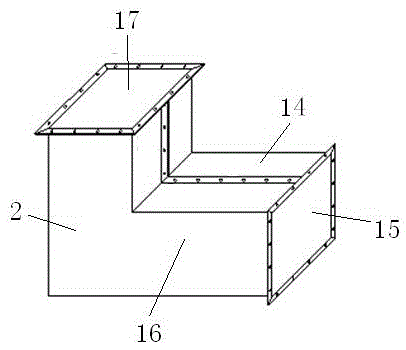

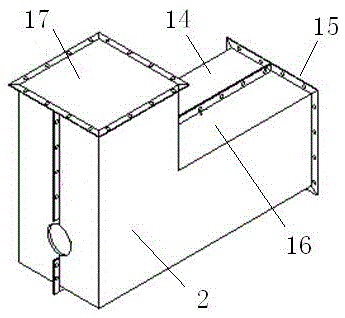

[0015] The air-cooled cover 2 is composed of a left housing 14 and a right housing 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com